VAV control system

A control system and variable air volume technology, applied in the direction of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as affecting work efficiency, discharge of unfavorable polluting gases, waste of electric energy, etc., to improve safety and avoid blowing. Discomfort, the effect of improving exhaust efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

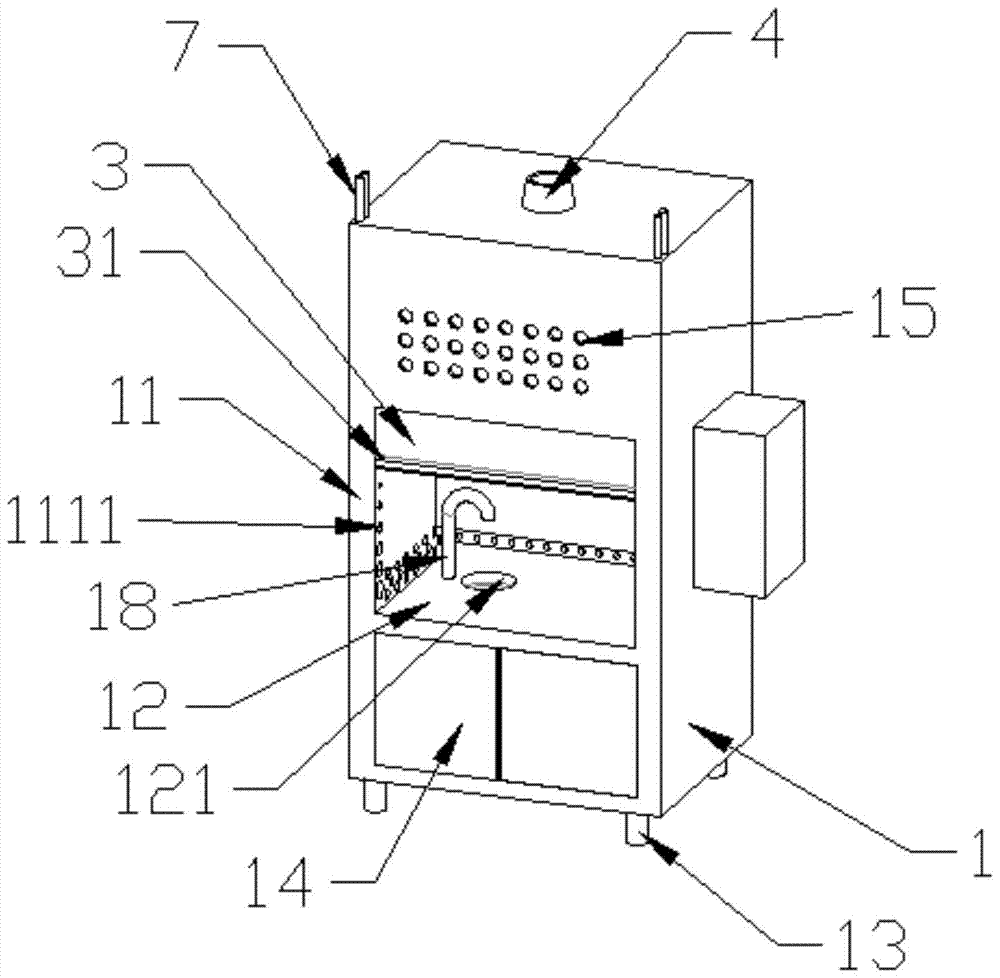

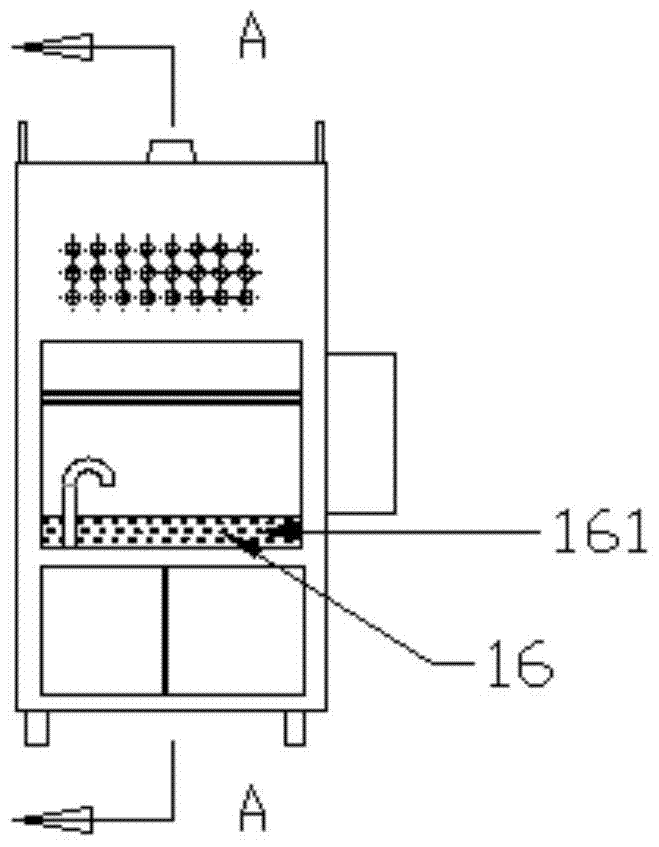

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

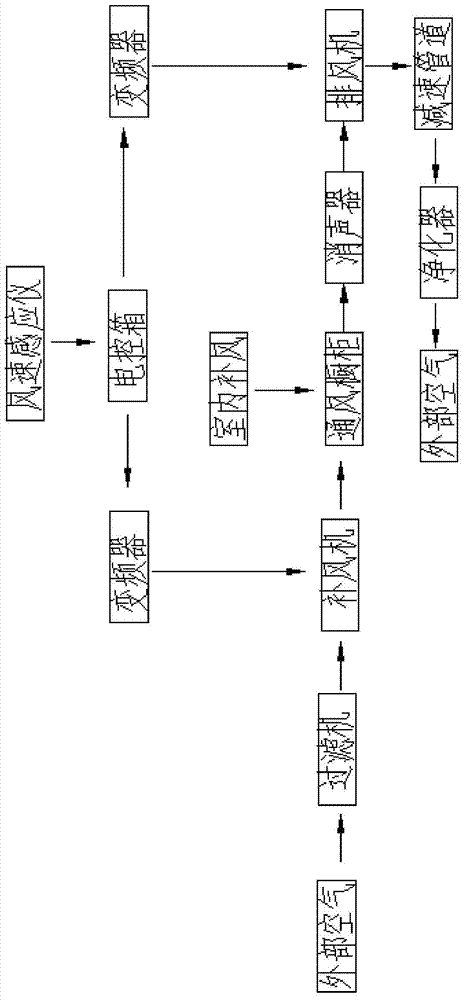

[0022] Such as figure 1 , figure 2 and Figure 4 As shown, the present invention is a variable air volume control system, which includes a box body 1, a sliding door 3, an air outlet 4, an anemometer 5, an air supply pipe 7, a step deflector 8, a supply fan, an exhaust fan, and an electric control box , and frequency converter.

[0023] The ventilation cabinet comprises a box body 1, the box body 1 is arranged on a horizontal plane, a workbench 12 is provided inside the box body 1, an opening is provided on one side of the box body 1, and front columns 11 are arranged on both sides of the opening, and the front column 11 is The hollow body and the inside are provided with a first air supply hole 1111, the first air supply hole 1111 is located above the workbench 12, the cavity body of the front column 11 communicates with the first air sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com