Graphene material classification method

A grading method, graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as easy blockage of pores, ineffective grading effect, and increased steps for removing impurities, so as to prevent solvent volatilization and effectively Good for separation and rapid grading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of classification method of graphene material, comprises the following steps:

[0046] (1) Get graphene oxide material, add solvent, after stirring for 1h (100r / min), obtain graphene material mixed solution;

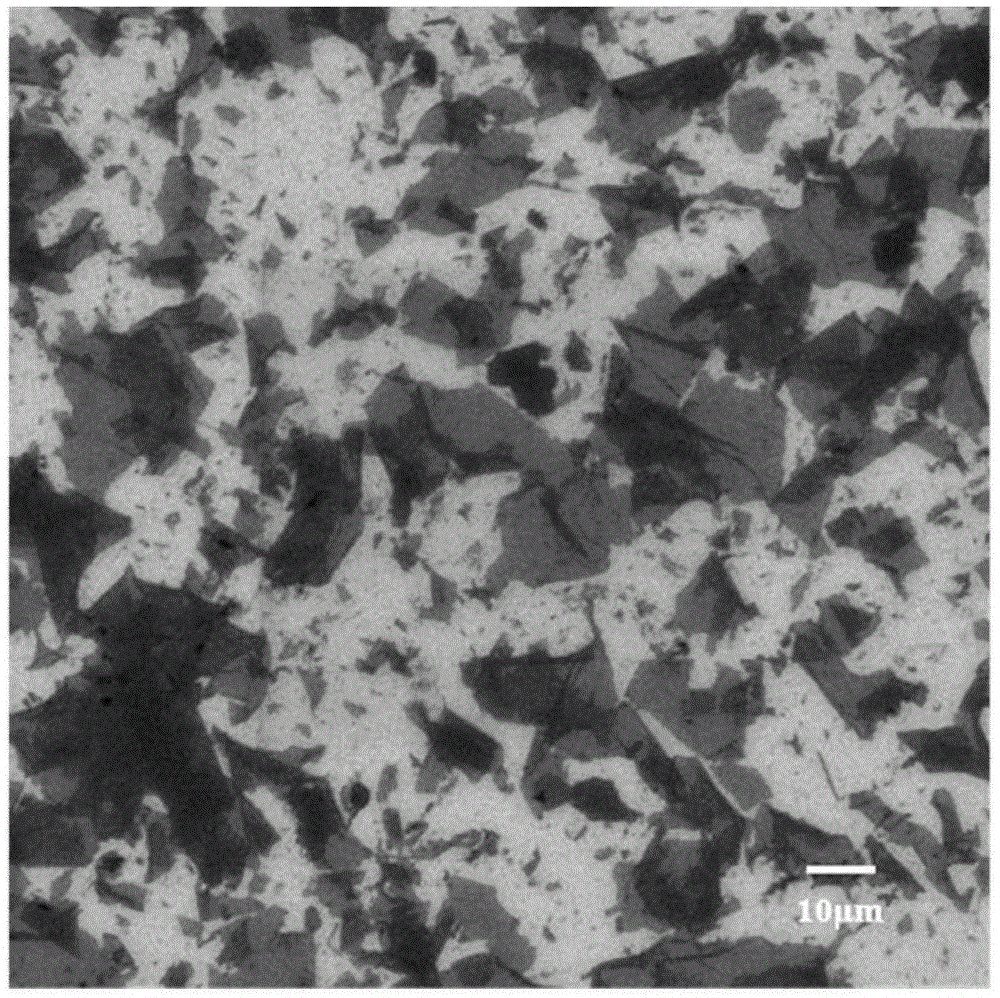

[0047] (2) add solvent to the graphene material mixed solution, after stirring for 0.5h (500r / min), obtain the graphene material dispersion liquid A that concentration is 20mg / mL, its scanning electron microscope picture is as follows figure 1 As shown, the size of the graphene material dispersion A is mixed;

