Direct-heating type hot-pressing equipment suitable for producing large-size beryllium materials

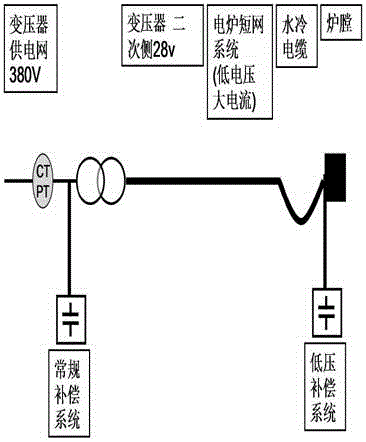

A hot-pressing equipment and direct-heating technology, applied in the field of powder metallurgy equipment, can solve problems such as low input power, overheating or smoke, and imperfect equipment mold design, and achieve the effect of increasing heating power and reducing the intensity of induced current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the present invention will be described in detail below with reference to examples. It should be understood that the examples are used to illustrate the present invention and not to limit the present invention. The scope and core content of the present invention are determined based on the claims.

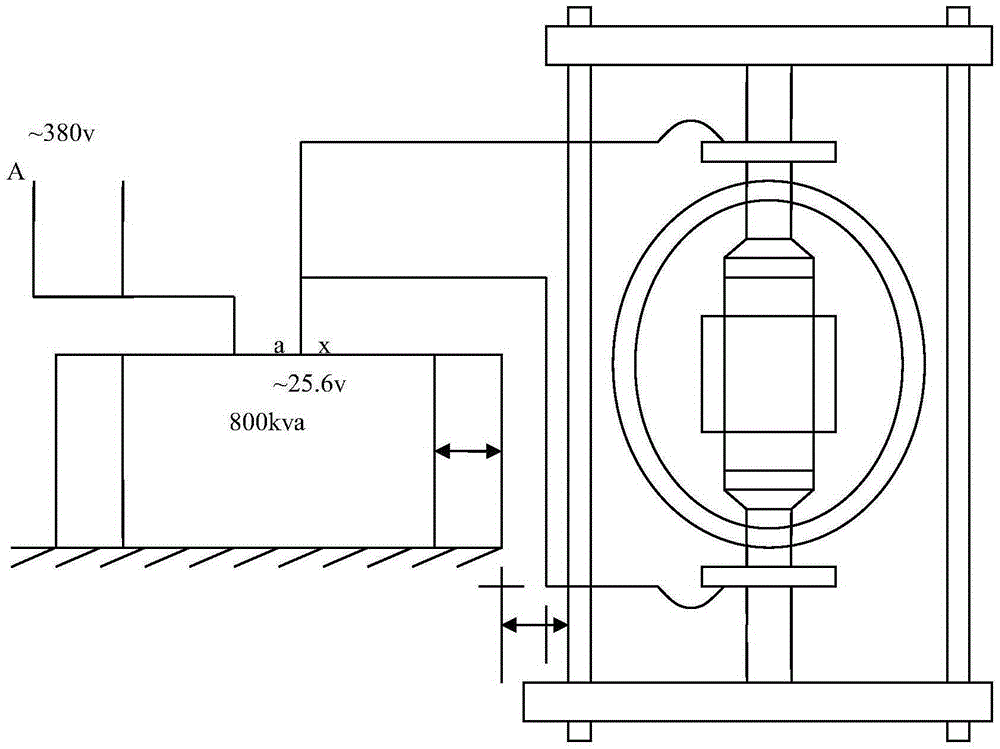

[0024] The embodiment of the present invention provides a direct heating type hot pressing equipment, specifically:

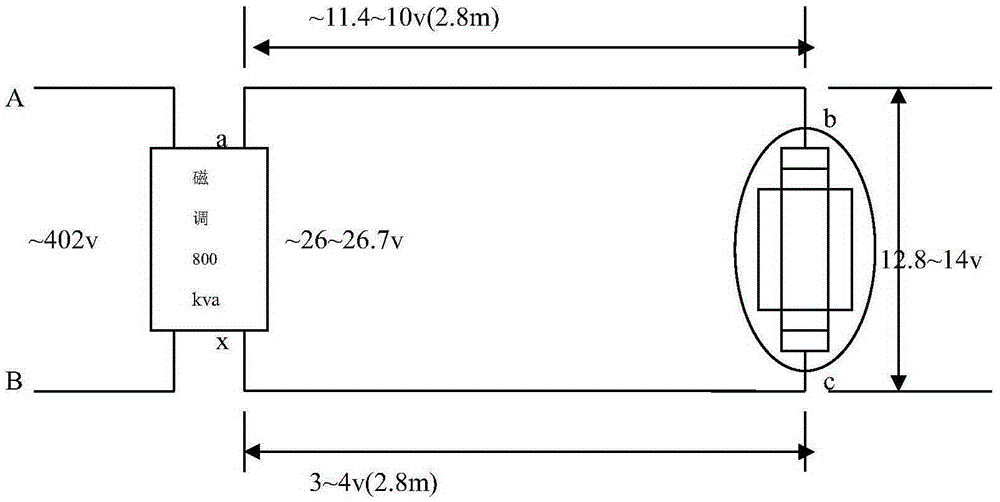

[0025] Step S1, change the short network from the existing copper busbar connection to the water-cooled cable connection:

[0026] Water-cooled cable adopts a conductive cross-section of 2000mm 2 , Length is 2.8m, quantity is 8 (upper 4 roots and lower 4 roots). When the working current is 25000A, the current density of the water-cooled cable is 3.125A / mm 2 . The conductor of the water-cooled cable is interwoven with multiple strands of soft copper wire, the diameter of a single bare copper wire is less than Φ0.6mm, and the material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com