Anti-wear anti-seize lubricant for drilling fluid

An anti-seize lubricant and drilling fluid technology, applied in the field of drilling, can solve the problems of unbearable high temperature of lubricating film, slow film-forming speed of lubricating film, weak anti-wear and friction-reducing effect, etc. The effect of improving the film forming speed and the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

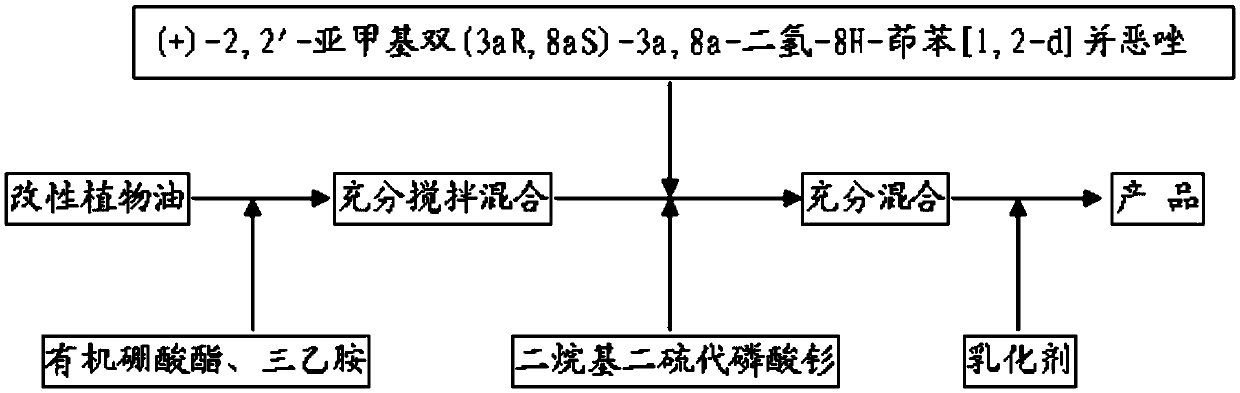

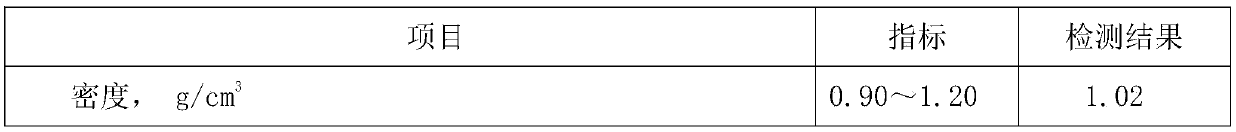

[0033] refer to figure 1 Shown, a kind of anti-wear and anti-seize lubricant for drilling fluid is made up of following components by weight: 70.5 parts of epoxidized (and / or sulfonated) modified vegetable oil (specifically U.S. Ruianbo H1 food grade general purpose lubricant), 5 parts tri-n-hexadecyl borate, 5 parts trioctyl borate, 10 parts triethylamine, 4 parts samarium dialkyl dithiophosphate, 0.5 parts (+)-2,2' - Methylenebis[(3aR,8aS)-3a,8a-dihydro-8H-indenebenzo[1,2-d]oxazole, 5 parts emulsifier.

[0034]

[0035]

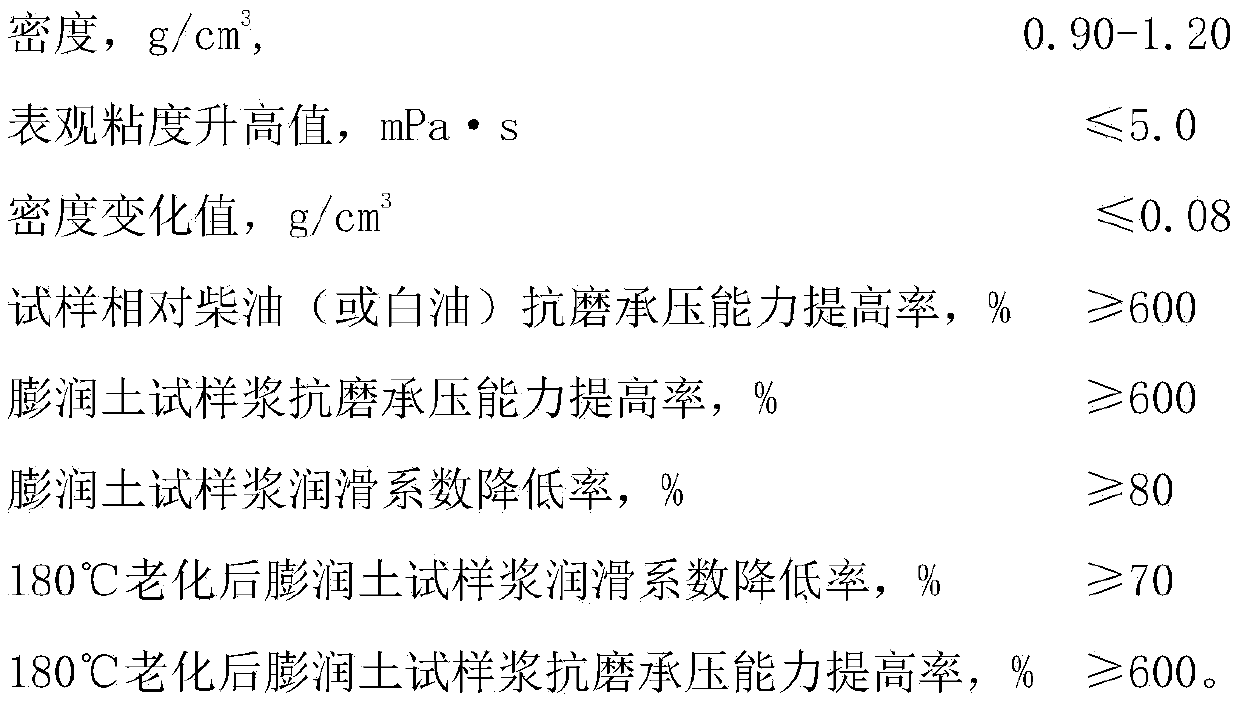

[0036] The meanings of the above indicators are as follows:

[0037] Apparent viscosity increase value, density change value: characterize the influence of lubricant on the basic properties of drilling fluid;

[0038] The increase rate of the anti-wear and pressure-bearing capacity of the sample relative to diesel oil (or white oil) represents the theoretical influence of the lubricant on the anti-wear and anti-friction performance of the drilling f...

Embodiment 2

[0086] refer to figure 1 As shown, a kind of anti-wear and anti-seize lubricant for drilling fluid is made up of following components by weight: 58.5 parts of epoxidized (and / or sulfonated) modified vegetable oil (specifically U.S. Ruianbo H1 food grade general purpose lubricant), 7.5 parts tri-n-hexadecyl borate, 7.5 parts trioctyl borate, 15 parts triethylamine, 6 parts samarium dialkyl dithiophosphate, 0.5 parts (+)-2,2' -Methylenebis[(3aR,8aS)-3a,8a-dihydro-8H-indenobenzo[1,2-d]oxazole, 5 parts of emulsifier (the test method is the same as in Example 1).

[0087]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com