Making method for molybdenum oxide nano-fiber paper hydrogen sensor

A technology of nanofiber and molybdenum oxide, applied in the direction of material resistance, etc., to achieve high specific surface area, good recovery performance, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

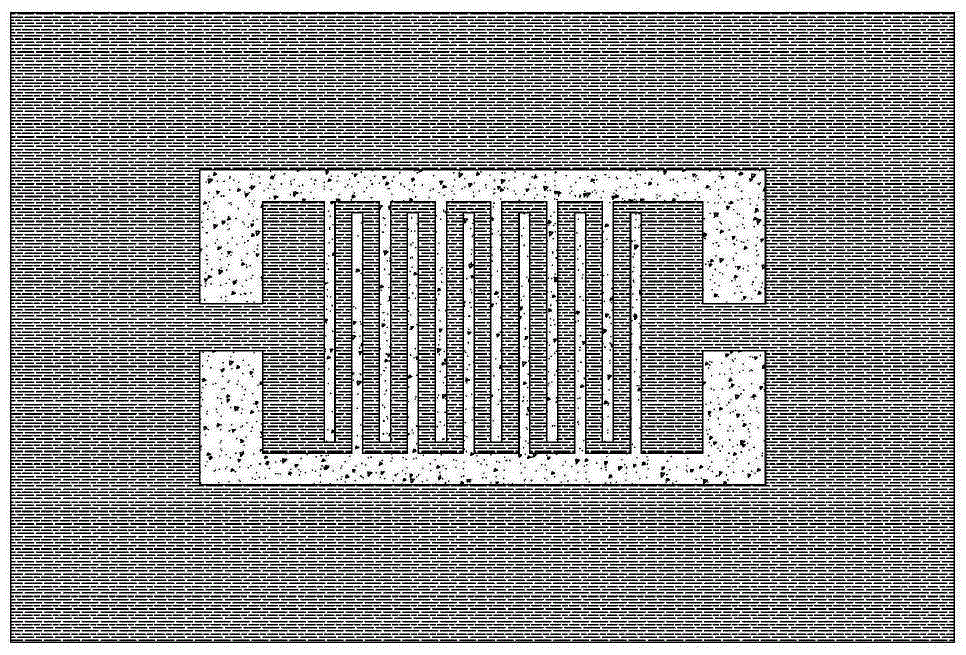

[0027] A method for preparing a molybdenum oxide nanofiber paper hydrogen sensor of the present invention is to sputter a metal Pt / Pd nanoparticle array on a molybdenum oxide nanofiber paper covered with a metal mask to form a conductive electrode method; the preparation method includes the following steps: step:

[0028] (1) Take the molybdenum oxide nanofiber paper of the set size;

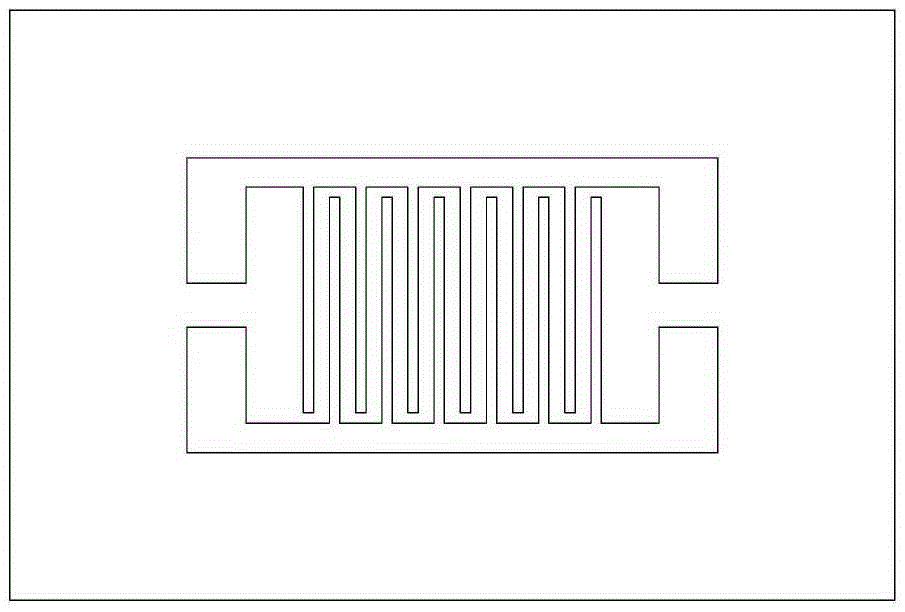

[0029] (2) Select a sputtering metal mask with a set size, and there are 12 pairs of interdigitated electrodes on the metal mask, and cover the metal mask on the molybdenum oxide nanofiber paper to form a substrate;

[0030] (3) metal Pt / Pd nanoparticle arrays are sputtered on the substrate to make a hydrogen sensor with conductive electrodes:

[0031] (4) After the sputtering is completed, the metal mask is removed, and the molybdenum oxide nanofiber paper after the sputtered Pt / Pd nanoparticle array is cut from the middle along the length direction to become two hydrogen sensitive elements wi...

Embodiment 1

[0035] 1. Select molybdenum oxide nanofiber paper with a size of 30mm×20mm.

[0036] 2. Select a metal mask with the same size as the molybdenum oxide nanofiber paper (such as figure 2 As shown), the metal mask plate has 4 large electrodes and 12 pairs of small electrodes. Adopting this structure is beneficial to subsequent testing and packaging.

[0037] 3. Cleaning of the mask: The selected metal mask is ultrasonically cleaned for 30 minutes with analytical acetone, pure ethanol and deionized water, and then baked in air at a temperature of 60°C for 20 minutes to obtain a clean and dry mask. Metal mask.

[0038] In this embodiment, the ultrasonic cleaner is a commercially available numerically controlled ultrasonic cleaner with a cleaning power of 40-100W.

[0039] 4. Using standard DC magnetron sputtering technology to prepare oxide film nanofiber paper hydrogen sensor, the steps are as follows:

[0040] (1) Place the sample: First, open the magnetron sputtering equipme...

Embodiment 2

[0048] 1. Select molybdenum oxide nanofiber paper with a size of 30mm×20mm.

[0049] 2. Select a metal mask with the same size as the molybdenum oxide nanofiber paper (such as figure 2 As shown), the metal mask plate has 4 large electrodes and 12 pairs of small electrodes. Adopting this structure is beneficial to subsequent testing and packaging.

[0050] 3. Cleaning of the mask: The selected metal mask is ultrasonically cleaned for 30 minutes with analytical acetone, pure ethanol and deionized water, and then baked in air at a temperature of 60°C for 20 minutes to obtain a clean and dry mask. Metal mask.

[0051] In this embodiment, the ultrasonic cleaner is a commercially available numerically controlled ultrasonic cleaner with a cleaning power of 40-100W.

[0052] 4. Using standard DC magnetron sputtering technology to prepare oxide film nanofiber paper hydrogen sensor, the steps are as follows:

[0053] (1) Place the sample: First, open the magnetron sputtering equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com