DC/DC conversion circuit and power supply device

A conversion circuit and converter technology, applied in output power conversion devices, DC power input conversion to DC power output, electrical components, etc. , The effect of reducing voltage stress and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

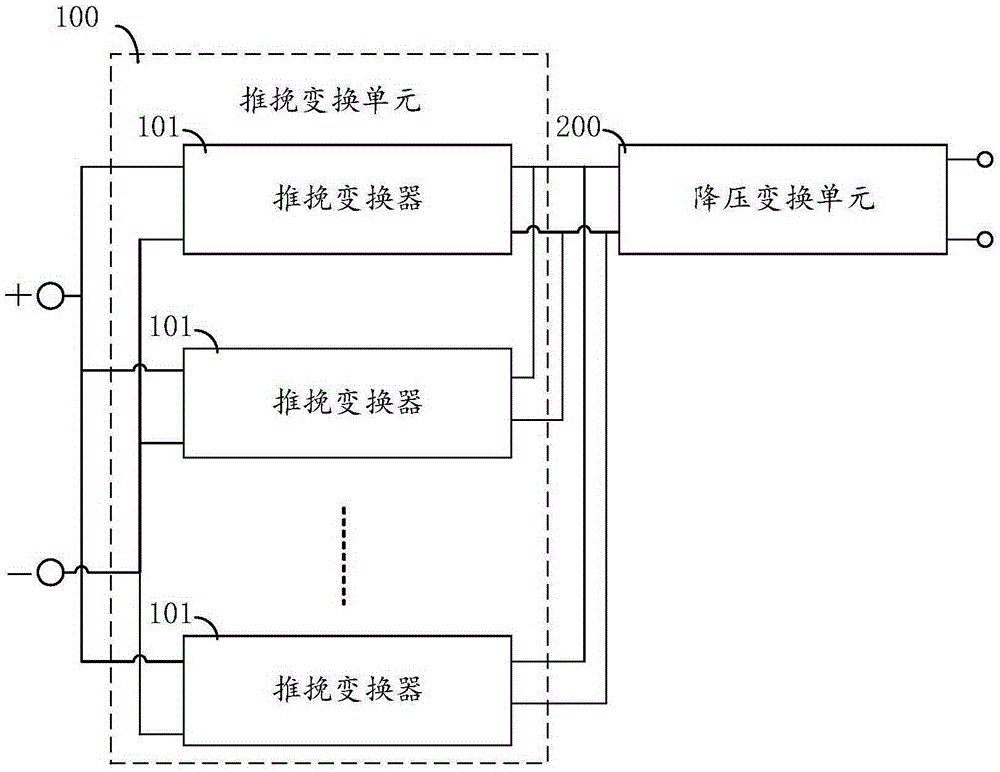

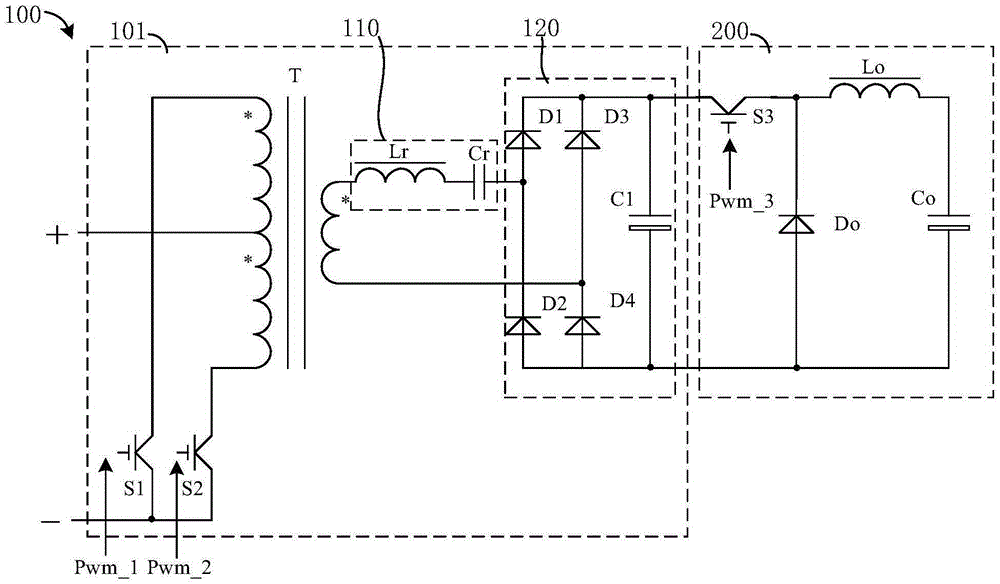

[0030] see figure 2 , in this embodiment, the DC / DC conversion circuit includes a push-pull converter 101 and a Buck conversion circuit, wherein the rectification module 120 of the push-pull converter 101 is a bridge rectification method.

Embodiment 2

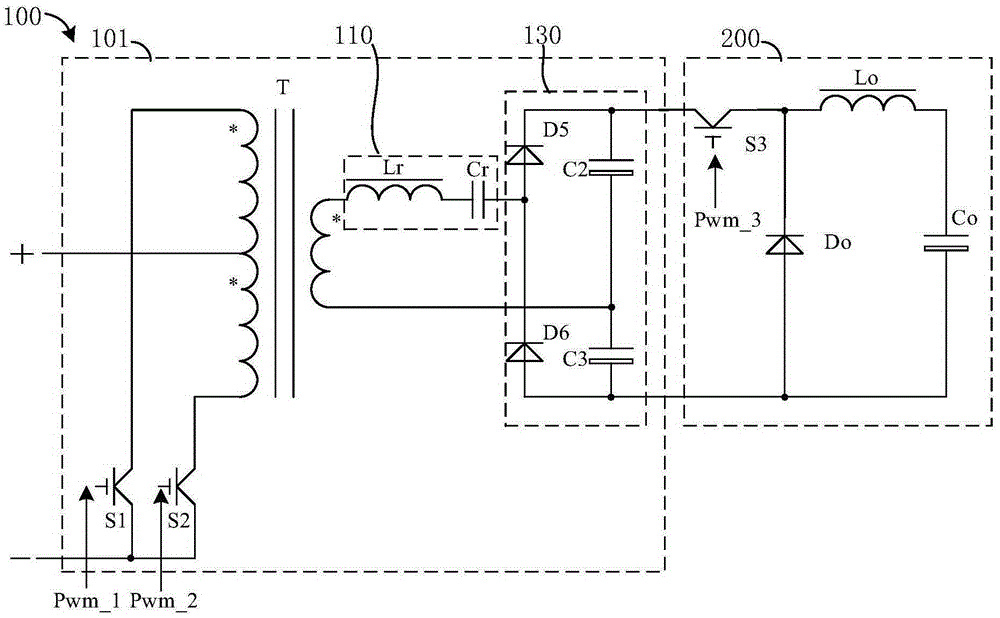

[0032] see image 3 , in this embodiment, the DC / DC conversion circuit includes a push-pull converter 101 and a Buck conversion circuit, wherein the rectification module 120 of the push-pull converter 101 is a voltage doubler rectification method.

[0033] In Embodiment 1 and Embodiment 2, the first drive signal Pwm_1 and the second drive signal Pwm_2 of the first switch tube S1 and the second switch tube S2 are complementary drives with a phase difference of 180°, and the preset maximum duty cycle, The dead time and the same fixed operating frequency as the resonant frequency of the resonant module 110, the soft start of the push-pull converter 101 can adopt the method of slowly releasing the driving duty cycle or gradually lowering the driving frequency from high to low to the steady-state frequency In this way, the push-pull output does not use any control, and the output of the entire converter is completely controlled by the closed-loop conversion circuit of the subsequen...

Embodiment 3

[0038] see Figure 4 , in this embodiment, the DC / DC conversion circuit includes two push-pull converters 101 and a Buck conversion circuit, and the two push-pull converters 101 are connected in parallel for input and output; the rectification module 120 of the push-pull converter 101 is a bridge rectifier The difference is that the rectification module 120 on each push-pull converter 101 includes a full-bridge rectifier, and the first filter capacitor C1 can only be provided on one of the rectification modules 120 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com