Freeze-dried original-taste chicken soup and manufacturing method thereof

A production method and chicken soup technology, which are applied in the fields of food freezing, food science, food preservation, etc., can solve the problems of short development time, easy moisture absorption and deliquescence, and easy breakage, and achieve simple production process, improved nutritional environment, and high edible value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

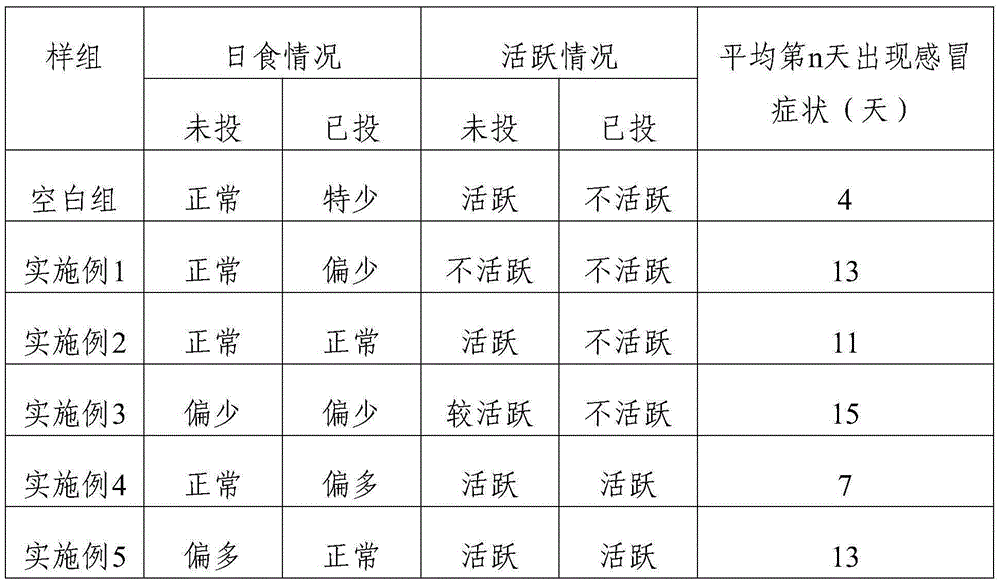

Examples

Embodiment 1

[0027] Step 1: Raw material selection and weighing

[0028] Native chicken 50kg, jujube 1kg, wolfberry 1kg, ginger 3kg, pepper 0.3kg, salt 1.2kg, monosodium glutamate 0.1kg, starch 0.4kg, carrageenan 0.05kg.

[0029] Step 2: Making Chicken Stock

[0030] After cutting the local chicken into pieces, put it into 130L of water, boil it for 10 minutes at a temperature of 100°C, then add jujube, wolfberry, ginger and pepper in turn, and simmer for 5 hours on a low heat. When the fire temperature is 80°C, the temperature is increased by 1°C every 5 minutes until the fire temperature is 90°C, and then heated at a constant temperature to obtain chicken stock.

[0031] Step 3: Making Original Chicken Soup

[0032] After mixing salt, monosodium glutamate, starch, and carrageenan, put it into the chicken broth and stir for 5 minutes, heat it at a constant temperature of 100°C for 30 minutes, and separate the solid and liquid to obtain concentrated soup and chicken-based solids.

[003...

Embodiment 2

[0036] Step 1: Raw material selection and weighing

[0037] Native chicken 60kg, jujube 2kg, wolfberry 0.8kg, ginger 2.3kg, pepper 0.5kg, salt 1kg, monosodium glutamate 0.1kg, starch 0.3kg, carrageenan 0.03kg.

[0038] Step 2: Making Chicken Stock

[0039] Cut the native chicken into 180L water, boil it in water at 99°C for 20 minutes, mix the jujube, wolfberry, ginger, and pepper evenly, put it in water, and simmer for 6 hours on low heat. At an initial fire temperature of 90°C, the temperature is reduced by 2°C every 5 minutes to a fire temperature of 85°C, and then heated at a constant temperature to obtain chicken stock.

[0040] Step 3: Making Original Chicken Soup

[0041] After mixing salt, monosodium glutamate, starch, and carrageenan, put it into the chicken broth and stir for 5 minutes, heat it at a constant temperature of 95°C for 40 minutes, and separate the solid and liquid to obtain concentrated soup and chicken-based solids.

[0042] Step 4: Molding Packaging...

Embodiment 3

[0045] Step 1: Raw material selection and weighing

[0046] Chicken 55kg, jujube 1.7kg, wolfberry 0.5kg, ginger 2.7kg, pepper 0.3kg, salt 1.5kg, monosodium glutamate 0.15kg, starch 0.35kg, carrageenan 0.03kg.

[0047] Step 2: Making Chicken Stock

[0048] Cut the local chicken into 154L water, boil it at 98°C for 15 minutes, then add ginger, jujube, pepper, and wolfberry in sequence, the time interval of adding materials is 2 minutes, and then simmer for 5.5 hours on low heat , the low-fire stewing is at an initial fire temperature of 80°C, the temperature is raised by 2°C every 5 minutes to a fire temperature of 89°C, and then heated at a constant temperature to obtain chicken stock.

[0049] Step 3: Making Original Chicken Soup

[0050] After mixing salt, monosodium glutamate, starch, and carrageenan, put it into the chicken broth and stir for 6 minutes, heat it at a constant temperature of 96°C for 30 minutes, and separate the solid and liquid to obtain concentrated soup ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com