Copper alloy for electronic and electrical equipment, plastically worked copper alloy material for electronic and electrical equipment, and component and terminal for electronic and electrical equipment

一种电子电气、塑性加工的技术,应用在热处理设备、金属材料涂层工艺、制造工具等方向,能够解决产品成品率降低、夹杂物、加工易产生缺陷等问题,达到抑制缺陷的产生、力学性能优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

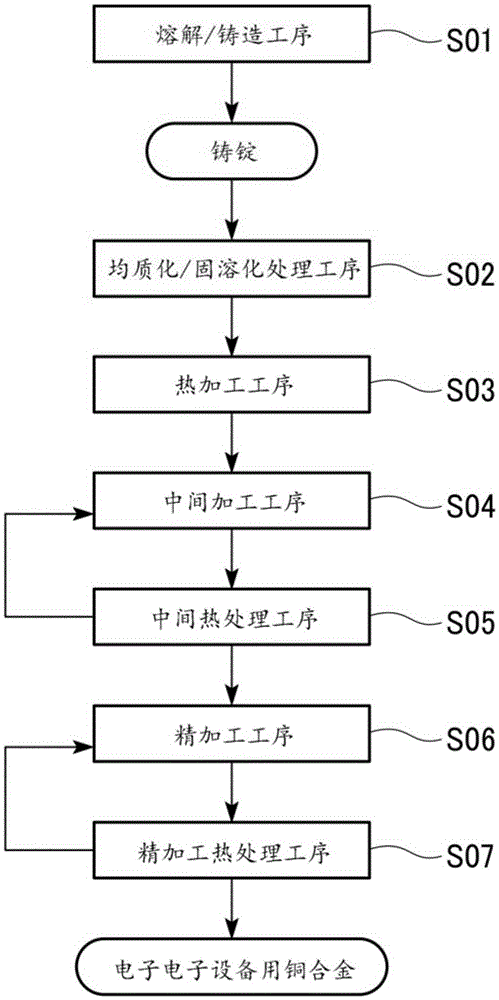

no. 1 approach

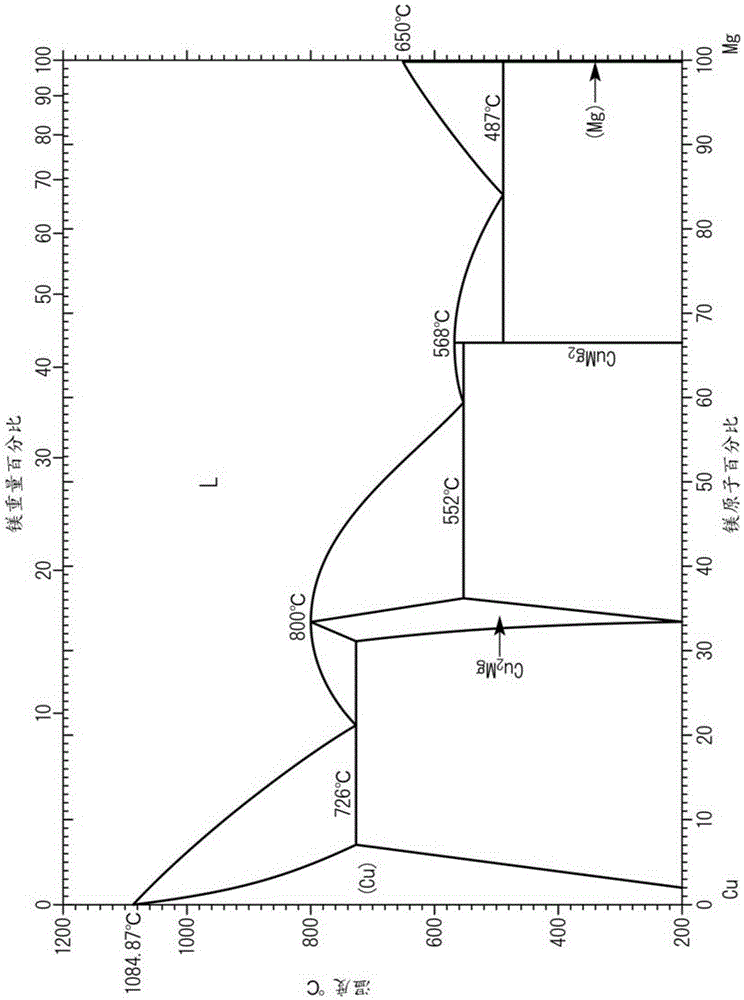

[0058] In the component composition of the copper alloy for electrical and electronic equipment according to this embodiment, Mg is contained in the range of 1.3% by mass to 2.8% by mass, and the remainder is actually Cu and unavoidable impurities, so-called Cu-Mg binary. Elemental alloys.

