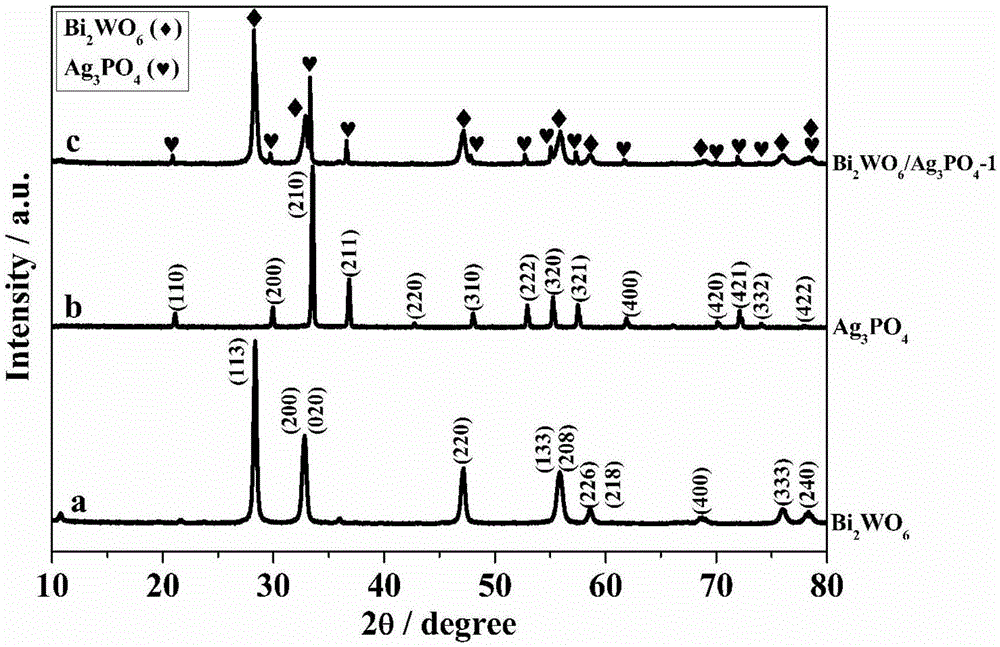

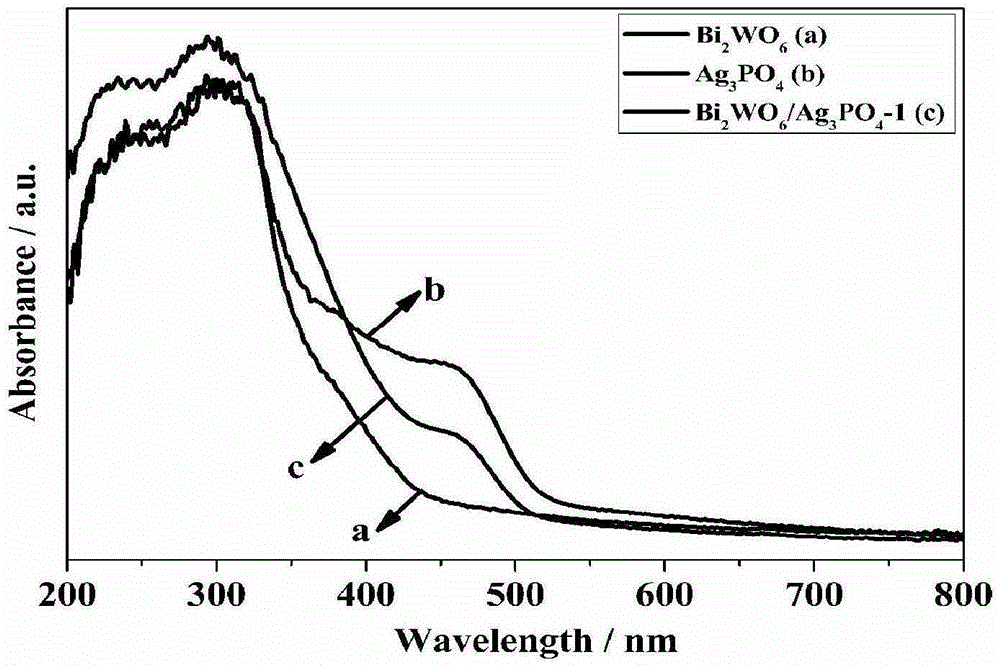

Bi2WO6/Ag3PO4 heterojunction composite photocatalyst and preparation method and application thereof

A technology of composite light and catalyst, applied in the field of photocatalysis, can solve the problems of unfavorable electron-hole rapid separation, increased probability of bulk recombination, low photocatalytic activity, etc., achieve good visible light absorption performance, reduce the probability of recombination, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

