A 125°C high wear-resistant radiation cross-linked low-smoke halogen-free cable material and its preparation method

A cable material and high wear-resistant technology, applied in the field of wire and cable materials, can solve problems such as wear resistance of toxic and harmful gases, and achieve the effect of improving surface wear resistance and improving wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

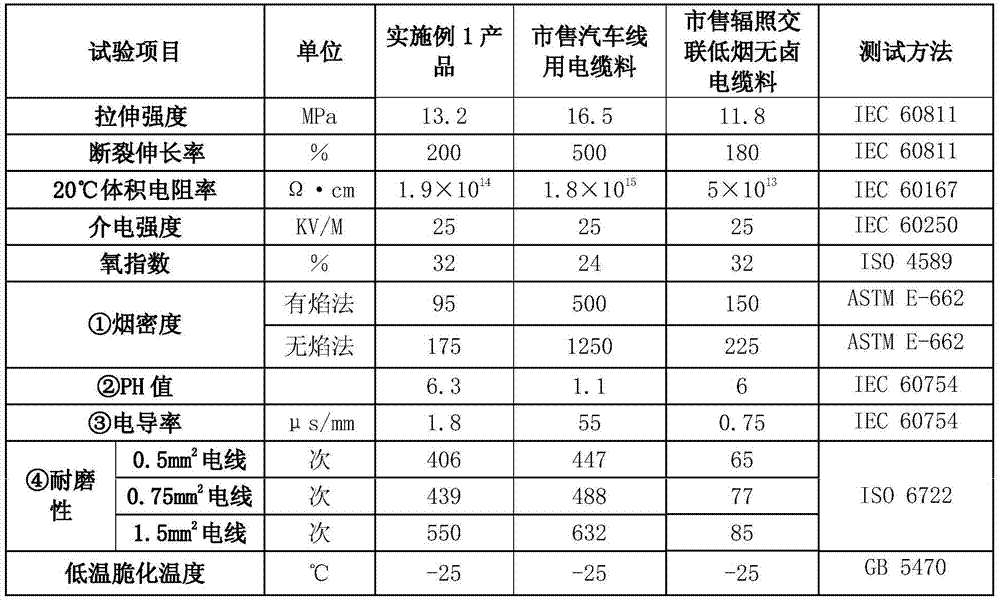

Embodiment 1

[0021] A 125°C high wear-resistant radiation cross-linked low-smoke halogen-free cable material, in terms of mass percentage, the components and the content of each component are: ethylene-vinyl acetate copolymer 12%, metallocene polyethylene 5% , Bimodal medium density polyethylene 15%, maleic anhydride grafted polyethylene 6%, aluminum hydroxide 58%, alkyl siloxane 1%, antioxidant additive 3%. The sum of the mass percentages of each component is 100%.

[0022] Among them, the density of metallocene polyethylene is 0.905g / cm 3 , the melt index is 4.0g / 10min; the vinyl acetate content of ethylene-vinyl acetate copolymer is 28g / cm 3 , the melt index is 3g / 10min; the density of bimodal medium density polyethylene is 0.923±0.003g / cm 3 , the melt index is 0.2g / 10min; the maleic anhydride grafted polyethylene graft rate is 0.7%, and the melt index is 1g / 10min; the antioxidant additive is tetrakis[β-(3,5-di-tert-butyl-4 -Hydroxyphenyl)propionic acid]pentaerythritol ester and dist...

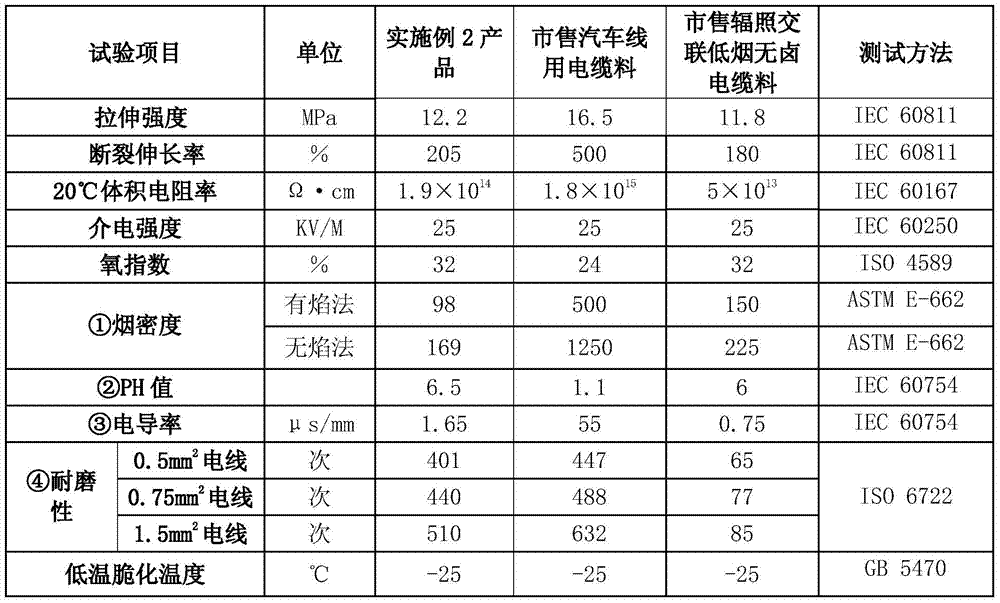

Embodiment 2

[0032] A 125°C high wear-resistant radiation cross-linked low-smoke halogen-free cable material, in terms of mass percentage, the components and the content of each component are: ethylene-vinyl acetate copolymer 22%, metallocene polyethylene 8% , bimodal medium density polyethylene 8%, maleic anhydride grafted polyethylene 4%, magnesium hydroxide 55%, alkyl siloxane 2%, antioxidant additive 1%, the sum of the mass percentages of each component is 100%.

[0033] Among them, the density of metallocene polyethylene is 0.905g / cm 3 , the melt index is 4.0g / 10min; the vinyl acetate content of ethylene-vinyl acetate copolymer is 26g / cm 3 , the melt index is 4g / 10min; the density of bimodal medium density polyethylene is 0.923±0.003g / cm 3 , the melt index is 0.15g / 10min; the graft rate of maleic anhydride grafted polyethylene is 0.8%, and the melt index is 1.2g / 10min; the antioxidant additive is tetrakis[β-(3,5-di-tert-butyl- 4-Hydroxyphenyl) propionate] pentaerythritol ester and ...

Embodiment 3

[0043] A 125°C high wear-resistant irradiation cross-linked low-smoke halogen-free cable material, in terms of mass percentage, the components and the content of each component are: ethylene-vinyl acetate copolymer 20%, metallocene polyethylene 7% , bimodal medium density polyethylene 14%, maleic anhydride grafted polyethylene 3%, a mixture of aluminum hydroxide and magnesium hydroxide 53%, alkyl siloxane 0.5%, antioxidant additive 2.5%, each component The sum of the mass percentages is 100%.

[0044] Among them, the density of metallocene polyethylene is 0.905g / cm 3 , the melt index is 4.0g / 10min; the vinyl acetate content of ethylene-vinyl acetate copolymer is 27g / cm 3 , the melt index is 2g / 10min; the density of bimodal medium density polyethylene is 0.923±0.003g / cm 3 , the melt index is 0.25g / 10min; the maleic anhydride grafted polyethylene graft rate is 0.9%, the melt index is 0.8g / 10min; the antioxidant additive is tetrakis [β-(3,5-di-tert-butyl- 4-Hydroxyphenyl) prop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com