Electromagnetic ultrasonic probe

An electromagnetic ultrasonic and magnetic shoe technology, which is applied in the direction of material analysis, measuring devices, and instruments using sound waves/ultrasonic waves/infrasonic waves. The effect of enhanced anti-interference ability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

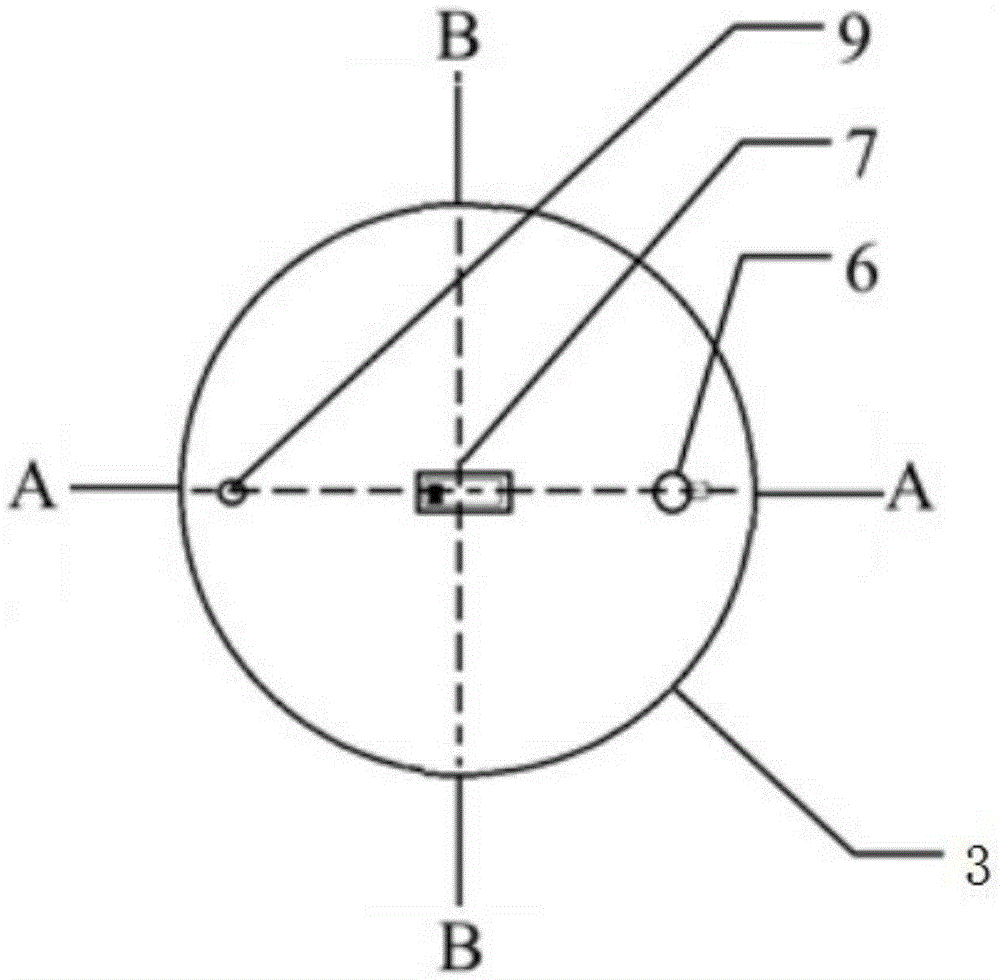

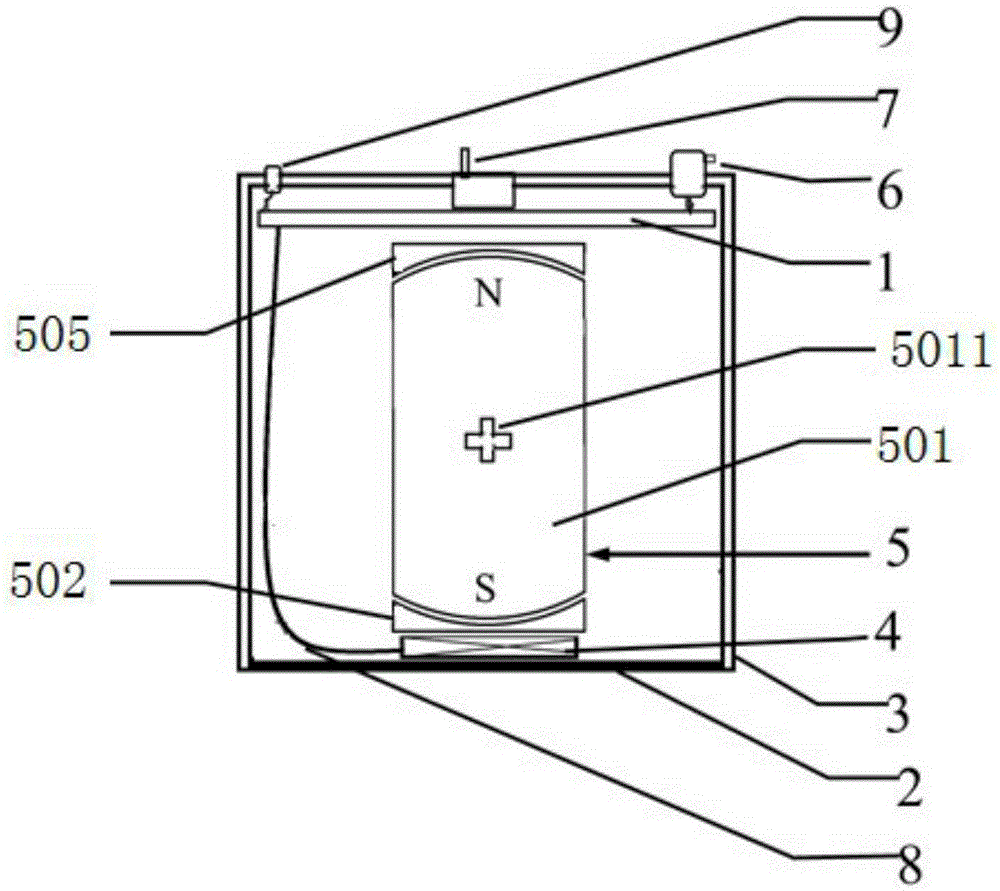

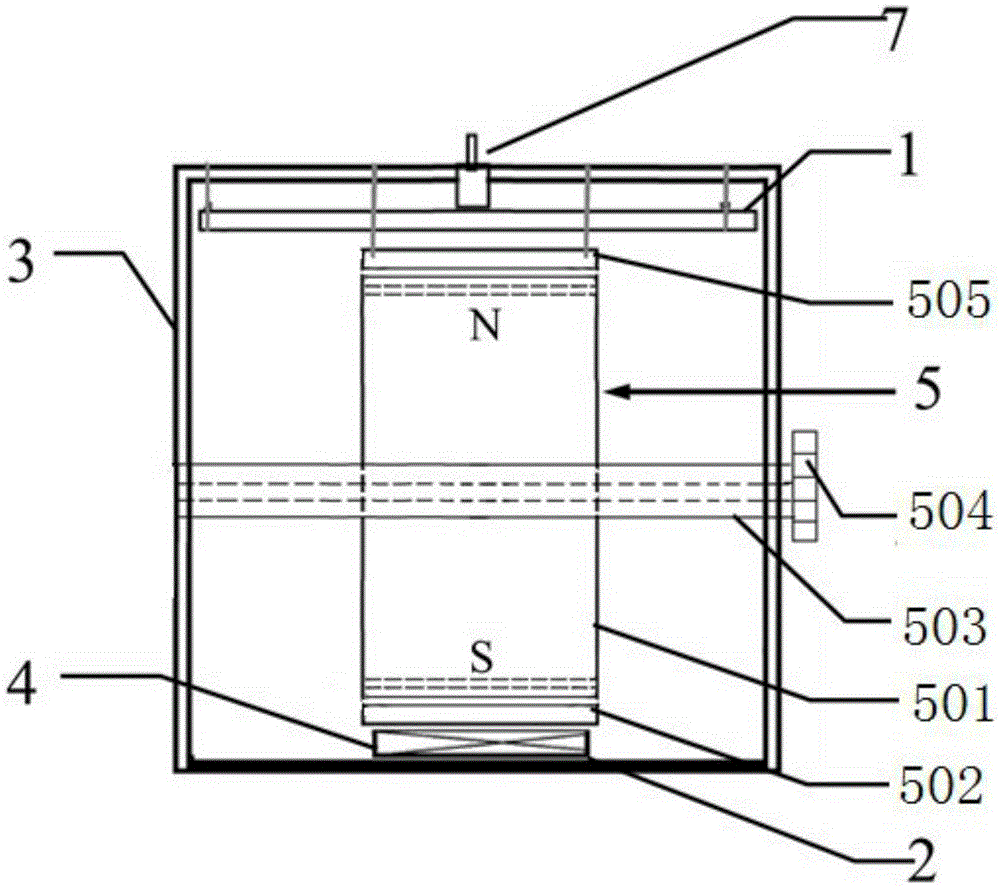

[0035] This embodiment adopts the electromagnetic ultrasonic probe of the above-mentioned connection mode, wherein the permanent magnet 501 is made of NdFeB material, the second arc-shaped magnetic shoe 505 is made of low-carbon steel material, and the shell 3 is made of magnetically conductive steel material. For the connection method of the primary amplifier circuit and the secondary amplifier circuit, see Figure 4 and Figure 5 .

[0036] Implement 170V square wave excitation on the piezoelectric probe 11 for 7 consecutive cycles with a frequency of 1MHz. The receiving coil 4 adopts a zigzag coil, and the toggle switch 7 is moved to the first gear. At this time, the gain of the