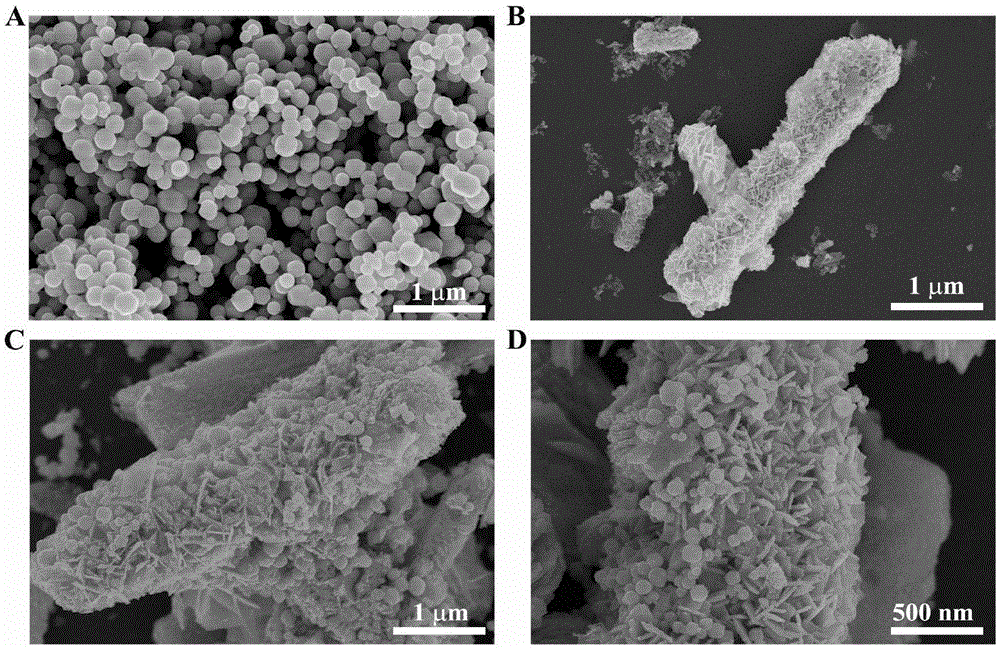

[0042] Bi 2 WO 6 / Ag 3 PO 4 Preparation method of heterojunction composite photocatalyst:

[0043] (1) Preparation of Bi with three-dimensional layered rod-like structure by hydrothermal synthesis 2 WO 6 : Weigh 5.0mmolBi (NO 3 ) 3 ·5H 2 O was added to 30mL ultrapure water, ultrasonically dispersed for 30min, and then magnetically stirred for 30min to obtain a dispersion; at the same time, 5.0mmolNa 2 WO 4 2H 2 O was added to 30.0mL ultrapure water, and magnetically stirred until it was completely dissolved to obtain a solution; 3 ) 3 The above Na was added dropwise to the dispersion 2 WO 4 solution, to obtain a suspension, and then use 2.0mol / LNH 3 ·H 2 O solution adjusts the pH of the suspension to 7, and then continues to stir for 60 minutes; after the stirring is completed, transfer the suspension to a high-pressure reactor equipped with a polytetrafluoroethylene liner, and put it in an electric constant temperature blast drying oven for heat treatment at 16...

Embodiment 2

[0052] Bi 2 WO 6 / Ag 3 PO 4 Preparation method of heterojunction composite photocatalyst:

[0053] Prepared by in-situ precipitation method, the difference from Example 1 is that the control of Bi 2 WO 6 with Ag 3 PO 4 The molar ratio is 1:0.75, weigh the above-mentioned 1.0mmolBi 2 WO 6 Add it into 30mL ultrapure water, ultrasonically disperse for 30min, and then magnetically stir for 30min to obtain a dispersion; then weigh 2.25mmolAgNO 3 Added to the above Bi 2 WO 6 In the dispersion liquid, stir until it is completely dissolved to obtain a mixed liquid; at the same time, add 0.75mmolNa 2 HPO 4 12H 2 O was added to 30mL ultrapure water, and magnetically stirred to make it dissolve completely to obtain a solution; then the above-mentioned Na 2 HPO 4 The solution was added dropwise to the above Bi 2 WO 6 with AgNO 3 In the mixed solution, continue to stir at room temperature in the dark for 5 hours; after the stirring is completed, the product is filtered by...

Embodiment 3

[0055] Bi 2 WO 6 / Ag 3 PO 4 Preparation method of heterojunction composite photocatalyst:

[0056] Prepared by in-situ precipitation method, the difference from Example 1 is that the control of Bi 2 WO 6 with Ag 3 PO 4 The molar ratio is 1:0.5, weigh the above-mentioned 1.0mmolBi 2 WO 6 Add it into 30mL ultrapure water, ultrasonically disperse for 30min, and then magnetically stir for 30min to obtain a dispersion; then weigh 1.5mmolAgNO 3 Added to the above Bi 2 WO 6 In the dispersion liquid, stir until it is completely dissolved to obtain a mixed liquid; at the same time, add 0.5mmolNa 2 HPO 4 12H 2 O was added to 30mL ultrapure water, and magnetically stirred to make it dissolve completely to obtain a solution; then the above-mentioned Na 2 HPO 4 The solution was added dropwise to the above Bi 2 WO 6 with AgNO 3 In the mixed solution, continue to stir at room temperature in the dark for 5 hours; after the stirring is completed, the product is filtered by su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com