Cefoxitin sodium, preparation method and uses thereof

A technology of cefoxitin sodium and cefoxitin acid, applied in the field of its preparation and cefoxitin sodium, can solve the problems of cefoxitin sodium stability hidden danger, difficult to form stable crystal form, loss of washing and impurity removal effect, etc. , to achieve the effect of high solvent recovery efficiency, easy filtration and drying, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

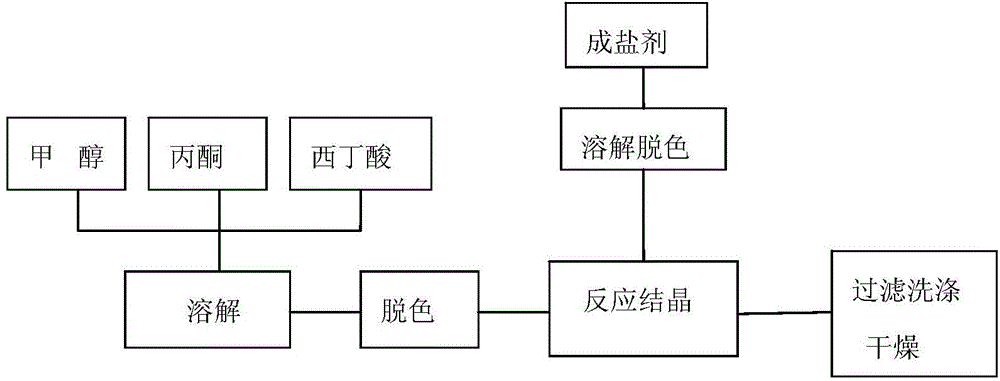

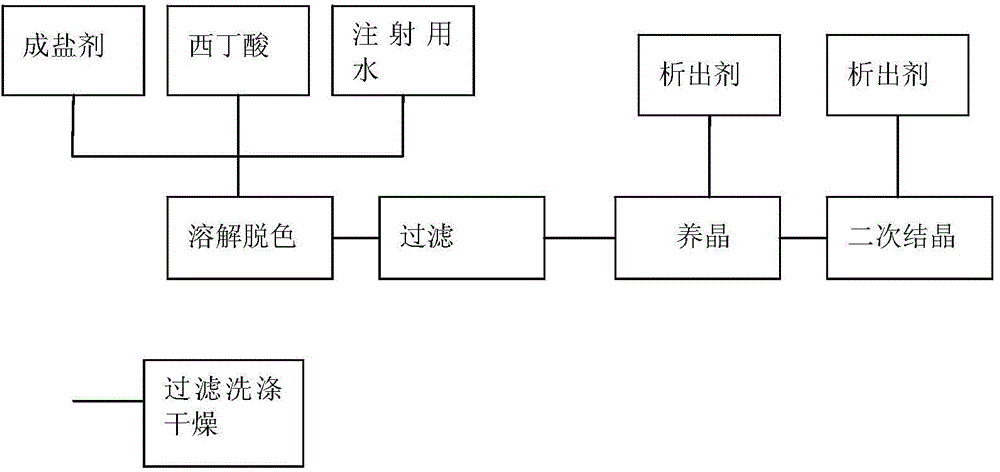

Method used

Image

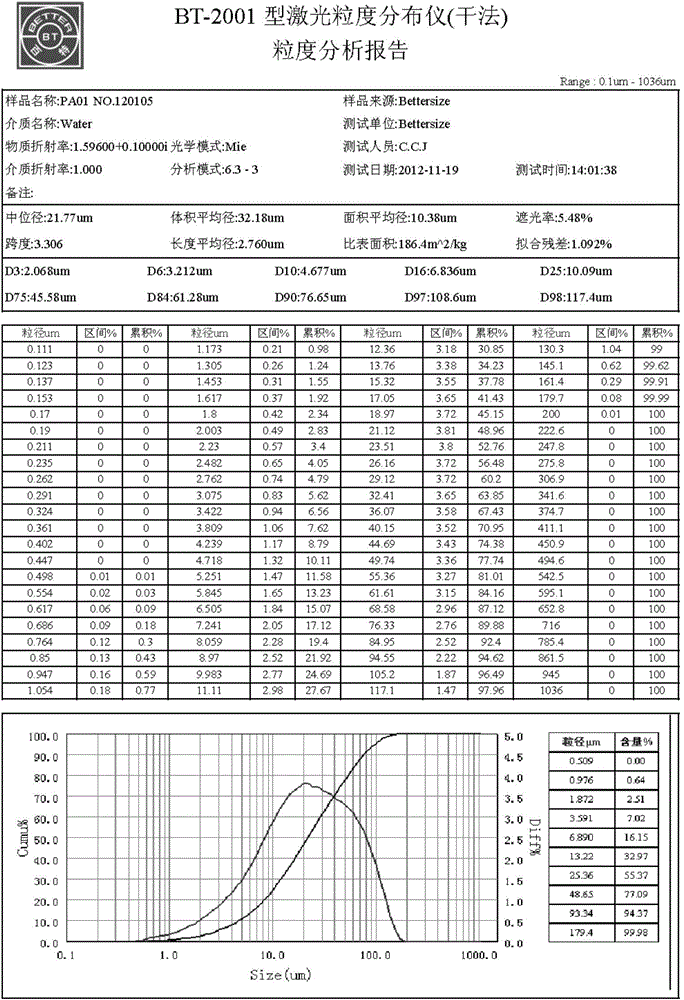

Examples

Embodiment 1

[0073] In a 1000ml three-necked flask, add 15g of sodium carbonate, 0.2g of hydrosulfite, add 150g of water for injection and stir to dissolve, add 100g of cefoxitin acid, stir and dissolve at 25°C, add 5g of activated carbon for decolorization for 20 minutes, filter, and add the filtrate to In a 2000ml three-neck flask, control the temperature at 20-25°C, add 700ml of ethanol, the solution is slightly cloudy, continue to stir until the solution becomes dark and cloudy, until a small amount of crystals are precipitated, the turbidity becomes shallow, and a large number of crystals are precipitated. Cool to 5 -10°C, add 1000ml of ethanol again after half an hour. Keep warm for half an hour, filter, wash with a small amount of ethanol, drain, wet weight 125g at 40°C, and dry in vacuum for 2 hours to obtain 94.5g dry product of cefoxitin sodium.

Embodiment 2

