Pelteobagrus fulvidraco culturing feed and preparation method thereof

A technology for feeding and seawater fish, which is applied in the field of feeding for peltago catfish breeding and its preparation, and can solve problems such as unreasonable formula, low feeding efficiency for peltago catfish feeding, and insufficient nutrients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

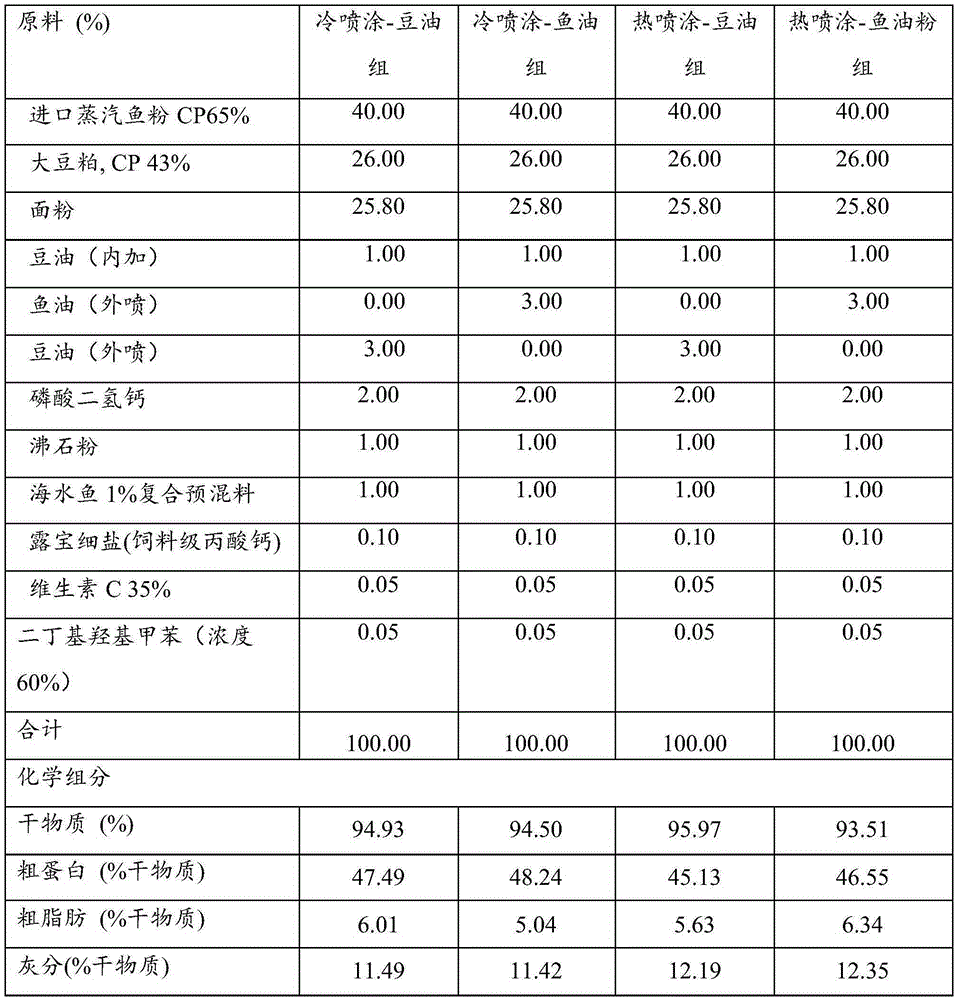

[0020] Embodiment 1: Feed nutritional composition comparison

[0021] In this embodiment, two different processing techniques (thermal spraying and cold spraying) are selected, and two different oil formulas are selected at the same time, namely the fish oil group and the soybean oil group. In the formulas, except for the addition of different oils and fats, other ingredients are the same; a total of four kinds are produced The different feeds were named cold spray-soybean oil group, cold spray-fish oil group, thermal spray-soybean oil group and thermal spray-fish oil group. The four feeds were equal in nitrogen and energy, respectively. The experimental raw materials were purchased uniformly and transported to each factory for production of feed. The parameters of the extruding process were consistent. , the results are shown in Table 1 and Table 2.

[0022] Table 1 Nutrient Levels

[0023]

[0024] Table 2 Amino Acid Composition

[0025] Amino acid (%)

[002...

