Preparation method for hydrophobic organic-modified silicate thin film with adjustable refractive index and silicate thin film

A thin film preparation and hydrophobic technology is applied in the field of hydrophobic organic modified silicate thin film and its preparation, which can solve the problems of increasing the process flow and cost, affecting the service life of the coating solution, and reducing the weather resistance of the thin film, and improving the porosity. The effect of increasing the rate, stability and service life, and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

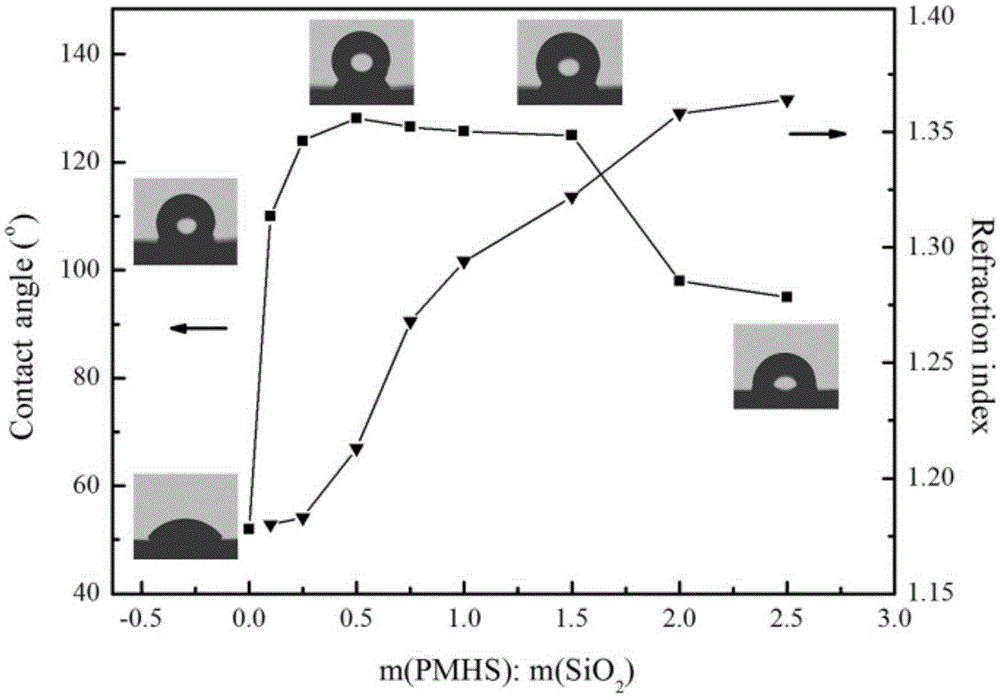

[0055] Control of PMHS content and SiO contained in primary coating solution 2 Mass ratio m(PMHS):m(SiO 2 )=0.1:1

[0056] The total aging time is 6 days.

[0057] The refractive index of the prepared film is 1.180; the water drop contact angle is 112°.

Embodiment 2

[0059] Control of PMHS content and SiO contained in primary coating solution 2 Mass ratio m(PMHS):m(SiO 2 )=0.5:1

[0060] Total aging time 10 days

[0061] The refractive index of the prepared film is 1.227; the water drop contact angle is 129°.

Embodiment 3

[0063] Control of PMHS content and SiO contained in primary coating solution 2 Mass ratio m(PMHS):m(SiO 2 )=0.75:1

[0064] Total aging time 30 days

[0065] The refractive index of the prepared film is 1.269; the water drop contact angle is 126°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com