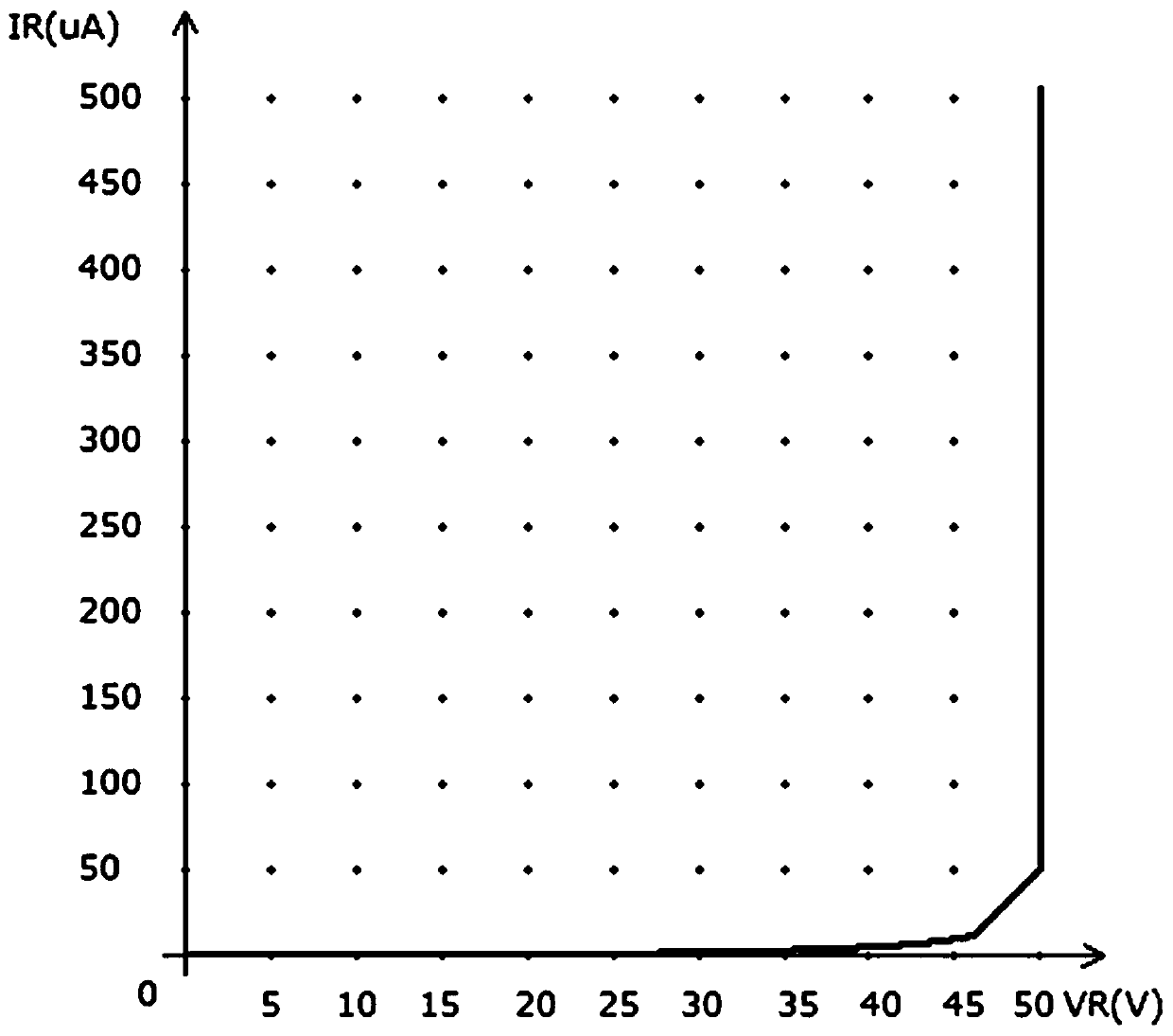

A Manufacturing Technology of 40v Schottky Diode with Reduced Secondary Breakdown Ratio

A Schottky diode, secondary breakdown technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc. The effect of increasing junction depth and uniformity and increasing impurity concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