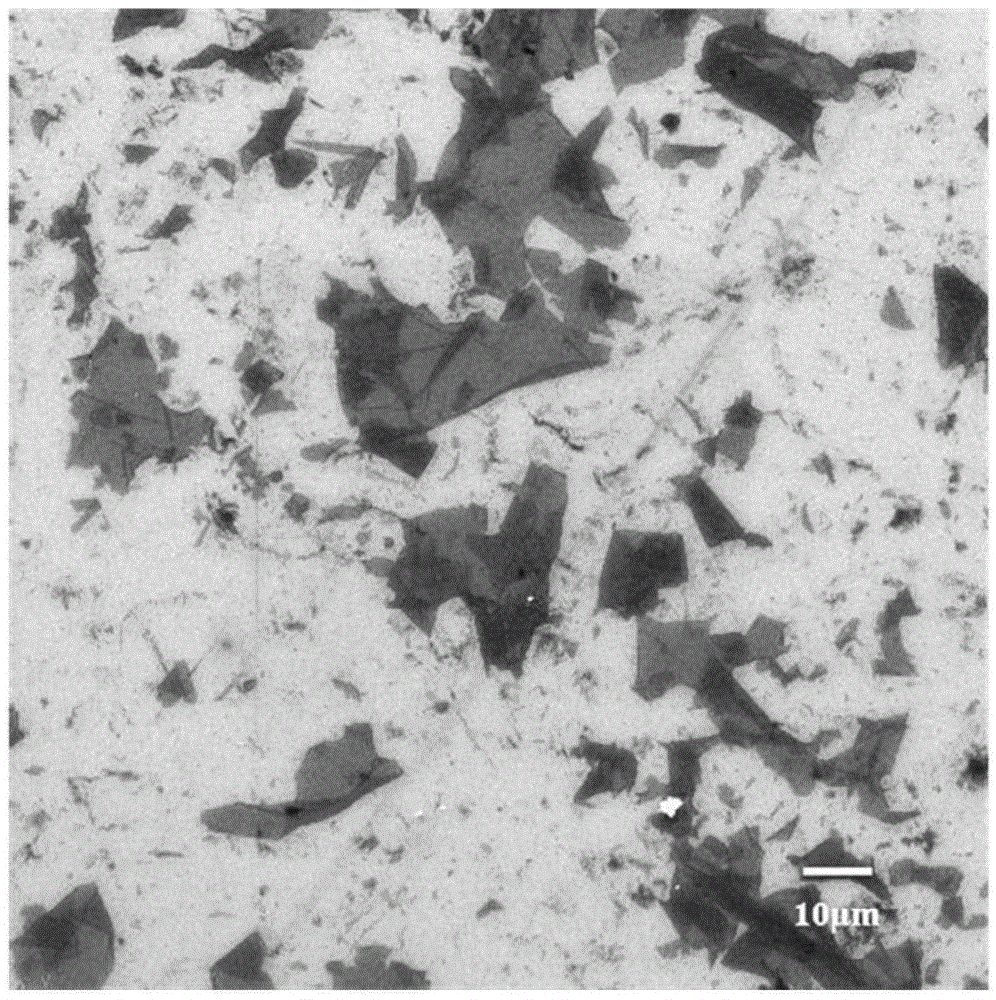

[0048] (3) Under the condition of 5 DEG C, the graphene material dispersion liquid A is subjected to the first-stage centrifugal classification treatment, the number of times of centrifugal classification of the first-stage centrifugal classification treatment is once, each time is 1min, and the rotating speed is 12000rpm / min, obtaining Precipitation B, the scanning electron microscope picture of precipitation B is as follows figure 2 As shown, it...

Embodiment 2

[0054] A kind of classification method of graphene material, comprises the following steps:

[0055] (1) Get graphene oxide material, add solvent, after stirring for 0.5h (500r / min), obtain graphene material mixed solution;

[0056] (2) add solvent to the graphene material mixed solution, after stirring for 0.7h (300r / min), obtain the graphene material dispersion liquid A that concentration is 1mg / mL, its scanning electron microscope picture is as follows Figure 5 As shown, the size of the graphene material dispersion A is mixed;

[0057] (3) Under the condition of 0°C, the graphene material dispersion A is subjected to the first-stage centrifugal classification treatment, the number of centrifugation of the first-stage centrifugal classification treatment is twice, each time is 20min, and the rotating speed is 8000rpm / min , to obtain precipitation B, the scanning electron microscope picture of precipitation B is as follows Figure 6 As shown, it can be seen that the precip...

