A kind of electric contact material and preparation method thereof

An electrical contact material and copper alloy technology are applied in the field of graphene-enhanced copper-based electrical contact composite materials and their preparation to achieve the effects of reducing production costs, improving wear resistance, and avoiding uneven distribution of alloying elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

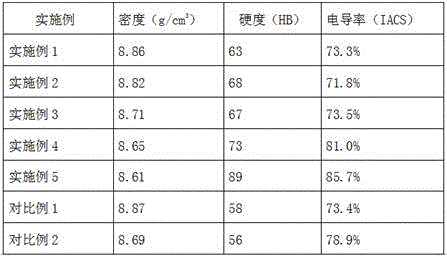

Examples

Embodiment 1

[0020] (1) The alloy powder containing 0.15% bismuth, 0.1% zinc and 99.75% copper is made into 200 mesh copper alloy powder by gas atomization method.

[0021] (2) Graphene and copper-0.15% bismuth-0.1% zinc alloy powder with 1-5 layers are loaded into the ball mill at a weight ratio of 0.1:99.9. 100r / min, in the process of ball milling and mixing, forward ball milling for 15 minutes, stop for 5 minutes, counterclockwise ball milling for 15 minutes, stop for 5 minutes, work alternately according to this, ball milling time is 6 hours, and obtain a powder evenly mixed with graphene and copper alloy .

[0022] (3) Put the mixed powder into the mold for cold pressing, the pressure is 600MPa, and the holding time is 3 minutes. Put the cold-pressed block into the vacuum sintering furnace (vacuum degree: 1.0*10 -3 Pa) for sintering, the sintering temperature is 700°C, and the holding time is 4 hours.

[0023] (4) The blank is secondary molded, the pressure is 200MPa, and the holdi...

Embodiment 2

[0025] (1) The alloy powder containing 0.5% bismuth, 3.0% zinc and 96.5% copper is made into 300 mesh copper alloy powder by gas atomization method.

[0026] (2) Graphene and copper-0.5% bismuth-3.0% aluminum alloy powder with a layer number of 1-10 are loaded into the ball mill at a weight ratio of 0.2:99.8. 250r / min, during the mixing process of ball milling, forward ball milling for 20 minutes, stop for 5 minutes, counterclockwise ball milling for 20 minutes, stop for 5 minutes, work alternately according to this, ball milling time is 2 hours, and obtain evenly mixed powder of graphene and copper alloy .

[0027] (3) Put the mixed powder into the mold for cold pressing, the pressure is 400MPa, and the holding time is 3 minutes. Put the cold-pressed block into the vacuum sintering furnace (vacuum degree: 5.0*10 -1 Pa) for sintering, the sintering temperature is 900°C, and the holding time is 2 hours.

[0028] (4) Secondary molding of the blank with a pressure of 500MPa an...

Embodiment 3

[0030] (1) The alloy powder containing 0.4% bismuth, 1.0% zinc and 98.6% copper is made into 200 mesh copper alloy powder by gas atomization method.

[0031] (2) Put graphene and copper-0.4% bismuth-1.0% zinc alloy powder with layers of 1-10 layers into the ball mill at a weight ratio of 0.2:99.8. The ball mill tank is first evacuated and then filled with inert gas for protection. The rotation speed is 200r / min. During the mixing process of ball milling, mill clockwise for 20 minutes, stop for 5 minutes, counterclockwise ball mill for 20 minutes, stop for 5 minutes, and work in this cycle. The total mixing time is 3 hours, and the graphene and copper alloy are uniformly mixed. of powder.

[0032] (3) Put the mixed powder into the mold for cold pressing, the pressure is 400MPa, and the holding time is 3 minutes. Put the cold-pressed block into the vacuum sintering furnace (vacuum degree: 1.0*10 -1 Pa) for sintering, the sintering temperature is 750°C, and the holding time is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com