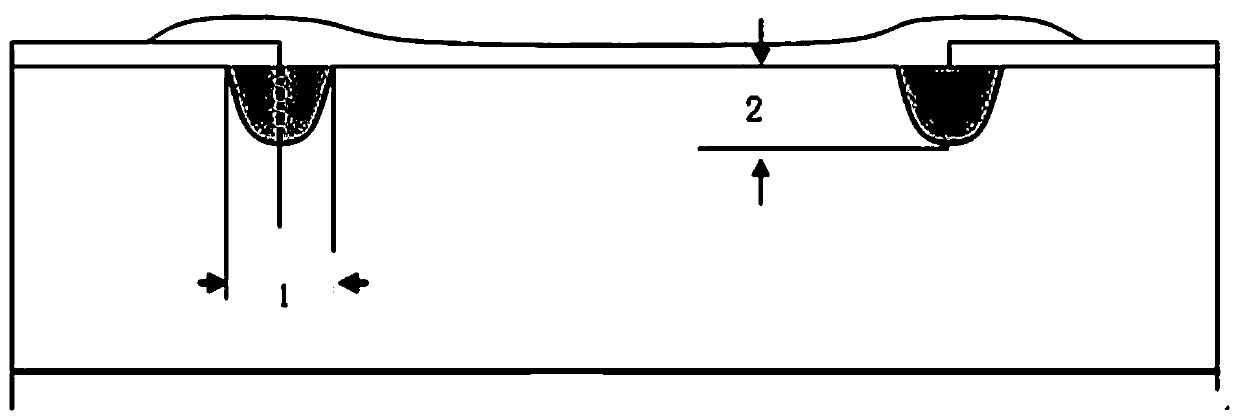

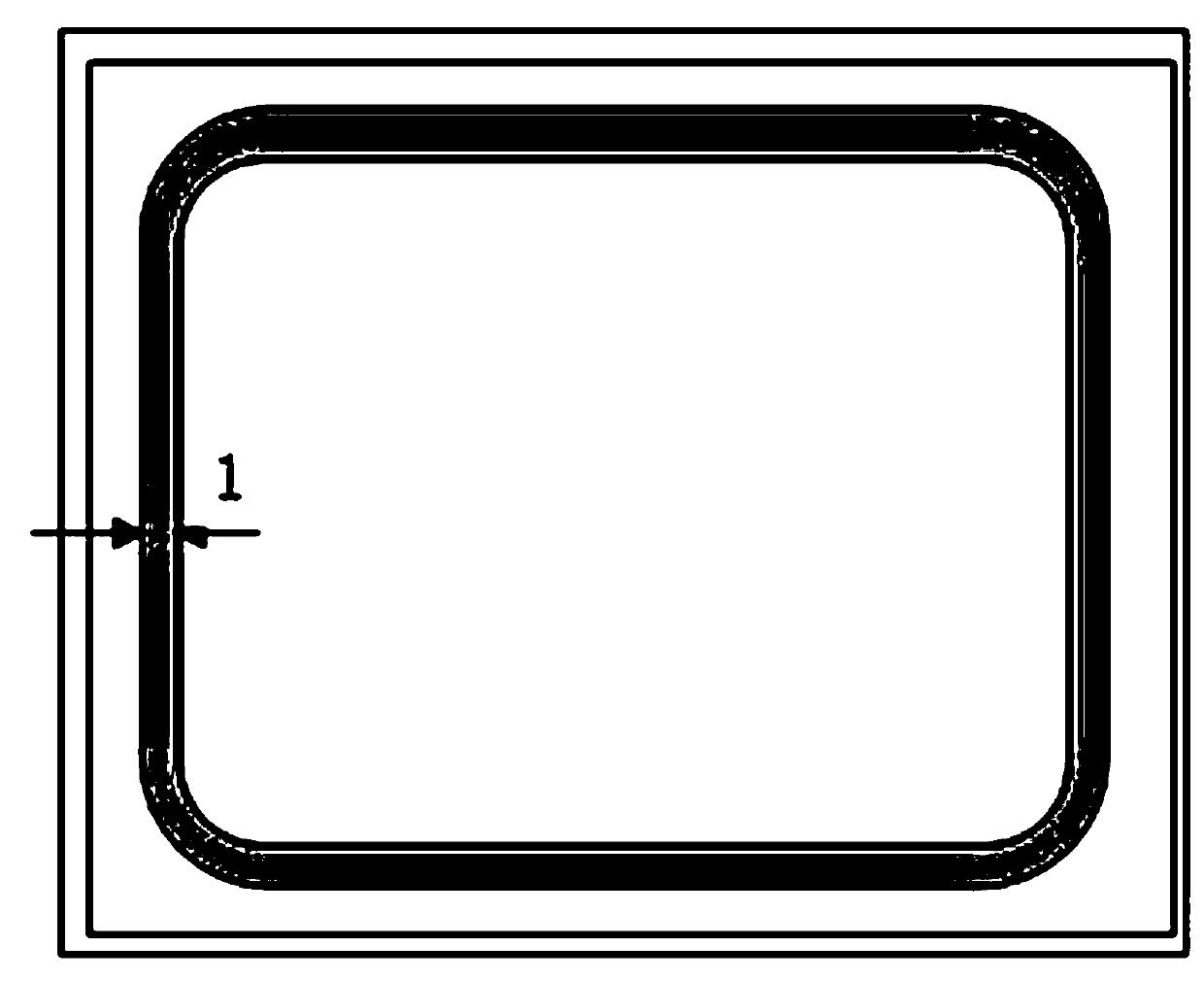

[0035] A 40V Schottky diode manufacturing process (only applied to 40V) that reduces the secondary breakdown ratio. The steps are:

[0036] a. Substrate silicon wafer cleaning: substrate silicon wafers are cleaned with NH 3 h 2 O:H 2 o 2 :H 2 O=1:1:5 cleaning solution and HCL:H 2 o 2 :H 2 O = 1:1:5 cleaning solution at 75°C for 10 minutes each, rinse the substrate wafers with water for 10 minutes, and dry them before use;

[0037] b. Initial oxidation: The substrate silicon wafer that has completed step a is subjected to the initial oxidation process. First, put the silicon wafer into a quartz boat, and then enter the boat into the quartz furnace tube. The boat speed is 20cm / s. After the boat enters, cover the grinding port. Nitrogen was introduced at 750°C, 6 liters per minute, for 30 minutes, the temperature was raised from 750°C to 950°C, and the temperature was kept at 950°C. Stop nitrogen and change to oxygen. After 10 minutes of oxygen, change to oxygen and hydrog...

Embodiment 2

[0059] A 40V Schottky diode manufacturing process (only applied to 40V) that reduces the secondary breakdown ratio. The steps are:

[0060] a. Substrate silicon wafer cleaning: substrate silicon wafers are cleaned with NH 3 h 2 O:H 2 o 2 :H 2 O=1:1:5 cleaning solution and HCL:H 2 o 2 :H 2 O = 1:1:5 cleaning solution at 70°C for 9 minutes each, rinse the substrate wafer with water for 9 minutes, and dry it for later use;