Embodiment 3

[0063] A kind of classification method of graphene material, comprises the following steps:

[0064] (1) Take the reduced graphene oxide material, add a solvent, and stir for 0.7h (300r / min) to obtain the graphene material mixture;

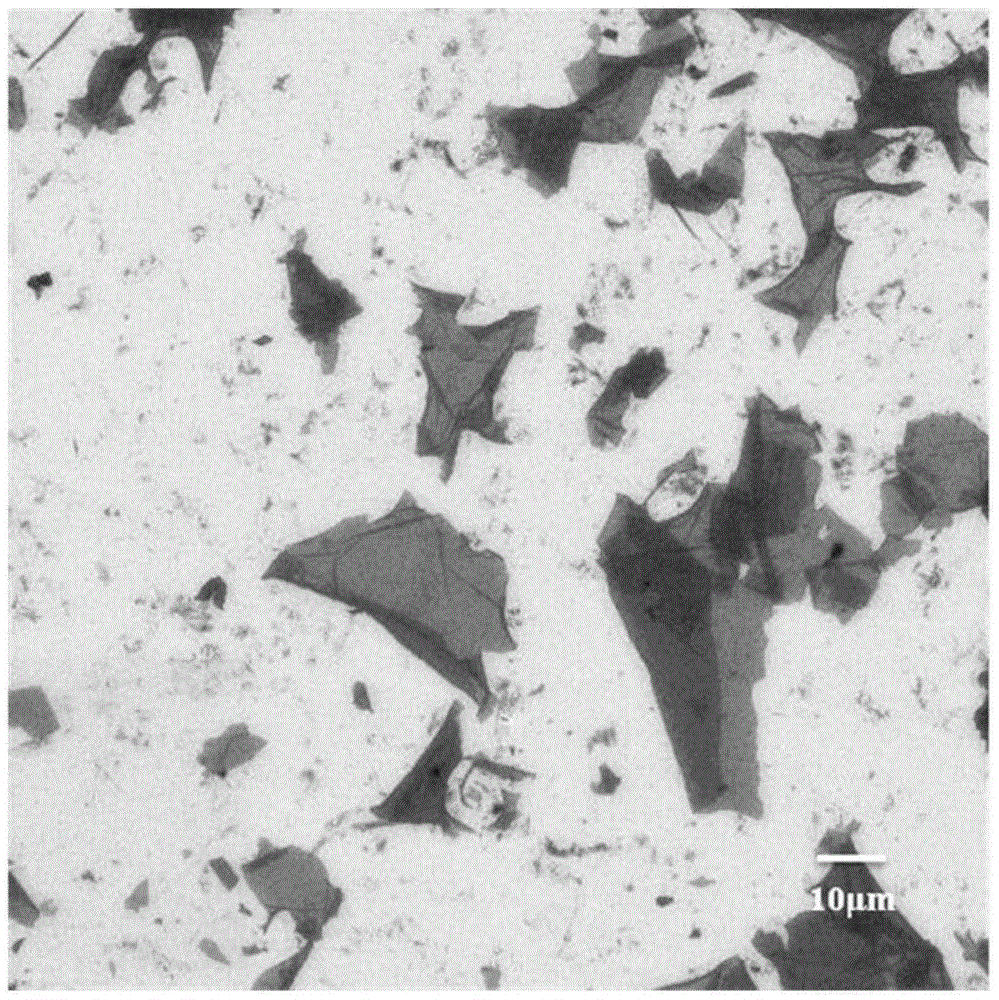

[0065] (2) add solvent in the graphene material mixed solution, obtain concentration after stirring 1h (100r / min) be the graphene material dispersion A of 10mg / mL, its scanning electron microscope picture is as follows Figure 9 As shown, the size of the graphene material dispersion A is mixed;

[0066] (3) Under the condition of 3°C, the graphene material dispersion A is subjected to the first-stage centrifugal classification treatment, the number of centrifugation of the first-stage centrifugal classification treatment is twice, each time is 10min, and the rotating speed is 10000rpm / min , to obtain precipitation B, the scanning electron microscope picture of precipitation B is as follows Figure 10 As shown, it can be seen that the precipitate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com