A kind of single-batch large-scale synthetic nano-silver powder production method

A technology of nano silver powder and production method, applied in nanotechnology and other directions, can solve the problems of unusability, poor particle uniformity, existence of large particles, etc., and achieve the effect of strong continuous supply capacity and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

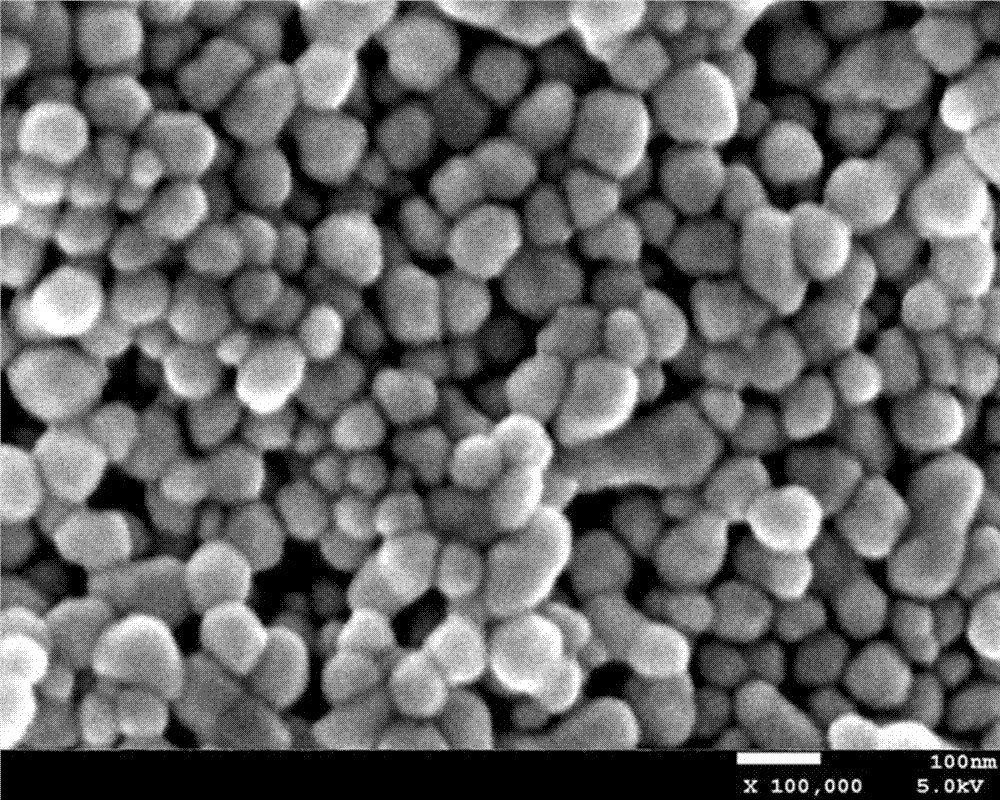

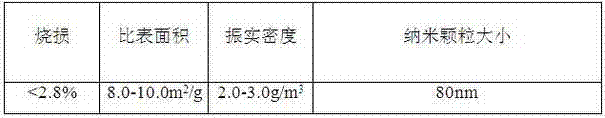

Image

Examples

Embodiment 1

[0030] The specific implementation steps of this embodiment are as follows:

[0031] (1) Use natural macromolecular water-soluble colloids with optical rotations in the range of -19.0~-24.0 or +27.0~+30.0 and add them into deionized water to form a colloidal solution;

[0032] (2) Adjust the temperature of the colloidal solution to 40~65°C, then add glucose to it, and stir until it dissolves;

[0033] (3) Use deionized water to configure silver nitrate solution, and add ammonia solution with a mass fraction of 20-40% under stirring until the solution becomes clear and transparent to obtain a silver amine complex ion solution;

[0034] (4) Add the obtained silver ammonium ion solution into the colloidal solution in which glucose is dissolved, the mass ratio of silver nitrate to glucose is 1:0.15~0.45, and it is obtained after the reaction is completed.

[0035] Natural macromolecular water-soluble colloids with optical rotations in the range of -19.0~-24.0 or +27.0~+30.0 are u...

Embodiment 2

[0037] In this embodiment, on the basis of the above-mentioned embodiments, the specific usage amount of each component and various process parameters are optimized, and the specific implementation steps are as follows:

[0038] (1) Add 7.0kg of natural peach gum with an optical rotation in the range of -19.0~-24.0 or +27.0~+30.0 into 240L of deionized water to dissolve it;

[0039] (2) Adjust the temperature of the colloid solution to 50~55°C, then add 4.1kg of glucose to it, and stir until it dissolves;

[0040] (3) Add 27.5kg of silver nitrate to 40L of deionized water to form a silver nitrate solution, and add 27.5L of ammonia solution with a mass fraction of 30% under stirring until the solution becomes clear and transparent to obtain a silver amine complex ion solution ;

[0041] (4) Add the obtained silver ammonium ion solution into the colloid solution in which glucose is dissolved at a rate of 0.45 L / min, and the product is obtained after the reaction is completed. ...

Embodiment 3

[0046] This embodiment optimizes the amount of specific use of each component, and various process parameters, and the specific implementation steps are as follows:

[0047] (1) Add 5.0kg of natural peach gum with an optical rotation in the range of -19.0~-24.0 or +27.0~+30.0 into 200~350L deionized water to dissolve it;

[0048] (2) Adjust the temperature of the colloidal solution to 50~55°C, then add 3.2kg of glucose to it, and stir until it dissolves;

[0049] (3) Add 20.8kg of silver nitrate to 30L of deionized water to form a silver nitrate solution, and add ammonia solution with a mass fraction of 20% under stirring until the solution becomes clear and transparent, and silver amine complex ion solution is obtained;

[0050] (4) Add the obtained silver ammonium ion solution to the colloidal solution in which glucose is dissolved at a rate of 0.3L / min. The mass ratio of silver nitrate to glucose is 1:0.075, and it is ready after the reaction is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| optical rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com