Melting furnace and die-casting machine assembly line automatic casting system

A melting furnace and die-casting machine technology, applied in the field of mechanical casting processing, can solve the problems of inaccurate casting aluminum liquid dosage and low casting intelligence, and achieve the effects of solving the loss of molten metal, improving efficiency, and saving energy resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

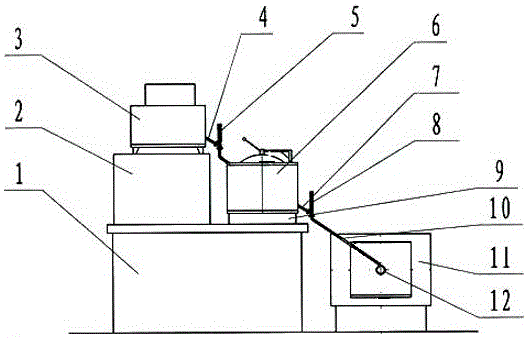

[0011] Depend on figure 1 It can be seen that the automatic casting system of the melting furnace and the die-casting machine line includes the melting furnace 3, the casting machine 11, and the computer and display screen not shown in the figure. The pouring and holding furnace 6 is set between the melting furnace 3 and the casting machine 11, and the three are connected to each other through pipes. The heights of the three are from high to low. On the working platform 1, the casting machine 11 is placed on the ground; the bottom of the pouring and holding furnace is equipped with an electronic scale 9, and the bottom of the pouring and holding furnace 6 is higher than the casting machine; the lower part of the melting furnace 3 is open, and the aluminum liquid flows into the control valve 1 through the feeding pipe 4 , the control valve one 5 is connected to the computer to realize automatic control, and the melted aluminum liquid enters the pouring and holding furnace 6 smo...

Embodiment 2

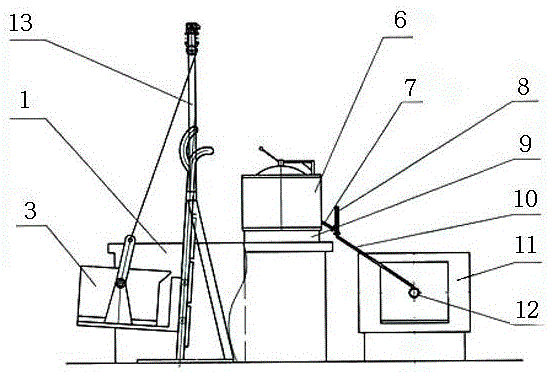

[0013] Depend on figure 2 It can be seen that the smelting furnace 3 is placed next to the pouring and holding furnace 6. If the conditions are limited, the smelting furnace 3 can be placed at a position far away from the pouring and holding furnace 6, and the smelting furnace 3 and the furnace in the furnace are connected by a lifting device 13 or other hoisting equipment. The aluminum water is lifted or hoisted as a whole, and the aluminum water in the melting furnace 3 is poured into the casting and holding furnace 6, and the constant temperature and heat-preserving aluminum water in the pouring and holding furnace 6 directly enters the feeding cylinder in the die-casting machine 11 through the discharge pipe 7 and the control valve 2 8 12. The computer controls the weight of the inflowing aluminum liquid and the cycle time of the liquid through the control valve, and the die-casting machine automatically die-casts the product after receiving a certain amount of aluminum l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com