Quantum dot printing ink and preparation method thereof and quantum dot light-emitting diode

A technology of quantum dots and inks, which is applied in the field of quantum dot light-emitting diodes, quantum dot inks and their preparation, and can solve the problems of poor charge transmission efficiency of quantum dot light-emitting layer, affecting the performance of quantum dot light-emitting layer, low viscosity of quantum dot ink solution, etc. , to achieve the effect of improving QLED energy efficiency, improving effectiveness, and simple and controllable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] Correspondingly, the embodiment of the present invention also provides a preparation method of quantum dot ink, comprising the following steps:

[0089] S01. Weighing the formula components of the quantum dot ink;

[0090] S02. Dissolving the quantum dots, charge transport agent, dispersant and viscosity regulator in a solvent to form a blend;

[0091] S03. The blend is mixed.

[0092] Specifically, in the above step S01, the formulation of the quantum dot ink and its preferred components and contents have been stated above, and will not be repeated here to save space.

[0093] In the above step S02, the quantum dots, the charge transport agent, the dispersant and the viscosity modifier are dissolved in the solvent, and the method is not limited. As a preferred embodiment, the quantum dots are dissolved in the solvent first, and then other components are added. As another preferred embodiment, polar components such as the quantum dots, etc., can be dissolved in the m...

