La-doped TiO2 nano-catalysis material used for low-temperature plasma catalysis synergistic effect

A nano-catalytic material, low-temperature plasma technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. Insufficient rate and other problems, to achieve the effect of good catalytic effect, improved quantum yield and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

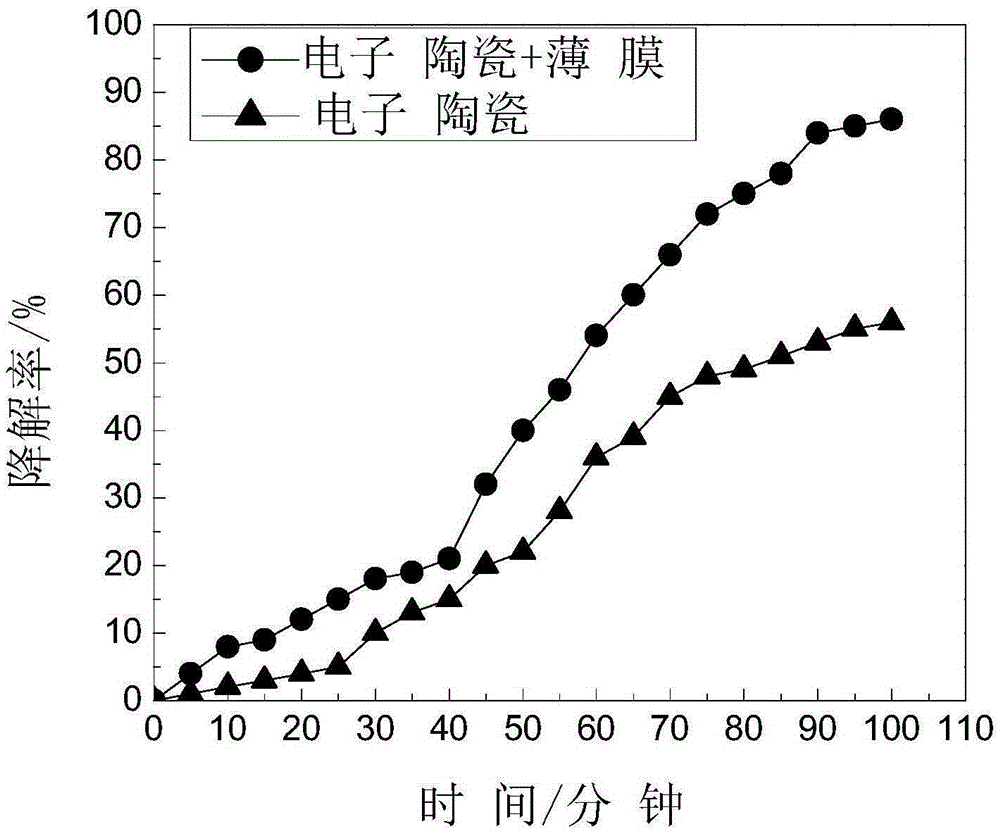

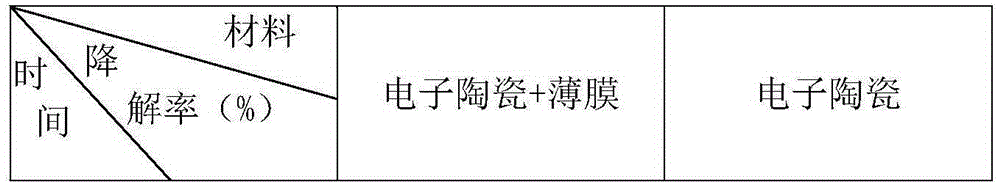

Image

Examples

Embodiment

[0024] La-doped TiO for low-temperature plasma-catalyzed synergy was prepared by the following steps 2 Nano catalytic materials:

[0025] (1) Add 10 ml of butyl titanate to the reactor, then slowly add 25 ml of absolute ethanol while stirring the butyl titanate to obtain a mixed solution, stir the mixed solution vigorously for 2 hours, then add 0.4 g of polyethylene Diol (20000), continue to stir for 30 minutes, obtain solution A;

[0026] (2) 25 milliliters of absolute ethanol and 1 milliliter of deionized water were mixed evenly, and then 100 milligrams of lanthanum nitrate and 2 milliliters of nitric acid were added successively, and the pH was controlled to be 2-3 to obtain solution B;

[0027] (3) solution B is added dropwise in the solution A of stirring, continue to stir for 2 hours, obtain Ti0 2 Sol;

[0028] (4) the prepared Ti0 2 The sol was sealed and placed for 10 hours in order to prepare the film;

[0029] (5) Coating with the ceramic electrode material as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com