[0075] In a 1000ml three-necked flask, add 40g of sodium isooctanoate and 0.2g of sodium hydrosulfite, add 150ml of water for injection and stir to dissolve, add 100g of cefoxitin acid, stir and dissolve at 25°C, add 5g of activated carbon for decolorization for 20 minutes, filter, and add the filtrate to Put it into a 2000ml three-neck flask, control the temperature at 20-25°C, add 700ml of isopropanol, the solution is slightly cloudy, and continue to stir until the solution becomes dark and cloudy, until a small amount of crystals precipitate out, the turbidity becomes shallow, and a large number of crystals precipitate out. Cool to 5-10°C, add 1000ml isopropanol again half an hour later. Keep warm for half an hour, filter, wash with a small amount of isopropanol, and drain to dryness. The wet weight is 125g, and vacuum-dried at 40°C for 2 hours to obtain 97.6g of dry cefoxitin sodium.

Embodiment 3

[0077] In a 1000ml three-neck flask, add 50g of 80% sodium lactate, 0.2g of sodium lactate, add 150ml of water for injection and stir to dissolve, add 100g of cefoxitin acid, stir and dissolve at 25°C, add 5g of activated carbon for decolorization for 20 minutes, filter, and add the filtrate to 2000ml In the three-neck flask, control the temperature at 20-25°C, add 700ml of propanol, the solution is slightly cloudy, continue to stir until the solution becomes dark and cloudy, until a small amount of crystals are precipitated, the turbidity becomes shallow, and a large number of crystals are precipitated. Cool to 5 -10°C, after half an hour, 1000 ml of propanol was added again. Insulate for half an hour, filter, wash with a small amount of propanol, drain, wet weight 125g, and vacuum dry at 40°C for 2 hours to obtain 96.8g dry product of cefoxitin sodium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com