Laminated body, conductive laminated body, and touch panel

A laminated body, transparent conductive layer technology, applied in the direction of layered products, electronic equipment, electrical digital data processing, etc., can solve the problem of liquid adhesives or liquid adhesives that are difficult to spread, wettability decline, water contact angle increase etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

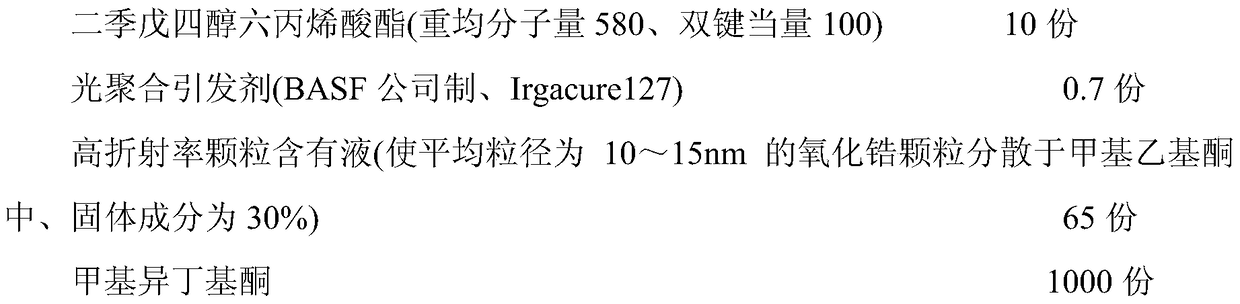

[0212] On one side (on the primer layer) of a biaxially stretched polyester film (manufactured by Toyobo Co., Ltd., A4300; with primer) with a thickness of 100 μm, a hard coating composition of the following formulation was used and dried according to The thickness of the coating is 2.0μm to form a hard coat layer.

[0213] Next, the high refractive index layer composition and the low refractive index layer composition of the following formulations were used to sequentially form a high refractive index layer (thickness 50 nm, refractive index 1.68) on the hard coat layer of the biaxially stretched polyester film And a low refractive index layer (thickness 30nm, refractive index 1.48).

[0214] It should be noted that the drying conditions of the optical function layer composed of the hard coat layer, the high refractive index layer, and the low refractive index layer are all 70° C. for 60 seconds. In addition, after the coating film of the composition for the hard coat layer, the ...

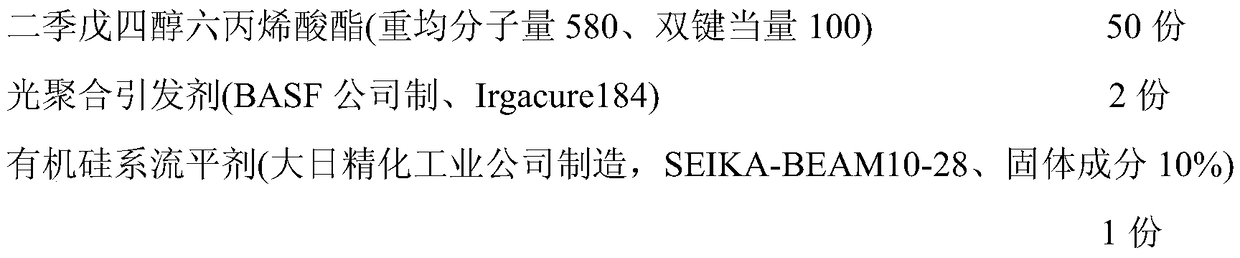

Embodiment 2

[0229] The composition 1 for the low contact angle layer of Example 1 was changed to the composition 2 for the low contact angle layer of the following formulation, and the composition 2 for the low contact angle layer was applied so that the thickness after drying was 2.0 μm After the coating film is formed, it is dried at 70°C for 60 seconds and irradiated with ultraviolet rays (150mJ / cm 2 ), except that the low contact angle layer was formed, a laminate was obtained in the same manner as in Example 1.

[0230]

[0231] Acrylic polymer solution (weight average molecular weight 160,000, double bond equivalent 1,000, solid content 25%) 16 parts

[0232] Dipentaerythritol hexaacrylate (weight average molecular weight 580, double bond equivalent of 100) 4 parts

[0233] Photopolymerization initiator (manufactured by BASF, Irgacure127) 0.8 parts

[0234] 30 parts of methyl isobutyl ketone

Embodiment 3

[0236] After forming an optical functional layer in the same manner as in Example 1, the composition for hard coating was applied to the other side of the biaxially stretched polyester film, and the coating film was formed so that the thickness after drying was 2.0 μm , Drying the coating film and irradiating ultraviolet rays to form a hard coat layer (refractive index 1.52). It should be noted that the drying conditions of the coating film are 70°C, 60 seconds, and the ultraviolet radiation dose is set to 150mJ / cm 2 . Next, using the composition 1 for a low contact angle layer, a low contact angle layer was formed on the hard coat layer formed on the other side of the biaxially stretched polyester film so as to have a thickness of 20 nm. The coating film formed by applying the composition 1 for the low contact angle layer was dried under the conditions of 70° C. and 60 seconds to obtain a laminate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com