Embodiment 2

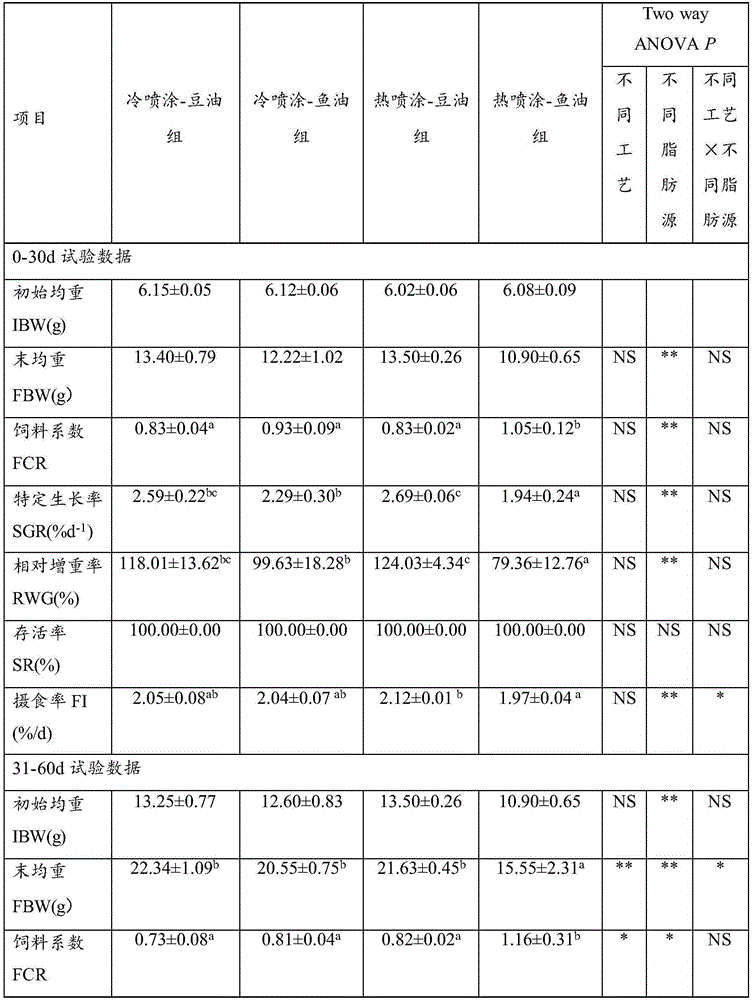

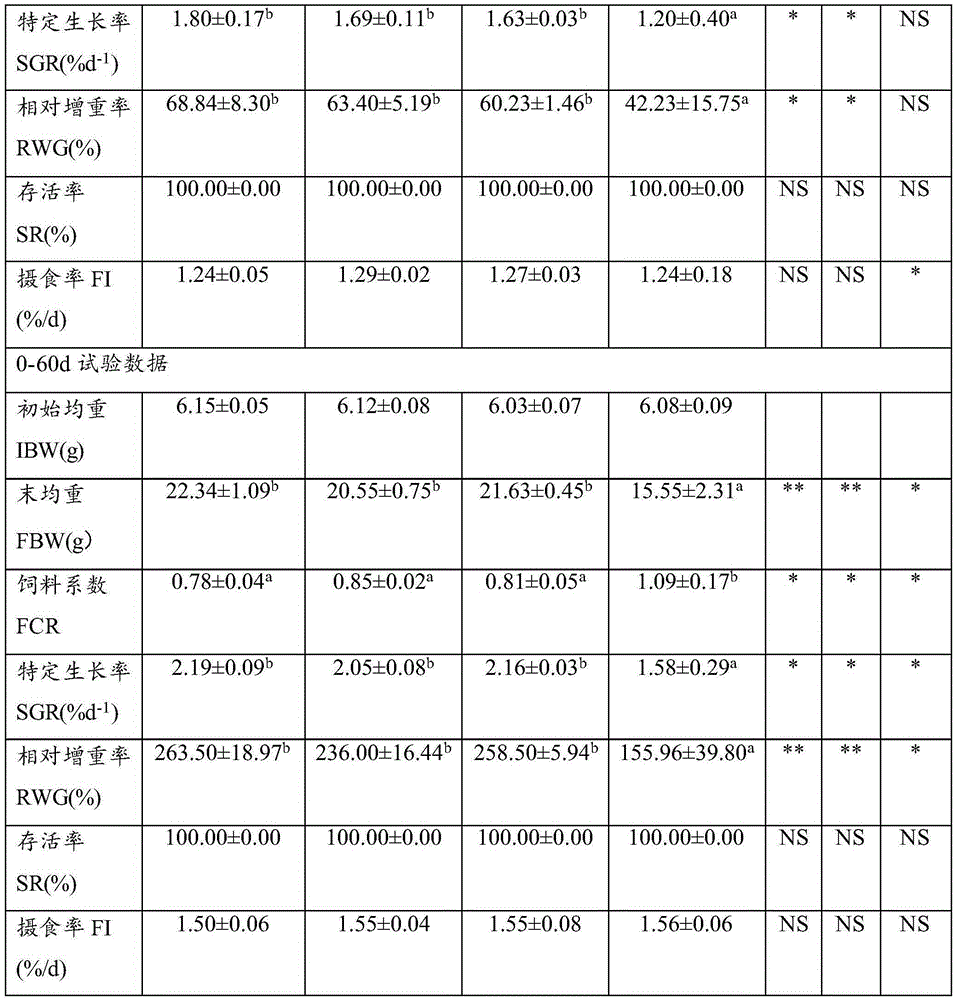

[0028] Embodiment 2: Effects of each group of feeds on the growth performance and survival rate of the yellow catfish

[0029] 1. Grouping

[0030] Grouping with reference to Example 1;

[0031] 2. Instruments and equipment

[0032] The volume of the breeding tanks used in the experiment is 200L, a total of 20, thermometers and electronic scales. The yellow catfish used in the experiment was purchased from Tangkou. Before the formal experiment, the yellow catfish was domesticated for 2 weeks to adapt to the environment. In the experiment, 1000 yellow catfish (about 6 g) with healthy constitution and uniform individual size were randomly divided into 5 treatment groups, each treatment group had 4 replicates, and each replicate had 50 yellow catfish. The feeding cycle was 60 days, and the apparently satiated animals were fed twice a day at 9:00 and 16:00, respectively. Weighing and sampling were recorded after the experiment. The breeding experiment was carried out in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com