Molybdenum dioxide combined electrode and preparation method and application thereof

A molybdenum dioxide and metal composite technology, applied in the field of electrochemistry, can solve problems such as large current performance to be improved, and achieve the effects of improving contact, improving utilization efficiency, and improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

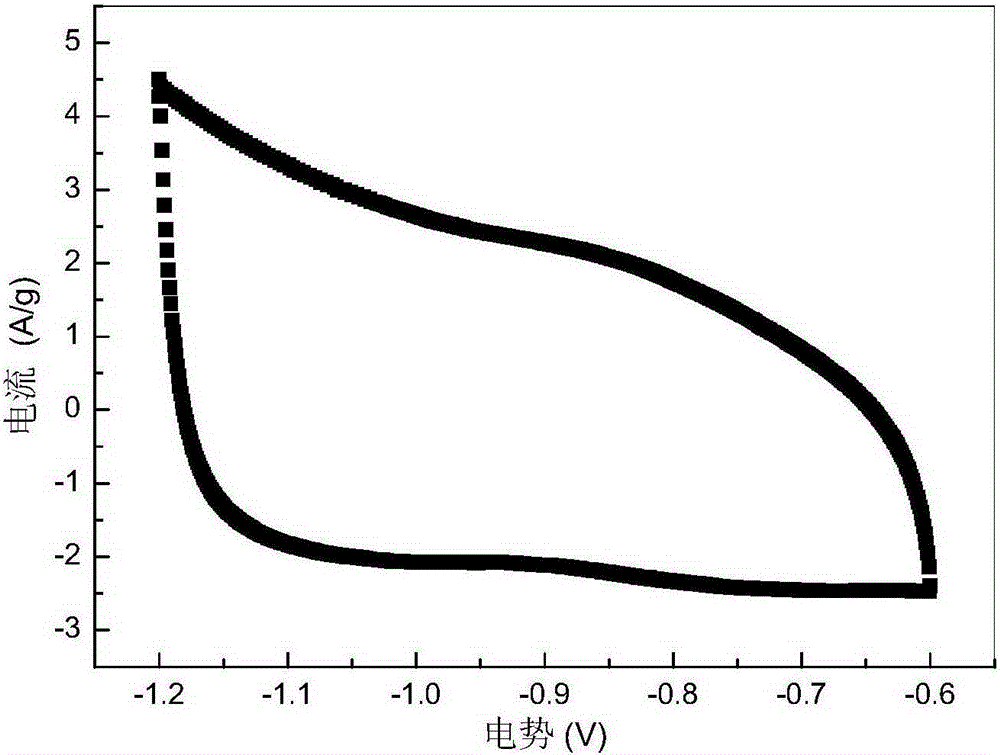

Image

Examples

Embodiment 1

[0057] Na 2 MoO 4 .2H 2 O and C 6 h 5 COONa is dissolved in water to prepare a mixed solution, and the pH value of the solution is adjusted to 10 with sodium hydroxide, and then Na is added to the solution. 2 SnO 3 .3H 2 O, formulated to contain MoO 4 2- 0.2mol / L, C 6 h 5 COO - 0.05mol / L and SnO 3 2- 0.02mol / L electrodeposition solution.

[0058] Cut the 304 stainless steel foil into an area of 4×1cm 2 The stainless steel belt is used as a current collector, and the current collector is ultrasonically washed with 10v% sulfuric acid aqueous solution and acetone in sequence, and finally rinsed with water and dried. A titanium mesh electrode coated with ruthenium oxide on the surface of 4 × 4 cm is used as the anode, the above mixed solution is the electrodeposition solution, and the current collector after surface cleaning is the cathode (the working area is 1 × 1 cm 2 ) for constant current electrodeposition with a current density of 2mA / cm 2 , the electrodepo...

Embodiment 2

[0061] The operation process is the same as in Example 1, except that the molybdate concentration in the mixed solution used is 0.8mol / L, the stannate concentration is 0.016mol / L, and the sodium benzoate concentration is 0.2mol / L. The area is 4×1cm 2 Carbon paper is used as a current collector, and the current density of constant current electrodeposition is 20mA / cm 2 , the measured tin content in the composite deposition layer is 6.2%, and the specific capacitance of the electrode active material is 388F / g.

Embodiment 3

[0063] The operation process is the same as in Example 1, except that the concentration of molybdate in the mixed solution used is 0.4mol / L, the concentration of stannate is 0.02mol / L, trisodium citrate replaces sodium benzoate, and the concentration is 0.1mol / L. The area is 4×1cm 2 The nickel strip is used as a current collector, and the current density of constant current electrodeposition is 5mA / cm 2 , the measured tin content in the composite deposition layer is 8.6%, and the specific capacitance of the electrode active material is 341F / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Than electricity | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com