Super-hydrophobic coating and preparation method thereof

A technology of super-hydrophobic coatings and water baths, applied in the direction of coatings, etc., can solve the problems of troublesome preparation, harsh conditions, unfavorable coating hydrophobic properties, etc., and achieve the effect of improving wear resistance and enhancing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

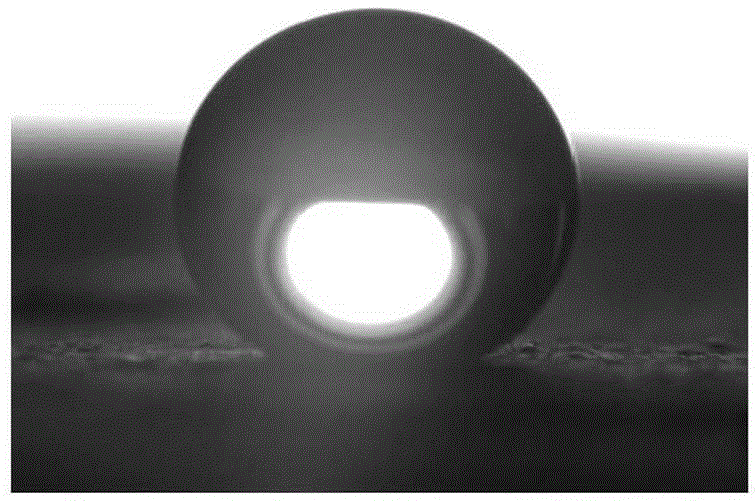

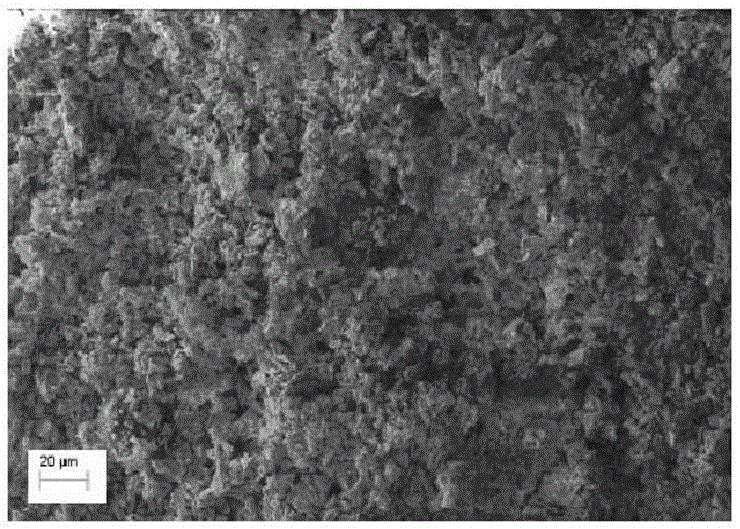

[0035] A kind of superhydrophobic coating of the present invention, this superhydrophobic coating comprises the component of following mass parts: 7.5 parts of polyvinylidene fluoride resins, 5 parts of polymethyl methacrylates, 60 parts of N, N-dimethylformamide, 27.5 parts of ceria particles, wherein the average particle diameter of ceria particles is 10 μm.

[0036] A kind of preparation method of the superhydrophobic coating of above-mentioned present embodiment, comprises the following steps: first 7.5 parts of polyvinylidene fluoride resins, 5 parts of polymethyl methacrylates, 60 parts of N,N-dimethylformamide are mixed, Stir in a water bath at 70°C to fully dissolve the resin to obtain a mixed resin; then add cerium oxide particles and stir thoroughly to obtain a superhydrophobic coating.

[0037] Coat the superhydrophobic coating prepared above on the glass fiber reinforced epoxy resin-based composite substrate after sanding with sandpaper (such as No. 400 sandpaper),...

Embodiment 2

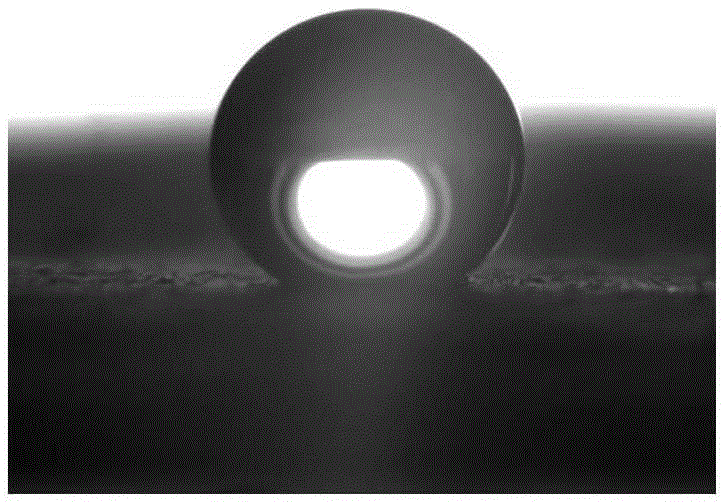

[0045] A kind of superhydrophobic coating of the present invention, this superhydrophobic coating comprises the component of following mass parts: 7.5 parts of polyvinylidene fluoride resins, 5 parts of polymethyl methacrylates, 60 parts of N, N-dimethylformamide, 27.5 parts of ceria particles, chopped carbon fibers accounting for 3‰ of the total mass of the paint, wherein the average particle diameter of the ceria particles is 10 μm, and the length of the chopped carbon fibers is 3 mm.

[0046] A kind of preparation method of the superhydrophobic coating of above-mentioned present embodiment, comprises the following steps: earlier with 7.5 parts of polyvinylidene fluoride resins, 5 parts of polymethyl methacrylates, 60 parts of N, N-dimethylformamide are mixed, Stir in a water bath at 70°C to fully dissolve the resin to obtain a mixed resin; then add cerium oxide particles and chopped carbon fibers and stir thoroughly to obtain a superhydrophobic coating.

[0047] The superhy...

Embodiment 3

[0052] A superhydrophobic coating of the present invention and its preparation method are basically the same as in Example 1, except that the substrate used is glass. The coating surface of the obtained superhydrophobic coating has a contact angle with water of 151° to 154°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com