Method for efficiently separating immunocompetence polysaccharide of ganoderma atrum

An immune activity and polysaccharide technology, applied in the field of extraction and separation of natural products, can solve the problems of incomplete separation, time-consuming, poor stability, etc., and achieve the effect of shortening purification time, improving purification efficiency, and excellent immune activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

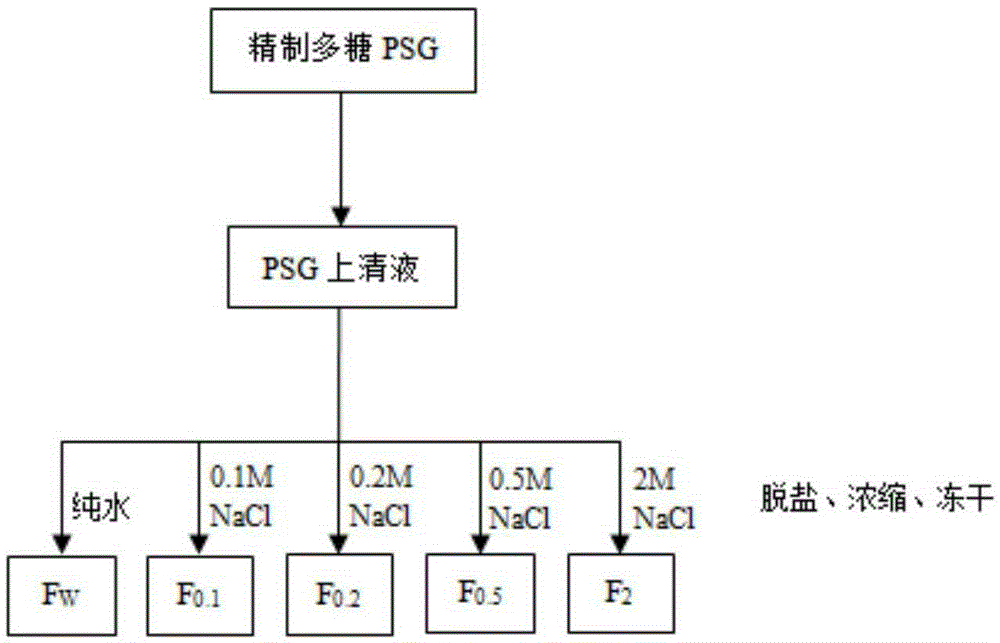

[0024] Weigh 60 mg of refined polysaccharide PSG sample, dissolve it in distilled water, and prepare a solution with a concentration of 3.0 mg / mL. Before sample injection, the sample solution is centrifuged (5000 rpm for 10 min) to remove insoluble matter; Put it into a Q-Sepharose FastFlow anion exchange column (1.5x10cm), let it seep down naturally, and fully exchange the sample with the resin for 10 minutes; Elute the unadsorbed samples with ultrapure water, and collect the eluent; the samples adsorbed on the resin are then eluted in stages with 0.1, 0.2, 0.5 and 2M NaCl solutions of 5 times the column volume, and the flow rate is controlled at 10mL The fractions of different stages were collected respectively; the eluents of five different fractions were concentrated, desalted by water dialysis, and freeze-dried to obtain separated and purified samples, which were recorded as Fw, Fw, and Fw respectively. 0.1 ,F 0.2 ,F 0.5 and F 2 , the sample recoveries were: 7.9%, 22.5...

Embodiment 2

[0026] Weigh 100 mg of the refined polysaccharide PSG sample, dissolve it in distilled water, and prepare a solution with a concentration of 5.0 mg / mL. Before sample injection, the sample solution is centrifuged (5000 rpm for 10 min) to remove insoluble matter; Put it into a Q-Sepharose FastFlow anion exchange column (1.5x10cm), let it seep down naturally, and fully exchange the sample with the resin for 10 minutes; Elute the unadsorbed samples with ultrapure water, and collect the eluent; the samples adsorbed on the resin are then eluted in stages with 0.1, 0.2, 0.5 and 2M NaCl solutions of 5 times the column volume, and the flow rate is controlled at 10mL The fractions of different stages were collected respectively; the eluents of five different fractions were concentrated, desalted by water dialysis, and freeze-dried to obtain separated and purified samples, which were recorded as Fw, Fw, and Fw respectively. 0.1 ,F 0.2 ,F 0.5 and F 2 , the sample recoveries were: 8.4%,...

Embodiment 3

[0028]Weigh 150 mg of refined polysaccharide PSG sample, dissolve it in distilled water, and prepare a solution with a concentration of 5.0 mg / mL. Before sample injection, the sample solution is centrifuged (5000 rpm for 10 min) to remove insoluble matter; Put it into a Q-Sepharose FastFlow anion exchange column (1.5x10cm), let it seep down naturally, and fully exchange the sample with the resin for 10 minutes; Elute the unadsorbed samples with ultrapure water, and collect the eluent; the samples adsorbed on the resin are then eluted in stages with 0.1, 0.2, 0.5 and 2M NaCl solutions of 5 times the column volume, and the flow rate is controlled at 10mL The fractions of different stages were collected respectively; the eluents of five different fractions were concentrated, desalted by water dialysis, and freeze-dried to obtain separated and purified samples, which were recorded as Fw, Fw, and Fw respectively. 0.1 , F 0.2 , F 0.5 and F 2 , the sample recoveries were: 8.1%, 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com