A water-resistant composite oil phase specially used in the production process of liquid-mixed puffed explosives

A technology of composite oil phase and production process, which is applied in the direction of explosives, non-explosive/non-thermal agent components, offensive equipment, etc., can solve the problems of water resistance of puffed explosives and the inability to directly use puffed explosives, etc., to facilitate industrialization Production and application, convenient packaging, storage and transportation, and the effect of reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

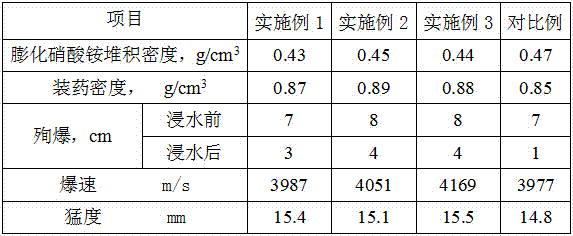

Embodiment 1

[0048] Subtract 47 parts of second-line wax paste, 20 parts of cotton oil tar, 8 parts of palmitic acid, 7 parts of pentaerythritol erucate, 15 parts of No. 60 semi-refined paraffin, and 3 parts of 18-amine acetate. Prepared in the following manner:

[0049] Add the second-line wax paste, cotton oil tar, palmitic acid, pentaerythritol erucate, No. 60 semi-refined paraffin, and 18-amine acetate into different melting tanks, and control the temperature of the different melting tanks at 80~90°C. temperature range and hold until all material is melted. Then, each material is measured according to the proportioning requirements by an oil pump and an electronic scale, and then pumped into the reactor respectively. The temperature of the reactor is raised to 100~110°C and the uniform stirring state in the reactor is maintained. At the same time, the vacuum pump is turned on to evacuate the reactor. Dehydration and filtration are carried out in sequence, and the filtered material is ...

Embodiment 2

[0051] Minus 50 parts of four-line wax paste, 15 parts of vegetable oil tar, 6 parts of stearic acid, 9 parts of pentaerythritol stearate, 18 parts of No. 60 semi-refined paraffin wax, and 2 parts of 18 amine acetate.

[0052] Prepared in the following manner:

[0053]Add minus four line wax paste, vegetable oil tar, stearic acid, pentaerythritol stearate, No. 60 semi-refined paraffin, and 18 amine acetate into different melting tanks, and control the temperature of different melting tanks at 80-90 °C temperature range and maintain until all materials are melted. Then, the materials are measured according to the proportion requirements by the oil pump and electronic scale, and then pumped into the reactor respectively, the temperature of the reactor is raised to 100~110°C and the uniform stirring state in the reactor is maintained, and the vacuum pump is turned on after the reaction of the materials is complete Vacuumize the kettle and perform dehydration and filtration opera...

Embodiment 3

[0055] Minus 45 parts of sanxian wax ointment, 19 parts of rice bran oil tar, 10 parts of erucic acid, 8 parts of pentaerythritol oleate, 15 parts of No. 60 semi-refined paraffin wax, 1.5 parts of 18-amine acetate, and 1.5 parts of 18-amine.

[0056] Add the three-line wax paste, rice bran oil tar, erucic acid, pentaerythritol oleate, No. 60 semi-refined paraffin, 18 amine acetate, and 18 amine into different melting tanks, and control the temperature of different melting tanks at 80~ within the temperature range of 90°C and hold until all materials are melted. Then, each material is measured according to the proportioning requirements by an oil pump and an electronic scale, and then pumped into the reactor respectively. The temperature of the reactor is raised to 100~110°C and the uniform stirring state in the reactor is maintained. At the same time, the vacuum pump is turned on to evacuate the reactor. Dehydration and filtration are carried out in sequence, and the filtered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com