Preparation method and application of extract of Baphicacanthus cusia Brem

A technology of indigo and its extract, which is applied in the research field of natural plant extracts, can solve the problems of environmental pollution, high toxicity of products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Wash, dry, and pulverize the cyanide grass to 25 meshes to obtain the cyanoid grass pulverization, and then add the cyandicyst grass pulverization to a pH value of 8, and a volume percentage concentration of 75% (V 乙醇 :V 水 ) in the aqueous ethanol solution to obtain the extraction system,

[0024] Wherein, the pH value of the aqueous ethanol solution is regulated by sodium bicarbonate, and the mass ratio of the edulis edulis to the aqueous ethanol solution is 1:20;

[0025] (2) Under stirring, the extraction system obtained in step (1) is heated up, and refluxed for 2 hours;

[0026] (3) Filter the system after the reflux extraction in step (2) while it is hot at a temperature of 85-90° C., and cool the obtained filtrate. During the cooling process, solid substances are precipitated. After the filtrate is cooled to 2° C., filter The precipitated solid matter was collected and dried at 65°C to obtain the indigo extract, which was stored away from light.

Embodiment 2

[0028] (1) Wash, dry, and pulverize the cyanide grass to 35 meshes to obtain the cyanoid grass pulverization, and then add the cyandicyst grass pulverization to a pH value of 7, and a volume percentage concentration of 85% (V 乙醇 :V 水 ) in an aqueous ethanol solution to obtain an extraction system,

[0029] Wherein, the pH value of the aqueous ethanol solution is regulated by sodium carbonate, and the mass ratio of the edulis edulis and the aqueous ethanol solution is 1: 25;

[0030] (2) Under stirring, the extraction system obtained in step (1) is heated up, and refluxed for 2 hours;

[0031] (3) Filter the system after the reflux extraction in step (2) while it is hot at a temperature of 85-90° C., and cool the obtained filtrate. During the cooling process, solid substances are precipitated. After the filtrate is cooled to 2° C., filter The precipitated solid matter was collected and dried at 70°C to obtain the indigo extract, which was stored away from light.

Embodiment 3

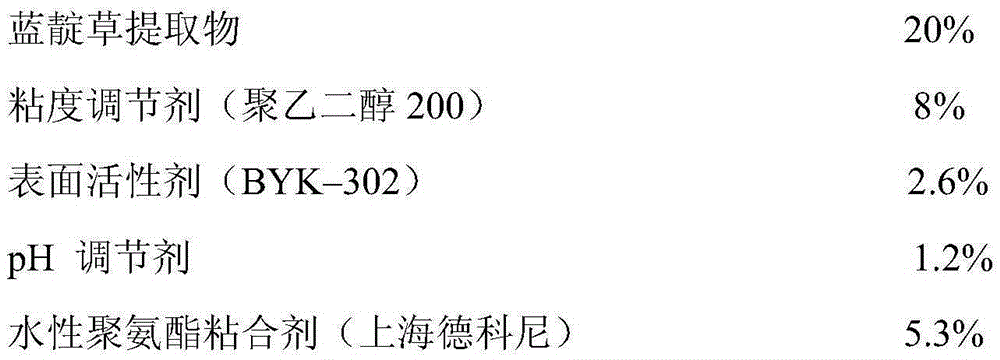

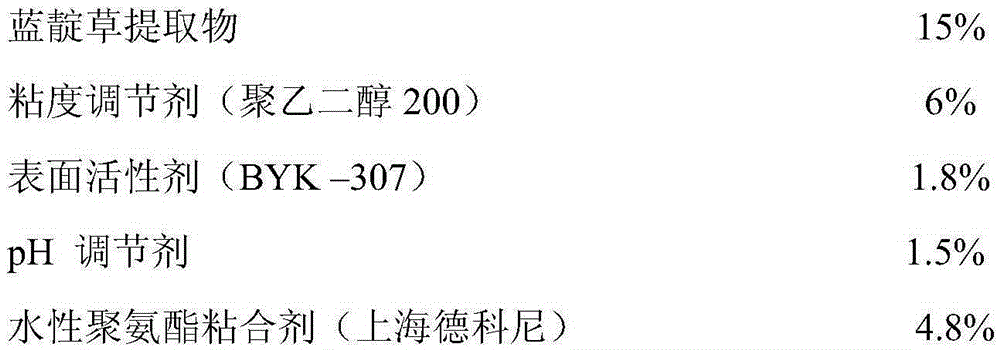

[0033] Based on the indigo extract prepared in Example 1, the inkjet printing paint is prepared:

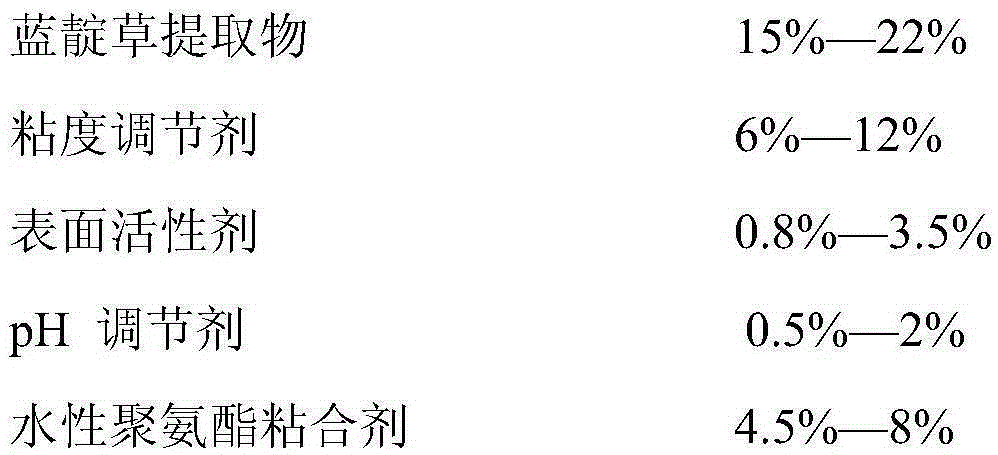

[0034] by weight percentage

[0035]

[0036] The rest is a mixed solvent of glycerin and water, wherein the volume ratio of glycerin and water is 1:1

[0037] Add indigo grass extract, viscosity regulator, surfactant, pH regulator, and water-based polyurethane adhesive to a mixed solvent of glycerin and water, stir evenly at room temperature, and pass the resulting mixture through pore diameters of 0.45 μm and 0.22 μm in sequence. μm membrane to obtain the final inkjet printing paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com