[0059] In addition, in the copper alloy for electronic and electrical equipment according to the present embodiment, the 0.2% yield strength is set to 400 MPa or more.

[0060] Here, when the content of Mg is defined as A atomic %, the electrical conductivity σ (%IACS) is set to σ≤1.7241 / (-0.0347×A 2 +0.6569×A+1.7)×100.

[0061] In addition, under scanning electron microscope observation, the average number of intermetallic compounds whose main components are Cu and Mg having a particle size of 0.1 μm or more is 1 piece / μm 2 the following.

[0062] That is, the copper alloy for electrical and electronic equipment according to the present embodiment is a Cu-Mg supersaturated solid soluti...

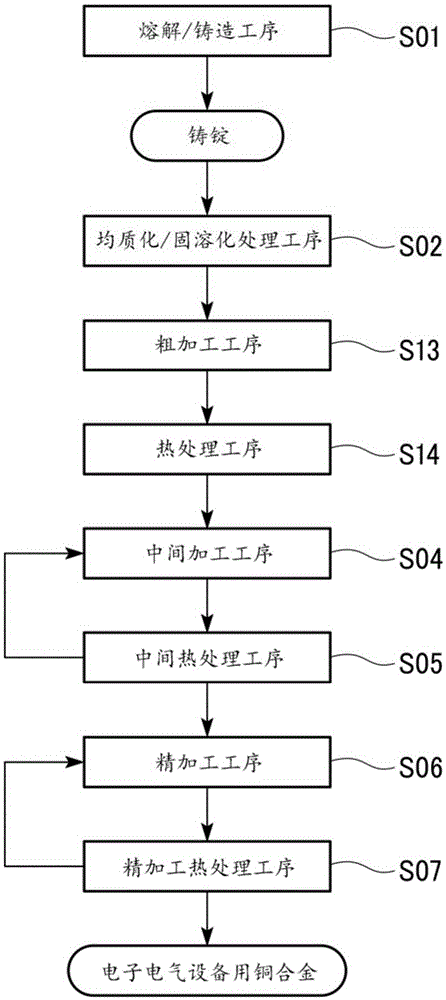

no. 2 approach

[0135] Next, the copper alloy for electrical and electronic devices according to the second aspect of the present invention will be described.

[0136] The composition of the copper alloy for electronic and electrical equipment according to this embodiment contains Mg in the range of 1.3% by mass to 2.8% by mass, and the remainder is actually Cu and unavoidable impurities, so-called Cu-Mg binary system. alloy.

[0137] In addition, in the copper alloy for electronic and electrical equipment according to the present embodiment, the contents of H, O, S, and C as impurity elements are specified as follows.

[0138] H: 10 mass ppm or less

[0139] O: 100 mass ppm or less

[0140] S: 50 mass ppm or less

[0141] C: 10 mass ppm or less

[0142] In addition, in the copper alloy for electrical and electronic equipment of the present embodiment, the X-ray diffraction intensity from the {111} plane on the plate surface is I{111}, and the X-ray diffraction intensity from the {200} pl...

no. 3 approach

[0158] Next, a copper alloy for electronic and electrical equipment according to a third embodiment of the present invention will be described.

[0159] The composition of the copper alloy for electrical and electronic equipment according to the present embodiment contains Mg in the range of 1.3% by mass to 2.8% by mass, and the remainder is actually Cu and unavoidable impurities, so-called binary Cu-Mg. Department of alloys.

[0160] In addition, in the copper alloy for electronic and electrical equipment according to the present embodiment, the contents of H, O, S, and C as impurity elements are specified as follows.

[0161] H: 10 mass ppm or less

[0162] O: 100 mass ppm or less

[0163] S: 50 mass ppm or less

[0164] C: 10 mass ppm or less

[0165] In addition, the copper alloy for electrical and electronic equipment of the present embodiment may be configured such that the yield ratio YS / TS calculated from the strength TS and the 0.2% yield strength YS when a tensil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com