A kind of ZNO photoanode containing selenium and its preparation method and application

A photoanode and photoelectrochemical technology is applied in the field of selenium-containing ZnO photoanode and its preparation. Simple preparation steps, easy to deposit uniformly in large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

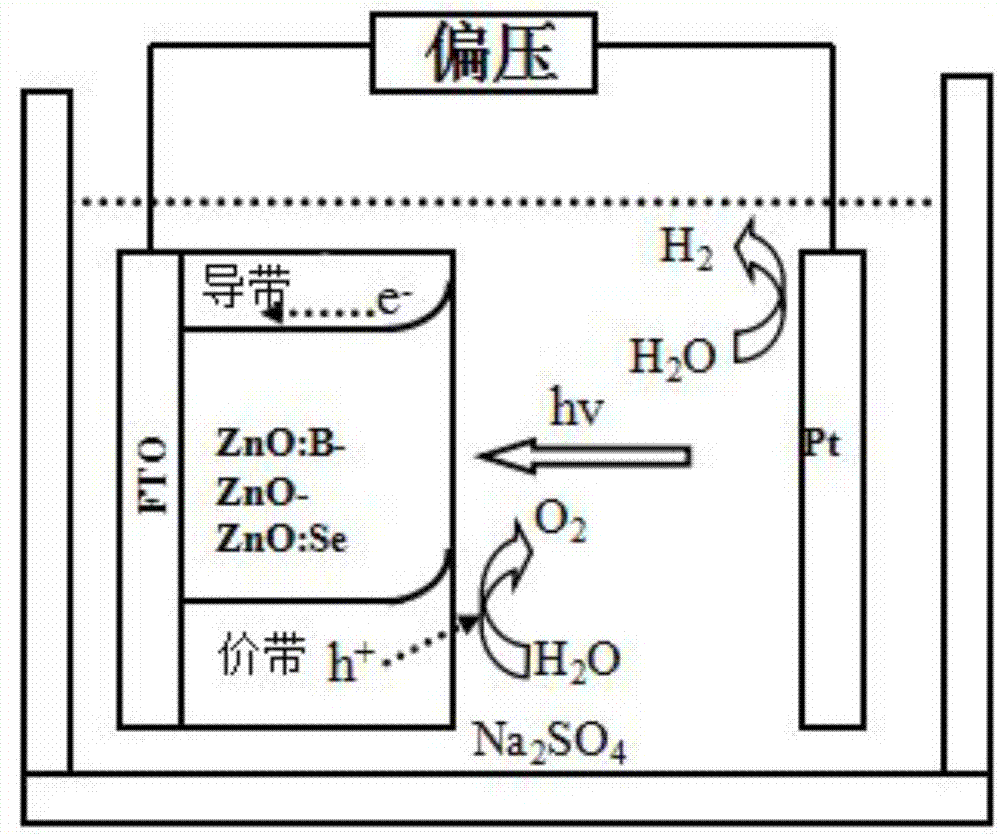

[0020] A selenium-containing ZnO photoanode is composed of a textured FTO substrate and a ZnO:B thin film, a ZnO thin film and a ZnO:Se thin film deposited sequentially on the textured FTO substrate surface, the thickness of the FTO substrate is 600nm, and the ZnO: Thicknesses of B thin film, ZnO thin film and ZnO:Se thin film are 2-3 μm, 1-2 μm and 1-2 μm, respectively. Its preparation method, the steps are as follows:

[0021] 1) Place the suede FTO substrate in an ethanol solution with a concentration of 99.7wt%, ultrasonically clean it for 30 min, and then use high-purity N 2 Blow dry, and use high-temperature adhesive tape to reserve an electron transport electrode that does not need to deposit ZnO on the FTO substrate;

[0022] 2) A single-chamber MOCVD deposition system is used to deposit ZnO film on the surface of the textured FTO substrate, in which the zinc source liquid is diethyl zinc (DEZn), the oxygen source liquid is water, and the dopant source gas is B 2 h ...

Embodiment 2

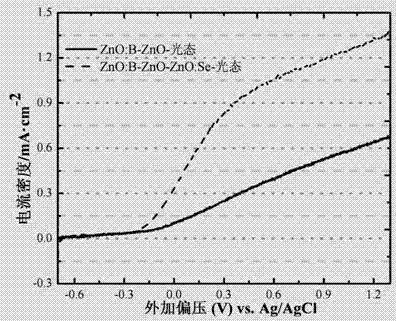

[0028] A selenium-containing ZnO photoanode is the same as in Example 1, and its preparation method is basically the same as in Example 1, except that: in step 2), the deposition temperature is 155° C., the diethyl zinc flow rate is 170 sccm, and the water vapor The flow rate is 100sccm, first, B 2 h 6 The flow rate is 6sccm, the deposition time is 45min, then, B 2 h 6 The flow rate is 0sccm, and the deposition time is 30min; the background vacuum in the thermal evaporation chamber in step 3) is 10 -3 Pa, the evaporation temperature is 450° C., and the selenization time is 35 min to prepare a ZnO:B-ZnO-ZnO:Se photoanode.

[0029] The linear sweep voltammetry curve of the prepared ZnO:B-ZnO-ZnO:Se photoanode is similar to that of Example 1.

Embodiment 3

[0031] A selenium-containing ZnO photoanode is the same as in Example 1, and its preparation method is basically the same as in Example 1, except that in step 2), the deposition temperature is 155° C., the diethylzinc flow rate is 180 sccm, and the water vapor The flow rate is 110sccm, first, B 2 h 6 The flow rate is 7sccm, the deposition time is 50min, then, B2 h 6 The flow rate is 0sccm, and the deposition time is 25min; the background vacuum in the thermal evaporation chamber in step 3) is 10 -3 Pa, the evaporation temperature is 450° C., and the selenization time is 45 min to prepare a ZnO:B-ZnO-ZnO:Se photoanode.

[0032] The linear sweep voltammetry curve of the prepared ZnO:B-ZnO-ZnO:Se photoanode is similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com