Method for preparing furfuryl alcohol by catalyzing furfural

A technology of furfural and furfuryl alcohol, which is applied in the field of catalyzing furfural to prepare furfuryl alcohol, can solve the problems of toxicity and non-sustainable development, and achieve the effects of environmental friendliness, mild reaction conditions and high furfuryl alcohol yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Preparation of nickel-loaded carbon nitride material:

[0018] Disperse 500mg of carbon nitride into 8ml of distilled water, add an aqueous solution containing 70mg of potassium nickelous chloride, stir at 80°C for 1h, then slowly add sodium borohydride solution (NaBH 4 / Pd molar ratio is 3:1), stirred at room temperature for 4h, filtered, washed with distilled water, and vacuum dried at 80°C to obtain a carbon nitride material loaded with 5% nickel.

[0019] Catalytic furfural prepares the method for furfuryl alcohol:

[0020] Accurately weigh 200mg of furfural and 25mg of 5% nickel-loaded carbon nitride material (10% nitrogen content) into the lining of the autoclave, and add 3ml of water. After sealing the stainless steel autoclave, it was ventilated with hydrogen for 3 times, and then flushed with 1MPa hydrogen at room temperature. Preheat the oil bath to the required temperature, put it into the autoclave, react at 120°C for 6h, stop the reaction, and cool to roo...

Embodiment 2~10

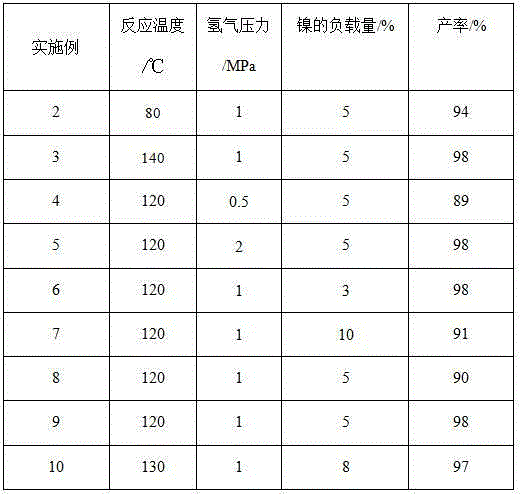

[0023] The difference from Example 1 lies in the reaction temperature, hydrogen pressure, nickel loading and nitrogen content of the carbon nitride material. The results are shown in Table 1.

[0024] Table 1

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com