Systems for handling oily metal powders

A metal powder and waste liquid treatment technology, which is applied in the field of oily metal powder, can solve the problems that affect the impurity content of the grinding metal powder, fail to reach the standard amount of impurities, and the production process is not applicable, so as to reduce manpower and save manpower Material resources, improving the effect of waste liquid treatment system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

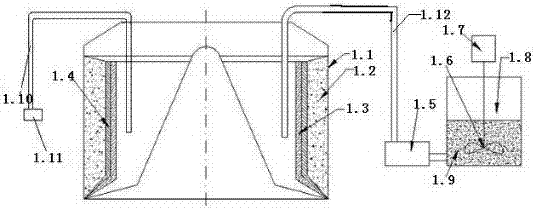

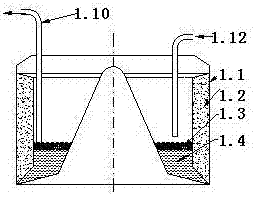

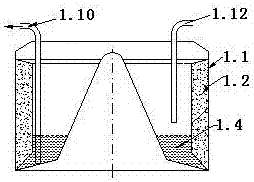

[0040] A system for processing oily metal powder, which includes a deoiling device, a corundum sand removal device and a waste liquid treatment device; the deoiling device includes an automatic feeding centrifuge 1 and an ultrasonic stirring tank 2; the corundum sand removal device includes a wet rotary screen 4 And a full countercurrent magnetic separator 5; the waste liquid treatment device is a ceramic membrane filter device 6.

[0041] Automatic feeding centrifuge, including centrifuge shell, feeding pipe 1.12, centrifuge slurry pump 1.5, centrifuge stirring paddle 1.6, slurry mixing tank 1.8 and speed regulating motor 1.7, one end of feeding pipe 1.12 extends into the centrifuge In the casing, the other end of the feed pipe 1.12 is connected to the centrifuge slurry pump 1.5, the centrifuge slurry pump 1.5 is connected to the slurry tank 1.8, the centrifuge stirring paddle 1.6 is located in the slurry mixing tank 1.8, and the upper end of the centrifuge stirring paddle 1.6...

Embodiment 2

[0047] A system for processing oily metal powder, which includes a deoiling device, a corundum sand removal device and a waste liquid treatment device; the deoiling device includes an automatic feeding centrifuge 1 and an ultrasonic stirring tank 2; the corundum sand removal device includes a wet rotary screen 4 And the full countercurrent magnetic separator 5 (the wet rotary screen 4 and the full countercurrent magnetic separator 5 are integrated, also known as the screening magnetic separation separator); the waste liquid treatment device is the ceramic membrane filter device 6.

[0048] Automatic feeding centrifuge, including centrifuge shell, feeding pipe 1.12, centrifuge slurry pump 1.5, centrifuge stirring paddle 1.6, slurry mixing tank 1.8 and speed regulating motor 1.7, one end of feeding pipe 1.12 extends into the centrifuge In the casing, the other end of the feed pipe 1.12 is connected to the centrifuge slurry pump 1.5, the centrifuge slurry pump 1.5 is connected to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com