Method for preparing bacterial cellulose from soybean molasses

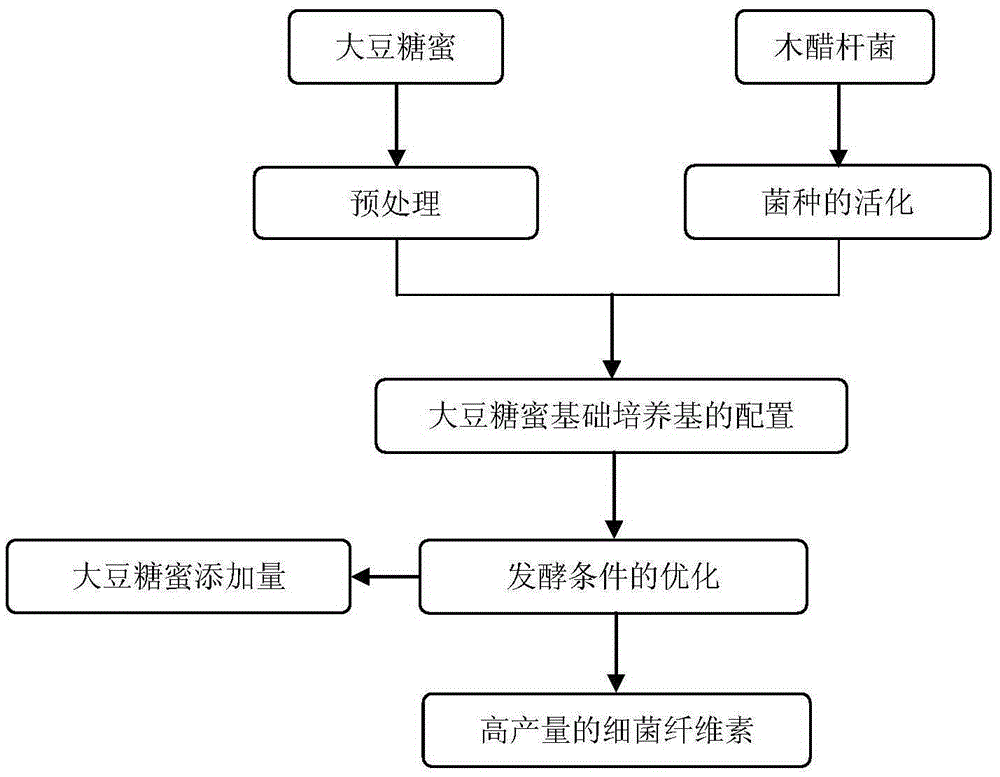

A technology of bacterial cellulose and soybean molasses is applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., and can solve the problems of incapable of industrialized production and popularization, high production cost, low bacterial cellulose yield, etc. Effects of high productivity, reduced production cost, and shortened culture time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Seed cultivation

[0019] The bacteria were inoculated in: glucose, 5g / L, NaCl, 5g / L, beef extract, 10g / L, yeast extract powder, 10g / L, pH value of 6.8 medium, at 180r / min, 30℃ Cultivate under the conditions for 24 hours to obtain seed liquid, and the strain is Acetobacter xylinum.

[0020] (2) Preparation of fermentation medium

[0021] Dilute the soybean molasses with water to make the concentration 10%, then adjust the pH value to 3.0 with 4mol / L sulfuric acid, acidify at 100°C for 60min, centrifuge, and take the supernatant;

[0022] According to the content of corn gluten powder per liter of the medium, 10g, Na 2 HPO 4 , 2g, citric acid, 1g, MgSO 4 , 0.1g, and the rest is supplemented with processed soybean molasses, and the pH value is adjusted to 7.

[0023] (3) Preparation of bacterial cellulose

[0024] After the Acetobacter xylinum seed liquid was fermented for 24 hours, inoculate it in the fermentation medium according to the inoculum amount of 10%,...

Embodiment 2

[0028] (1) Seed cultivation

[0029] The bacteria were inoculated in: glucose, 5g / L, NaCl, 5g / L, beef extract, 10g / L, yeast extract powder, 10g / L, pH value of 6.8 medium, at 180r / min, 30℃ Cultivate under the conditions for 24 hours to obtain seed liquid, and the strain is Acetobacter xylinum.

[0030] (2) Preparation of fermentation medium

[0031] Dilute the soybean molasses with water to make the concentration 20%, then adjust the pH value to 3.0 with 4mol / L sulfuric acid, acidify at 100°C for 60min, centrifuge, and take the supernatant;

[0032] According to the content of corn gluten powder per liter of the medium, 10g, Na 2 HPO 4 , 2g, citric acid, 1g, MgSO 4 , 0.1g, and the rest is supplemented with processed soybean molasses, and the pH value is adjusted to 7.

[0033] (3) Preparation of bacterial cellulose

[0034] After the Acetobacter xylinum seed liquid was fermented for 24 hours, inoculate it in the fermentation medium according to the inoculum amount of 10%,...

Embodiment 3

[0038] (1) Seed cultivation

[0039] The bacteria were inoculated in: glucose, 5g / L, NaCl, 5g / L, beef extract, 10g / L, yeast extract powder, 10g / L, pH value of 6.8 medium, at 180r / min, 30℃ Cultivate under the conditions for 24 hours to obtain seed liquid, and the strain is Acetobacter xylinum.

[0040] (2) Preparation of fermentation medium

[0041] Dilute soybean molasses with water to make the concentration 30%, then adjust the pH value to 3.0 with 4mol / L sulfuric acid, acidify at 100°C for 60min, centrifuge, and take the supernatant;

[0042] According to the content of corn gluten powder per liter of the medium, 10g, Na 2 HPO 4 , 2g, citric acid, 1g, MgSO 4 , 0.1g, and the rest is supplemented with processed soybean molasses, and the pH value is adjusted to 7.

[0043] (3) Preparation of bacterial cellulose

[0044] After the Acetobacter xylinum seed liquid was fermented for 24 hours, inoculate it in the fermentation medium according to the inoculum amount of 10%, fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com