Device for increasing superheat degree of smoke obtained after wet desulphurization and use method

A wet desulfurization and superheat technology, applied in separation methods, separation devices, chemical instruments and methods, etc., can solve the problems of easy blockage of heat exchangers, weak diffusion capacity and high failure rate, and achieve low resistance and increased superheat. , the effect of stable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

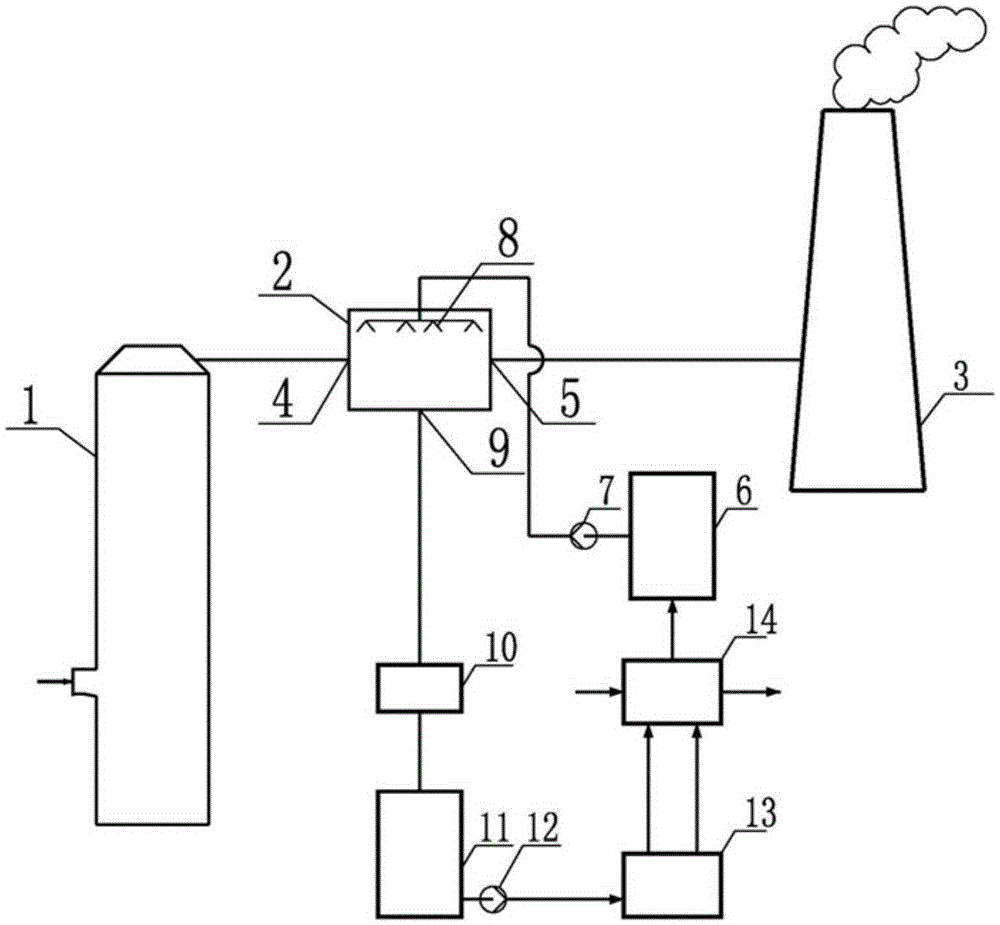

[0033] Such as figure 1 As shown, the saturated wet flue gas discharged from the desulfurization tower 1 with a temperature of about 50°C and a relative humidity of 100% enters the flue gas superheater 2 through the inlet 4 of the flue gas superheater, where the flue gas intersects with the absorption working medium Flow and direct contact for heat and mass exchange, part of the water vapor in the flue gas migrates to the absorption working fluid and releases heat, the moisture content of the flue gas decreases, the dew point temperature decreases, the dry bulb temperature increases, and the degree of superheat increases. Outlets 5 are combined and vented to atmosphere through chimney 3. Outside the flue gas superheater 2, there is a working medium pool 6 that delivers a set concentration of absorption working fluid to the flue gas superheater 2. The absorption working medium is input to the atomization nozzle 8 of the superheater through the absorption pump 7, and then passed...

Embodiment 2

[0037] The difference between this embodiment and embodiment 1 is:

[0038] A liquid receiving device is provided below the atomizing nozzle 8, and the liquid receiving device (a liquid receiving plate) includes a plurality of metal plates intersecting in the middle, and the middle part of each metal plate is lower than the two sides.

Embodiment 3

[0040] The difference between this embodiment and embodiment 1 is:

[0041] A filler is arranged below the atomizing nozzle 8 to increase the mass transfer area, reduce the volume of the equipment, and improve the dehumidification efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com