Method for preparing brain polypeptide and brain small-molecule peptide by means of pig brain protein through enzymolysis

A technology of proteolysis and small molecular peptides, applied in the field of bioengineering, can solve the problems of high production safety and labor safety requirements, long production cycle, high production cost, etc., and achieve production and labor safety and reliability, short production cycle and easy control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

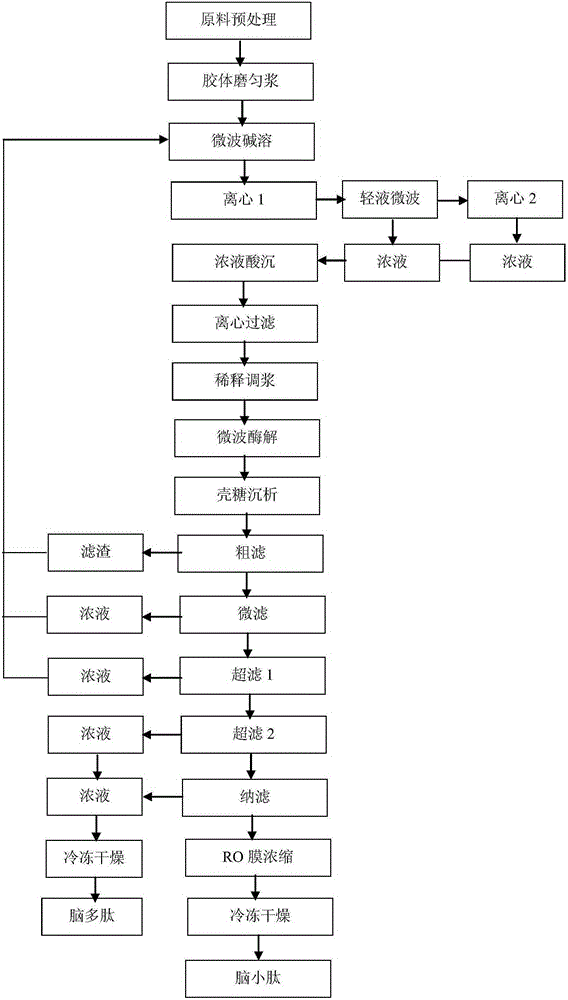

Method used

Image

Examples

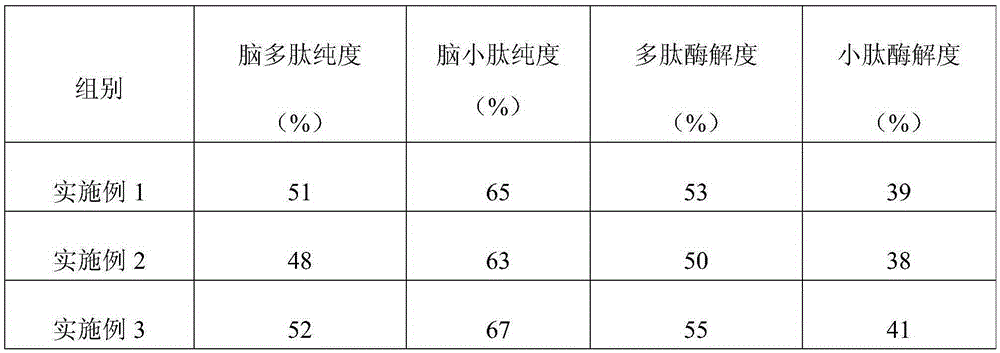

Embodiment 1

[0048] A method for preparing brain polypeptides and small brain molecule peptides by enzymatic hydrolysis of pig brain protein, comprising the following steps:

[0049] (1) Take out the fresh pig brain or the thawed frozen pig brain, wash the dirt, blood and impurities on the surface with pure water, and remove the fascia and blood vessels;

[0050] (2) After mixing the cleaned pig brain according to the ratio of raw materials and purified water at 1:0.8, use a colloid mill to grind the homogenate, adjust to the coarsest fineness during the initial grinding, and then adjust to the fineness after the tissue is basically broken. For finer fineness, grind and homogenize for 8 minutes / batch, then add pure water twice as much as the homogenate and continue homogenizing for 2 minutes, mix the homogenized brain plasma of each batch evenly, and adjust the pH value to 9.0 with NaOH solution ; The thickest fineness described is 80 orders; The thinner fineness described is 120 orders; ...

Embodiment 2

[0060] A method for preparing brain polypeptides and small brain molecule peptides by enzymatic hydrolysis of pig brain protein, comprising the following steps:

[0061] (1) Take out the fresh pig brain or the thawed frozen pig brain, wash the dirt, blood and impurities on the surface with pure water, and remove the fascia and blood vessels;

[0062] (2) After mixing the cleaned pig brain according to the ratio of raw materials and purified water at 1:1.0, use a colloid mill to grind the homogenate, adjust to the coarsest fineness during the initial grinding, and then adjust to the fineness after the tissue is basically broken. For finer fineness, grind and homogenize for 10 minutes / batch, then add pure water twice as much as the homogenate and continue homogenizing for 3 minutes, mix the homogenized brain plasma of each batch evenly, and adjust the pH value to 9.0 with NaOH solution ; The thickest fineness described is 80 orders; The thinner fineness described is 120 orders; ...

Embodiment 3

[0072] A method for preparing brain polypeptides and small brain molecule peptides by enzymatic hydrolysis of pig brain protein, comprising the following steps:

[0073] (1) Take out the fresh pig brain or the thawed frozen pig brain, wash the dirt, blood and impurities on the surface with pure water, and remove the fascia and blood vessels;

[0074] (2) After mixing the cleaned pig brain according to the ratio of raw materials and purified water at 1:0.9, use a colloid mill to grind the homogenate, adjust to the coarsest fineness during the initial grinding, and then adjust to the fineness after the tissue is basically broken. For finer fineness, grind and homogenize the cycle for 9 minutes / batch, then add pure water twice as much as the homogenate and continue homogenizing for 2.5 minutes, mix the homogenized brain plasma of each batch evenly, and adjust the pH value with NaOH solution to 9.0; the coarsest fineness mentioned is 80 mesh; the finer fineness described is 120 me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com