Gas generator having increased combustion rate and combustion gas amount

A technology of gas generating agent and burning speed, which is applied in the direction of compressed gas generation, transportation and packaging, attacking equipment, etc., which can solve the problems of slow burning speed and low gas volume, and achieve internal pressure reduction, gas generating dose reduction, and weight reduction. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

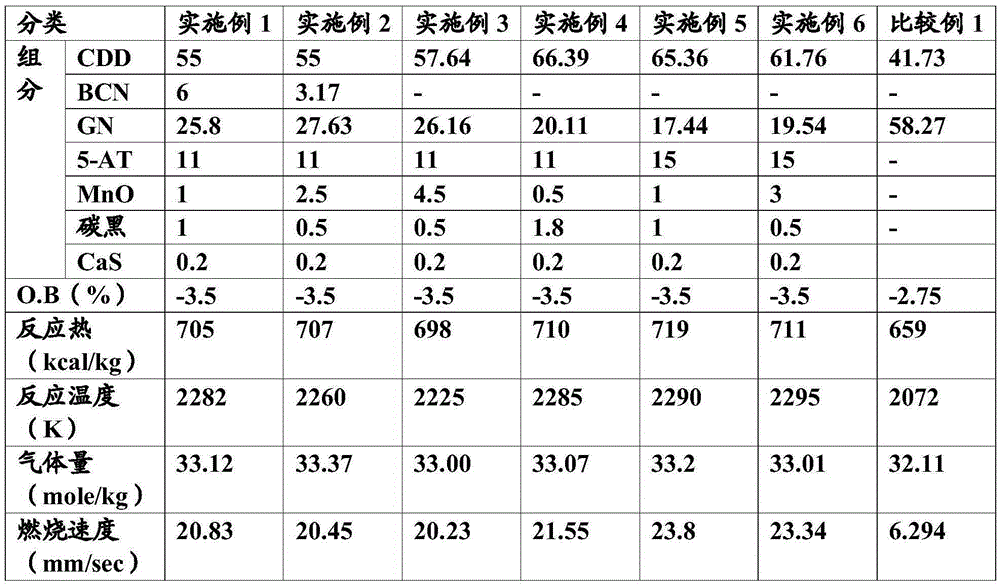

Embodiment 1

[0054] 55% by weight of copper dinitrate (CDD: Copper diaminedinitrate) as the main oxidant, 6% by weight of basic copper nitrate (BCN: Basic copper nitrate) as the auxiliary oxidant, and 25.8% by weight of guanidine nitrate (GN: Guanidine Nitrate) as the main fuel , 11% by weight of 5-aminotetrazole (5-AT: 5-Aminotetrazole) as a combustion rate-increasing fuel, 1% by weight of manganese oxide (MnO) as a metal oxide catalyst, 1% by weight of carbon black as a combustion catalyst % and calcium stearate (CaS) as an additive at a ratio of 0.2% by weight, weighed to a total amount of 400 g, put into a ball mill (Ball Mill) and mixed for 2 hours to prepare a dry mixture. Theoretically, the composition was calculated with an oxygen balance of -3.5%, a heat of combustion of 705kcal / kg, a combustion temperature of 2282K, a gas volume of 33.12mole / kg, and the result of measuring the combustion rate at 1000psi showed 20.83 mm / sec. The average particle size of manganese oxide (MnO) and ...

Embodiment 2

[0056] 55% by weight of copper dinitrate (CDD: Copper dinitrate) as the main oxidant, 3.17% by weight of basic copper nitrate (BCN: Basic copper nitrate) as the auxiliary oxidant, and 27.63% by weight of guanidine nitrate (GN: Guanidine Nitrate) as the main fuel , 11% by weight of 5-aminotetrazole (5-AT: 5-Aminotetrazole) as a combustion rate increasing fuel, 2.5% by weight of manganese oxide (MnO) as a metal oxide catalyst, 0.5% by weight of carbon black as a combustion catalyst % and calcium stearate (CaS) as an additive at a ratio of 0.2% by weight, weighed to a total amount of 400 g, put into a ball mill (Ball Mill) and mixed for 2 hours to prepare a dry mixture. Theoretically, the composition was calculated with an oxygen balance of -3.5%, a heat of combustion of 707kcal / kg, a combustion temperature of 2260K, a gas volume of 33.37mole / kg, and the result of measuring the combustion rate at 1000psi showed 20.45 mm / sec. The average particle size of manganese oxide (MnO) and...

Embodiment 3

[0058] 57.64 wt % of copper dinitrate (CDD: Copper dinitrate) as main oxidant, 26.16 wt % of guanidine nitrate (GN: Guanidine Nitrate) as main fuel, and 5-aminotetrazole (5-AT) as combustion rate increasing fuel : 11% by weight of 5-Aminotetrazole), 4.5% by weight of manganese oxide (MnO) as a metal oxide catalyst, 0.5% by weight of carbon black as a combustion catalyst, and 0.2% by weight of calcium stearate (CaS) as an additive The mixture was mixed, weighed into a total amount of 400 g, put into a ball mill (Ball Mill) and mixed for 2 hours to prepare a dry mixture. Theoretically, the composition was calculated with oxygen balance of -3.5%, heat of combustion 698kcal / kg, combustion temperature 2225K, gas amount 33mole / kg, and the result of measuring the combustion velocity at 1000psi showed 20.23mm / sec. The average particle size of manganese oxide (MnO) and carbon black is less than 1 μm, and the particle size of 5-15 μm is used for the rest of the raw materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com