Impervious puncture-resistant PE, EVA and glass fiber waterproof roll for tunnels and construction method of impervious puncture-resistant PE, EVA and glass fiber waterproof roll

A glass fiber and waterproof membrane technology, which is applied in the fields of glass fiber waterproof membrane and its construction, waterproof membrane and its construction, tunnel impermeability and puncture resistance PE, EVA, and can solve the problems of poor compression resistance and deformation resistance, Affect the waterproof performance of the waterproof membrane, the broken membrane and other problems, to achieve the effect of easy operation, simple construction method and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

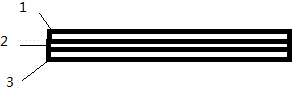

[0015] It can be seen from the attached drawings that the tunnel anti-seepage and puncture-resistant PE, EVA, and glass fiber waterproof membranes are composed of surface layer-isolation film protection layer 1, middle layer-PE layer, bottom layer-adhesive sealant layer 3, and the gap between each layer It is bonded together by heat and pressure during the production process.

[0016] The protective layer of the isolation film is polyvinyl chloride film, polyester film or release paper or other films with isolation protection, the thickness of the isolation film protective layer is 0.15-0.2cm, and the thickness of the adhesive sealant layer is 0.1-0.5cm.

[0017] The PE layer contains impact-resistant and puncture-resistant modifier EVA, and glass fiber is added to improve its breaking strength. The thickness of the PE layer is 0.5-3.0cm.

[0018] There are two construction methods for tunnel impermeable and puncture-resistant PE, EVA, and glass fiber waterproof membranes. One...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com