Method of preparing vaccine through suspension culture of mammal cells and application of the method

A technology of cell suspension and cell culture, applied in biochemical equipment and methods, microorganisms, pharmaceutical formulations, etc., can solve problems such as high price, high cost of antigen production, difficulty in cell digestion and dissociation, and achieve production cost reduction, virus The effect of increasing content and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

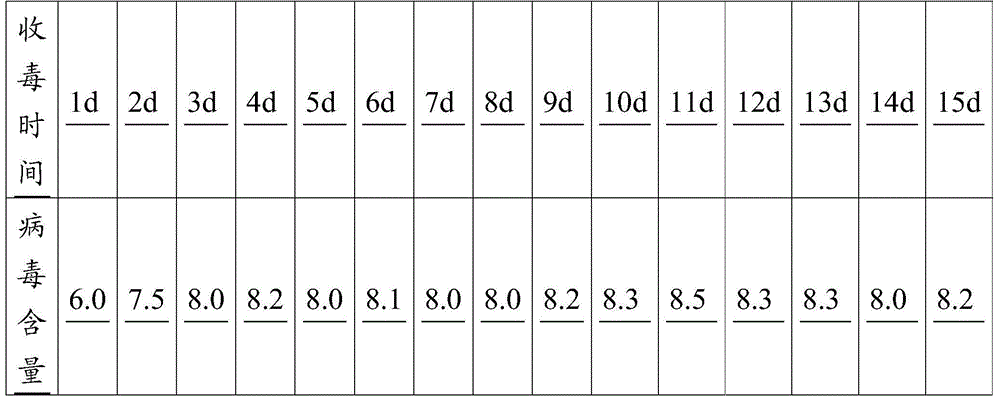

[0029] Embodiment 1, utilize bioreactor microencapsulation PK15 cell to produce PCV2 vaccine

[0030] (1) Cell preparation: After digestion of PK15 cells in the logarithmic growth phase, adjust the cell density to 2×10 6 cell / ml is used as coating material;

[0031] (2) Preparation of capsule material solution: add sodium alginate into ultrapure water according to the final concentration ratio of 15g / L, stir evenly, sterilize at 115°C for 30min, and set aside;

[0032] (3) Preparation of aqueous phase mixture: according to light CaCO 3 and ultrapure water 0.3 parts: 2 parts mass volume ratio (g / ml) after stirring evenly, after sterilizing at 115°C for 30 minutes, take 2 parts (ml), add 20 parts of sterile calcium alginate solution prepared in step (2) (ml), after mixing evenly, add 22 parts (ml) of the PK15 cell seed solution prepared in step (1), so that the final concentration of PK15 cells is 1×10 6 cell / ml, stir well and use as water phase;

[0033](4) Preparation of t...

Embodiment 2

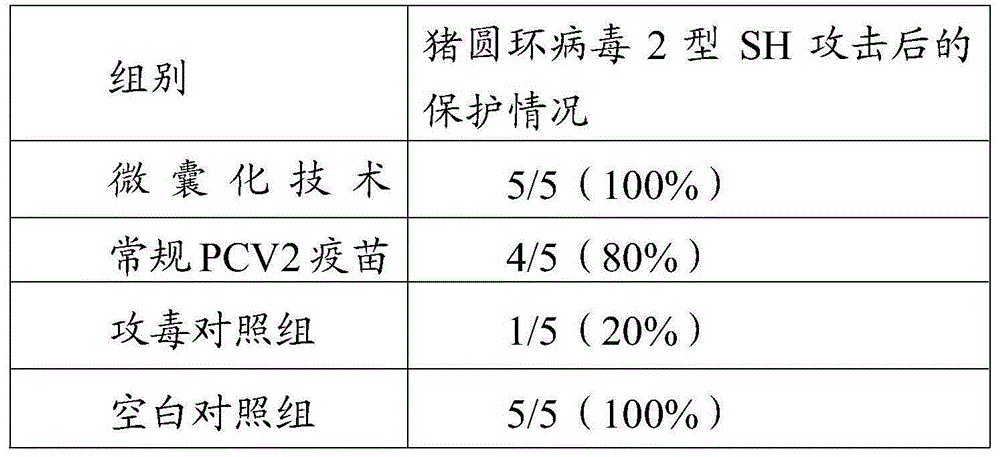

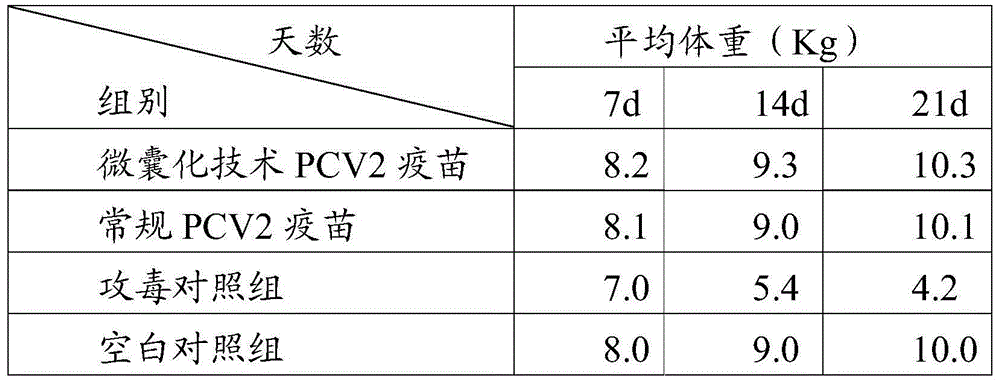

[0046] Example 2, Evaluation of the immune effect of PCV2 vaccine produced by microencapsulated PK15 cells in a bioreactor

[0047] Using the self-made PCV2 inactivated vaccine in Example 1 of the present invention, the immunization procedure is as follows: firstly, 7-day-old piglets are immunized for the first time, and 21 days later, the piglets are immunized for the second time. At the same time of immunization, the porcine PCV2 vaccine that has been marketed was immunized in the same way to evaluate the difference in immune effect between the PCV2 inactivated vaccine prepared by microencapsulation technology and the marketed vaccine.

[0048] 1. Materials

[0049] PCV-2 single-component vaccine, prepared according to Embodiment 1, wherein the content of each part of virus liquid ≥ 1 × 10 6.5 TCID 50 .

[0050] Porcine circovirus type 2 inactivated vaccine, Pulaike Bioengineering Co., Ltd., batch number 20130802.

[0051] 2. Test method

[0052] 20 double-negative pigl...

Embodiment 3

[0059] Embodiment 3, utilize bioreactor microencapsulation ST cell to produce classical swine fever virus vaccine

[0060] (1) Cell preparation: After digestion of ST cells in the logarithmic growth phase, adjust the cell density to 2×10 6 cell / ml is used as coating material;

[0061] (2) Preparation of capsule material solution: add sodium alginate into ultrapure water according to the final concentration ratio of 15g / L, stir evenly, sterilize at 115°C for 30min, and set aside;

[0062] (3) Preparation of aqueous phase mixture: according to light CaCO 3 and 0.3 parts of ultrapure water: 2 parts of weight-volume ratio (g / ml), after stirring evenly, after sterilizing at 115°C for 30 minutes, take 2 parts (ml), and add 20 parts of sterile calcium alginate solution prepared in step (2) (ml), after mixing evenly, add 22 parts (ml) of ST cell seed solution prepared in step (1), so that the final concentration of ST cells is 1×10 6 cell / ml, stir well and use as water phase;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com