Embodiment 1

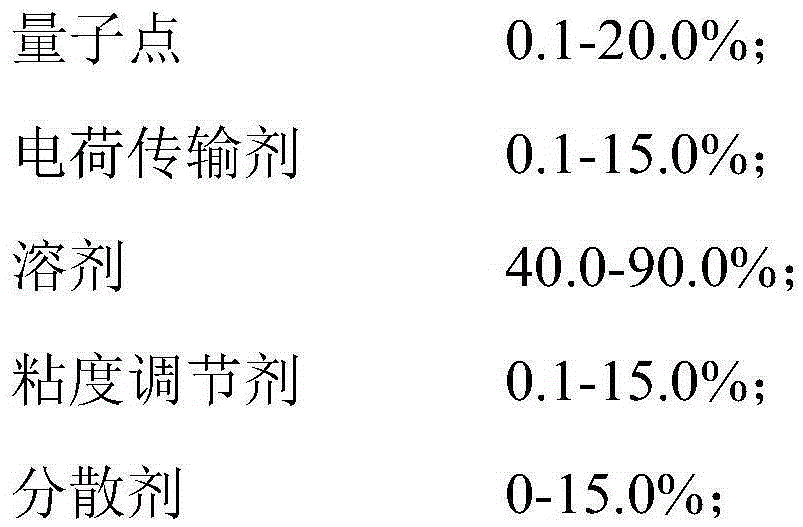

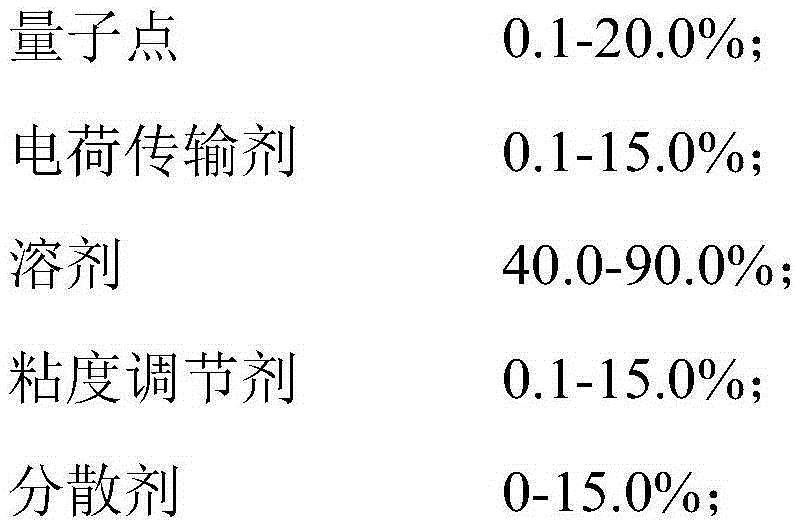

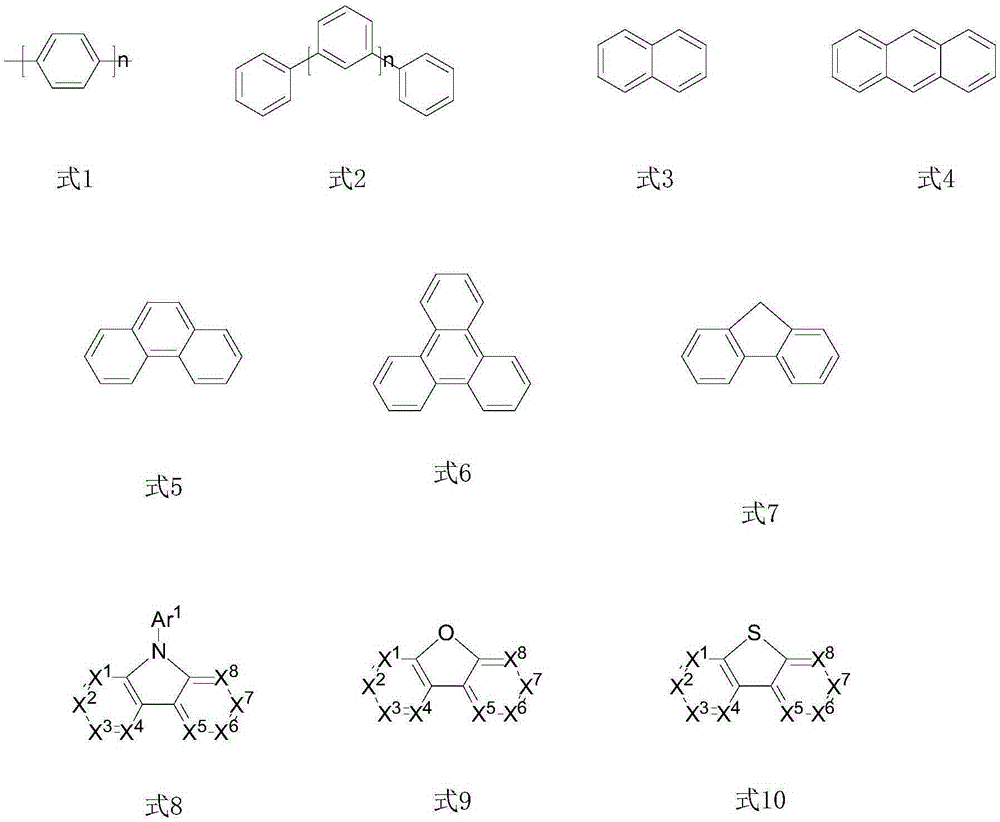

[0100] A quantum dot ink, based on the weight percentage of the quantum dot ink being 100%, comprising the components shown in the following table 1, Example 1, in weight percentage, wherein the quantum dot is oleylamine-stabilized Red CdSe / ZnS quantum dots, the positive charge transport agent is polyvinyl carbazole PVK, its structure is shown in the following structural formula 67, the negative charge transport agent is oxadiazole acrylate polymer, its structure is as the following structural formula 68, the main solvent is high-purity chlorobenzene, the co-solvent is dimethylformamide, the dispersant is betaine surfactant, and the viscosity regulator is glycerol.

[0101]

[0102] The preparation method of described quantum dot ink, comprises the following steps:

[0103] S11. Weighing the formula components of the above-mentioned quantum dot ink;

[0104] S12. under stirring condition, each component is added in the 500mL high-density polyethylene bottle containing solv...

Embodiment 2

[0108] Three kinds of quantum dot inks, based on the weight percentage of the quantum dot ink as 100%, comprise the components of the weight percentage shown in Example 2 of Table 1 below, wherein the quantum dots are oleylamine stabilized quantum dots point, the positive charge transporting agent is triphenylamine methacrylate and a small amount of azobisisobutylcyanide and ditrimethylolpropane tetraacrylic acid, its structure is shown in the following structural formula 69, and the negative charge transporting agent is Polypyridine-alkoxyphenyl, its structure is shown in the following structural formula 70, the main solvent is high-purity toluene, the co-solvent is dimethyl sulfoxide, and the dispersant is ethoxylated fatty amine surface active agent, the viscosity regulator is propylene glycol n-propyl ether;

[0109] Wherein, the quantum dots in the first quantum dot ink are blue CdS / CdZnS quantum dots, the quantum dots in the second quantum dot ink are green CdZnSe / CdZnS ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com