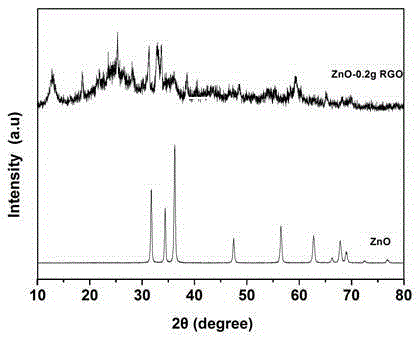

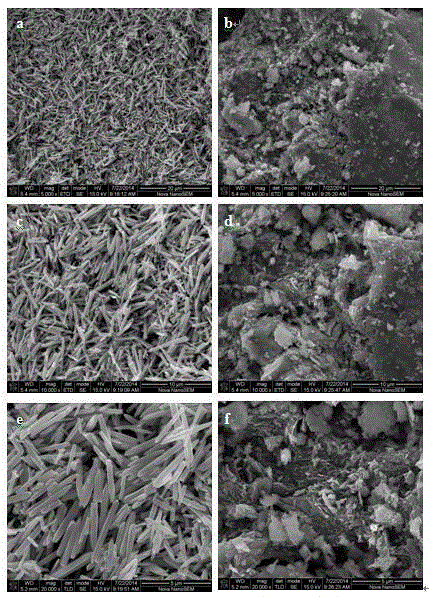

Preparing method and application of ZnO-Graphene lithium ion battery cathode material

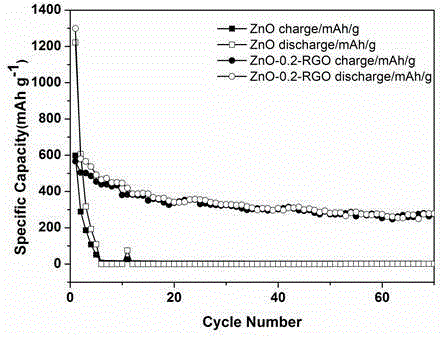

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of rapid attenuation, poor cycle performance, etc., and achieve the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Preparation of graphite:

[0049] 1) Place 20ml three -mouth bottle in an ice water bath, add 80ml concentrated sulfuric acid, 2g graphite, sodium 1g of nitrate, and stir for 1 hour.Under the condition of maintaining the temperature below 10 ° C, slowly add potassium permanganate to the bottle, stir for 1 hour, and revoke the water bath.Under the condition of maintaining the temperature below 20 ° C, slowly add 6g of potassium permanganate to the bottle, add it to 35 ° C after adding, and stir for 60 minutes;

[0050] 2) Slowly add 90ml distilled water to the bottle, heat up to 80 ° C, and stir for 30 minutes; add 7ml 30%hydrogen peroxide to the solution, distilled 55ml of distilled water, and place it for 12 hours;

[0051] 3) Use 3%dilute hydrochloric acid, rinse the product for the product, centrifugal 3 times, transfer to the 40 ° C oven for 30 minutes, remove it, place it in a dine, and dry at room temperature; get the product.

[0052] (2) ZNO's water heat metho...

Embodiment 2

[0057] (1) Preparation of graphite:

[0058] 1) Place 20ml three -mouth bottle in an ice water bath, add 80ml concentrated sulfuric acid, 2g graphite, sodium 1g of nitrate, and stir for 1 hour.Under the condition of maintaining the temperature below 10 ° C, slowly add potassium permanganate to the bottle, stir for 1 hour, and revoke the water bath.Under the condition of maintaining the temperature below 20 ° C, slowly add 6g of potassium permanganate to the bottle, add it to 35 ° C after adding, and stir for 60 minutes;

[0059] 2) Slowly add 90ml distilled water to the bottle, heat up to 80 ° C, and stir for 30 minutes; add 7ml 30%hydrogen peroxide to the solution, distilled 55ml of distilled water, and place it for 12 hours;

[0060] 3) Use 3%dilute hydrochloric acid, rinse the product for the product, centrifugal 3 times, transfer to the 40 ° C oven for 30 minutes, remove it, place it in a dine, and dry at room temperature; get the product.

[0061] (2) ZNO's water heat metho...

Embodiment 3

[0066] (1) Preparation of graphite:

[0067] 1) Place 20ml three -mouth bottle in an ice water bath, add 80ml concentrated sulfuric acid, 2g graphite, sodium 1g of nitrate, and stir for 1 hour.Under the condition of maintaining the temperature below 10 ° C, slowly add potassium permanganate to the bottle, stir for 1 hour, and revoke the water bath.Under the condition of maintaining the temperature below 20 ° C, slowly add 6g of potassium permanganate to the bottle, add it to 35 ° C after adding, and stir for 60 minutes;

[0068] 2) Slowly add 90ml distilled water to the bottle, heat up to 80 ° C, and stir for 30 minutes; add 7ml 30%hydrogen peroxide to the solution, distilled 55ml of distilled water, and place it for 12 hours;

[0069] 3) Use 3%dilute hydrochloric acid, rinse the product for the product, centrifugal 3 times, transfer to the 40 ° C oven for 30 minutes, remove it, place it in a dine, and dry at room temperature; get the product.

[0070] (2) ZNO's water heat method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com