[0061] b. Initial oxidation: The substrate silicon wafer that has completed step a is subjected to the initial oxidation process. First, put the silicon wafer into a quartz boat, and then enter the boat into the quartz furnace tube. The boat speed is 19cm / s. After the boat enters, cover the grinding port. Nitrogen was fed at 747°C, 5 liters per minute, 29 minutes, the temperature rose from 747°C to 947°C, and the temperature was kept at 947°C. Stop nitrogen and change to oxygen. After 9 minutes of oxygen, change to oxygen and hydrogen for hydrogen Oxy...

Embodiment 3

[0083] A 40V Schottky diode manufacturing process (only applied to 40V) that reduces the secondary breakdown ratio. The steps are:

[0084] a. Substrate silicon wafer cleaning: substrate silicon wafers are cleaned with NH 3 h 2 O:H 2 o 2 :H 2 O=1:1:5 cleaning solution and HCL:H 2 o 2 :H 2 O = 1:1:5 cleaning solution at 80°C for 11 minutes each, rinse the substrate wafer with water for 1 minute, and dry it before use;

[0085] b. Initial oxidation: The substrate silicon wafer that has completed step a is subjected to the initial oxidation process. First, put the silicon wafer into a quartz boat, and then enter the boat into the quartz furnace tube. The boat speed is 21cm / s. After entering the boat, cover the grinding port. Nitrogen was fed at 753°C, 7 liters per minute, 31 minutes, the temperature rose from 753°C to 953°C, and the temperature was kept at 953°C. Stop nitrogen and change to oxygen. After 11 minutes of oxygen, change to oxygen and hydrogen for hydrogen Oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com