Method for quickly and accurately determining reactive property of dissolving pulp

A reaction performance and accurate measurement technology, applied in the direction of measuring device, color/spectral characteristic measurement, material analysis through optical means, etc., can solve the problem of low accuracy, achieve high accuracy, simplify operation process, and objective and accurate results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

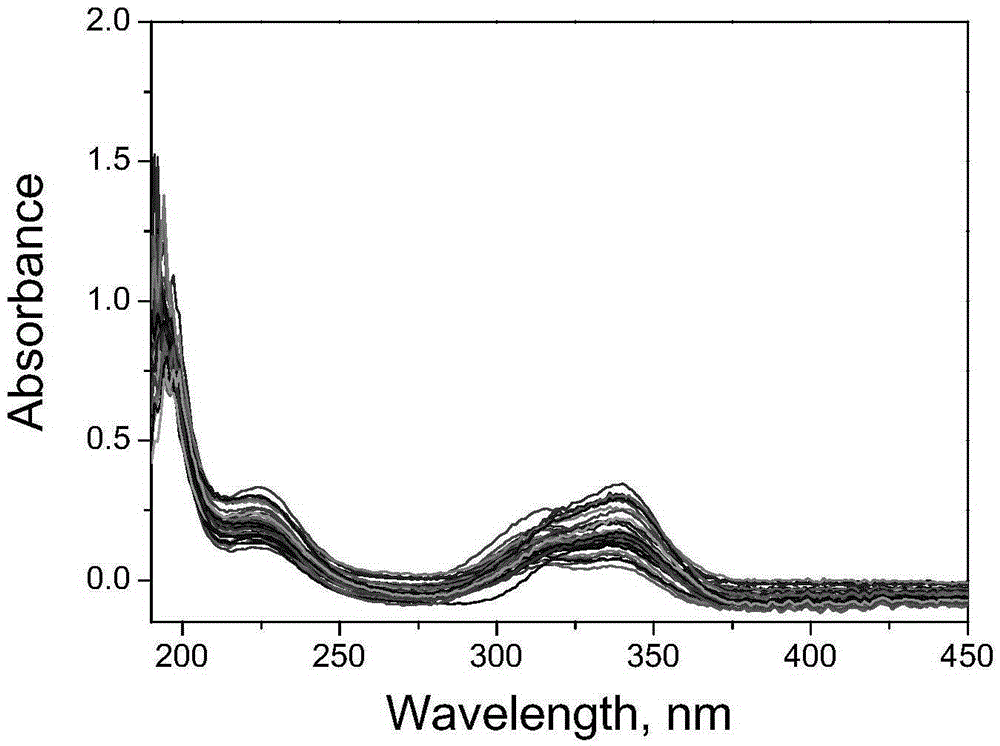

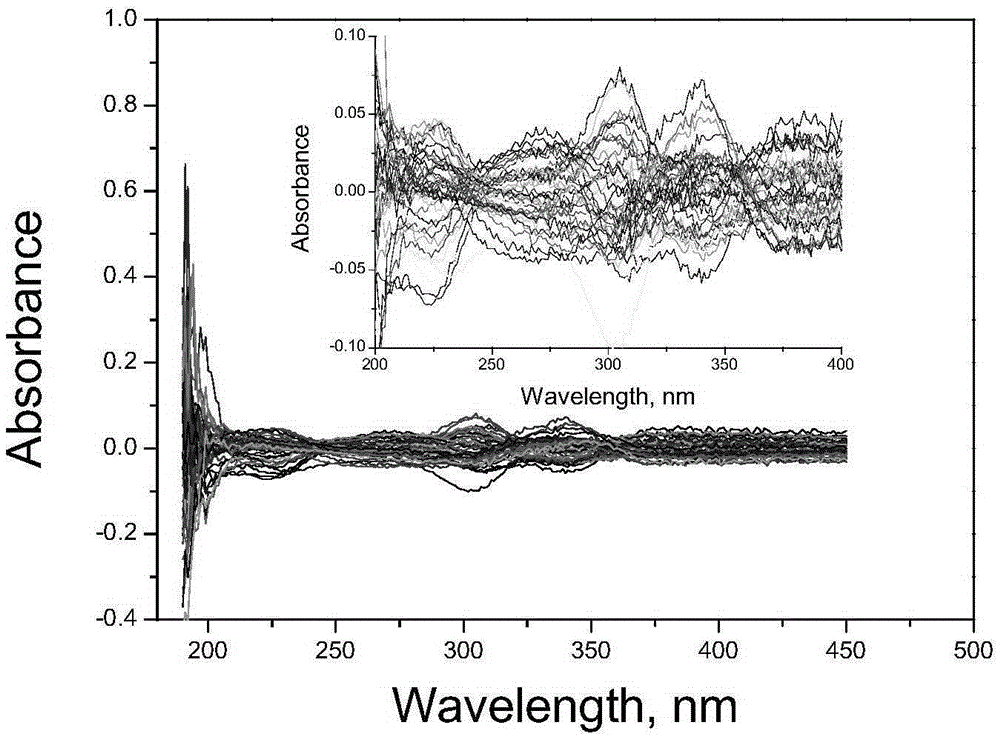

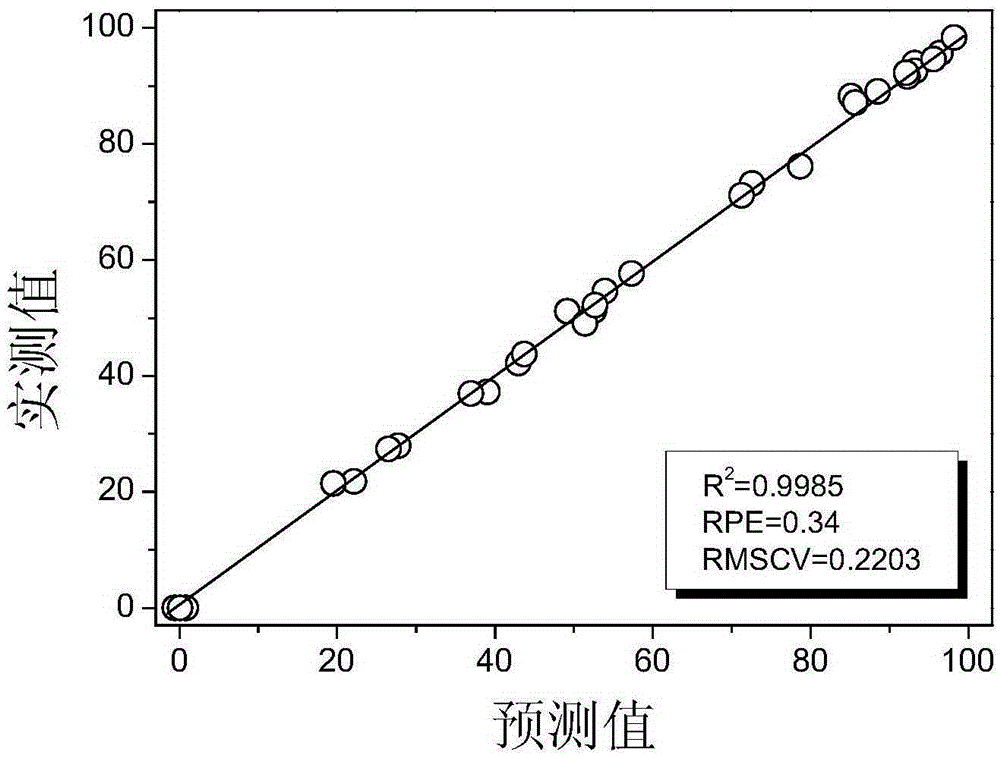

[0032] Such as Figures 1 to 4 shown.

[0033] (1) Sample alkalization and yellowing pretreatment:

[0034] Accurately weigh 0.50±0.01g (accurate to 1mg) of the sample to be tested and B-type 21×6mmmm stirrer B into a 150mL reagent bottle R with a lid that can be completely sealed, and then add 45mL of 11% w / w 30°C to the bottle Sodium hydroxide solution, after capping the bottle, place the reagent bottle on a temperature-controllable magnetic stirrer A, control the temperature at 30±1°C, and then stir at a stirring rate of 300rpm for 10min alkalization treatment. Then open the reagent bottle, add 1mL of carbon disulfide to it, and quickly cap the bottle, shake it up quickly, then place the reagent bottle on a magnetic stirrer with temperature control at 30±1°C for 3 hours of yellowing reaction, Stirring speed was maintained constant. After the reaction time is over, open the reagent bottle, add 50mL of distilled water to dilute, and then stir to obtain viscose; the sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com