TIP TIG welding method of LNG storage tanks

A welding method and storage tank technology, applied to welding equipment, arc welding equipment, household containers, etc., to achieve the effects of simple groove processing, small deformation, and concentrated arc energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

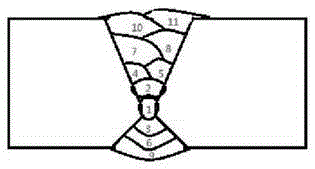

[0025] Please refer to figure 1 Shown, the present invention discloses LNG storage tank TIPTIG welding method, it comprises the following steps:

[0026] Step 1: Install a tungsten electrode with a diameter of 3.2mm for the welding equipment, the grinding angle of the tip of the tungsten electrode is 40°~50°, and the diameter of the tip of the tungsten electrode is 0.8mm.

[0027] Step 2: Select the welded joint of 9% NI steel plate with the wall plate thickness of the LNG inner tank of 17~22mm, the groove form adopts X-shaped welding groove, the minimum gap at the root of the workpiece is 2.0~2.4mm, and the groove angle is 60°, Blunt edge 1.0~1.5mm. Grind to remove attachments within 25mm on both sides of the weld groove to prevent oil, water, and rust pollution.

[0028] Step 3: The TIPTIG welding machine adopts DC positive connection, connects the positive pole of the welding power supply and the hot wire power supply to the welding base material, connects the negative p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com