Two-stage biological aerated filter and method for processing rural domestic wastewater

A biological aerated filter and domestic sewage technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor ammonia nitrogen nitrification effect and difficult to control operating conditions. Bacterial expansion and other problems, to achieve good operation management, realize the utilization of sludge resources, and good filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

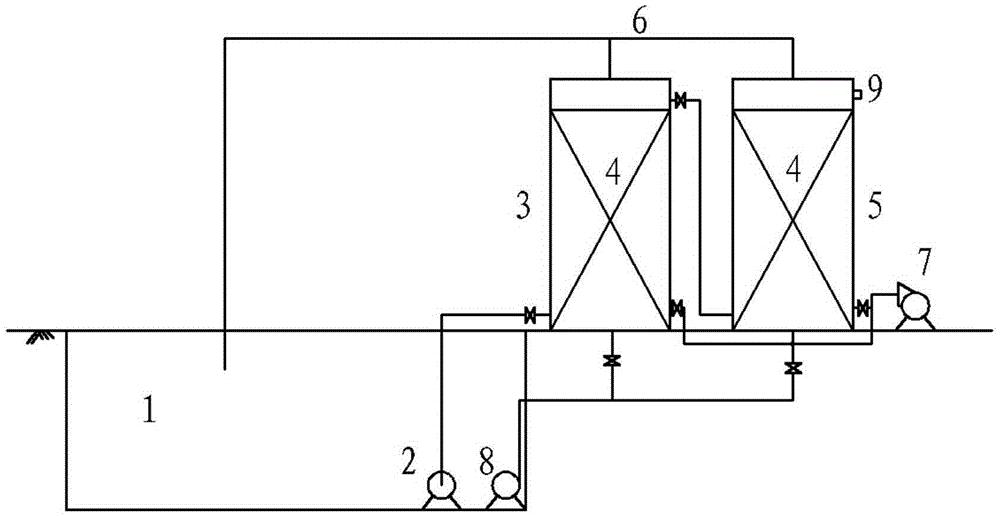

[0039] Such as figure 1 As shown, a two-stage biological aerated filter includes a regulating tank 1, a first-stage biological aerated filter 3, a bottom mud ceramsite layer 4, a second-stage biological aerated filter 5, and a tail gas utilization pipe 6 , fan 7 and backwash water pump 8, the adjustment tank 1 is connected to the bottom of the first section biological aerated filter 3 through a pipeline, one end of the pipeline is connected to the submersible pump 2 and placed in the adjustment tank 1, the first section biological aerated filter The upper part of 3 is connected to the lower part of the second-stage biological aerated filter 5 through pipelines, the fan 7 is respectively connected with the first-stage biological aerated filter 3 and the second-stage biological aerated filter 5 through pipelines, and the backwash water pump 8 Located in the regulating tank 1, it is connected to the first biological aerated filter 3 and the second biological aerated filter 5 thro...

Embodiment 2

[0049] Such as figure 1 As shown, a two-stage biological aerated filter includes a regulating tank 1, a first-stage biological aerated filter 3, a bottom mud ceramsite layer 4, a second-stage biological aerated filter 5, and a tail gas utilization pipe 6 , fan 7 and backwash water pump 8, the adjustment tank 1 is connected to the bottom of the first section biological aerated filter 3 through a pipeline, one end of the pipeline is connected to the submersible pump 2 and placed in the adjustment tank 1, the first section biological aerated filter The upper part of 3 is connected to the lower part of the second-stage biological aerated filter 5 through pipelines, the fan 7 is respectively connected with the first-stage biological aerated filter 3 and the second-stage biological aerated filter 5 through pipelines, and the backwash water pump 8 Located in the regulating tank 1, it is connected to the first biological aerated filter 3 and the second biological aerated filter 5 thro...

Embodiment 3

[0059] Such as figure 1 As shown, a two-stage biological aerated filter includes a regulating tank 1, a first-stage biological aerated filter 3, a bottom mud ceramsite layer 4, a second-stage biological aerated filter 5, and a tail gas utilization pipe 6 , fan 7 and backwash water pump 8, the adjustment tank 1 is connected to the bottom of the first section biological aerated filter 3 through a pipeline, one end of the pipeline is connected to the submersible pump 2 and placed in the adjustment tank 1, the first section biological aerated filter The upper part of 3 is connected to the lower part of the second-stage biological aerated filter 5 through pipelines, the fan 7 is respectively connected with the first-stage biological aerated filter 3 and the second-stage biological aerated filter 5 through pipelines, and the backwash water pump 8 Located in the regulating tank 1, it is connected to the first biological aerated filter 3 and the second biological aerated filter 5 thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com