preamplifier module 1 is 20dB. With respect to the ultrasonic signal of the microvolt level, this embodiment realizes the adjustment of the 10-fold gain of the received ultrasonic signal by calculating the function of the circuit, and the output voltage of the receiving coil 4 obtained is shown in ...

Embodiment 2

[0038] In this embodiment, the electromagnetic ultrasonic probe described in Embodiment 1 is adopted, and the piezoelectric probe is excited by a 170V square wave for 7 consecutive cycles with a frequency of 1 MHz. The receiving coil 4 adopts a folding coil, and the toggle switch 7 is moved to the second position. At this time, the gain of the preamplifier module is 40dB. Compared with the ultrasonic signal at the microvolt level, this embodiment realizes the adjustment of the 100-fold gain of the received ultrasonic signal through the function of the circuit. The output voltage of the receiving coil 4 is as shown in the figure As shown in Fig. 7(b), the ultrasonic signal directly emitted by the piezoelectric probe (the first signal in Fig. 7(b)) and the ultrasonic signal reflected by the crack can be clearly identified and distinguished from the collected signal (the second signal in Figure 7(b)), the signal amplitude is 10 times larger than the signal amplitude of the first g...

Embodiment 3

[0040] In this embodiment, the electromagnetic ultrasonic probe described in Embodiment 1 is used, and the piezoelectric probe 11 is excited by a 170V square wave for 7 consecutive cycles with a frequency of 1 MHz. The receiving coil adopts a folding coil, and the toggle switch is moved to the third position. At this time, the gain of the preamplifier module is 60dB. Compared with the ultrasonic signal at the microvolt level, this embodiment realizes the adjustment of the 1000-fold gain of the received ultrasonic signal through the function of the circuit. The output voltage of the receiving coil is shown in Figure 7(c). It is shown that the ultrasonic signal directly emitted by the piezoelectric probe (the first signal in Fig. 7(c)) and the ultrasonic signal reflected by the crack (Fig. 7(c) The second signal in the middle), the signal amplitude is about 100 times higher than the signal amplitude of the first gear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com