Hollow fiber composite nanofiltration membrane and preparation method thereof

A fiber composite and nanofiltration membrane technology, applied in the field of separation membranes, can solve problems such as poor pollution resistance, high water intake requirements, and easy fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

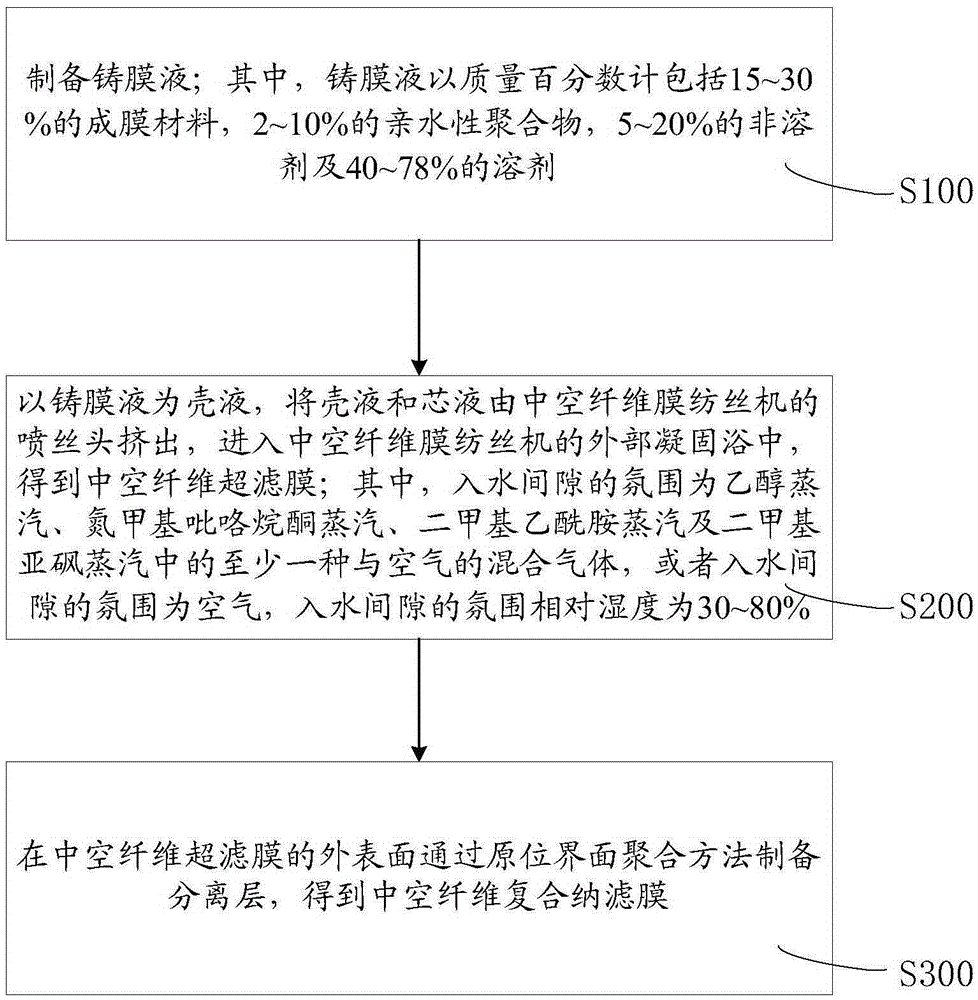

[0022] refer to figure 1 , the preparation method of the hollow fiber composite nanofiltration membrane of an embodiment includes the following steps.

[0023] Step S100: Prepare a casting solution; wherein, the casting solution includes 15-30% film-forming material, 2-10% hydrophilic polymer, 5-20% poor solvent and 40-78% solvent.

[0024] Wherein, poor solvent (nonsolvent) refers to the solvent that can not dissolve or has poor solubility for the film-forming material in the film-casting liquid, otherwise it is a solvent that can be miscible with the film-forming material in the film-casting liquid.

[0025] In one embodiment, the step of preparing the casting solution includes: mixing the film-forming material, the hydrophilic polymer, the poor solvent and the solvent, dissolving and degassing, and obtaining the casting solution.

[0026] Preferably, the film-forming material is at least one of polyethersulfone, polysulfone, polyvinyl chloride, polyvinylidene fluoride and...

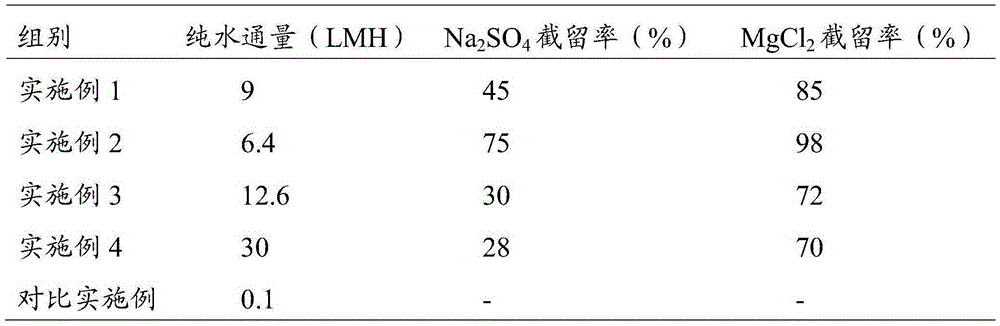

Embodiment 1

[0055] Mix 18g of polyethersulfone, 5g of sulfonated polyethersulfone, 5g of water and 72g of dimethylacetamide, stir for 24 hours to dissolve, and then stand for defoaming to obtain a uniform and transparent casting solution.

[0056] The distance of the water-entry gap of the spinneret is set to 10 cm, and the atmosphere of the water-entry gap is set to be a mixed gas of dimethyl sulfoxide steam and air, wherein the volume percentage of the air is 75%, and the relative humidity of the mixed gas is 40%. The core fluid is a 30% nitrogen methyl pyrrolidone aqueous solution at 50°C, and water at 25°C is used as the coagulant in the external coagulation bath. A hollow fiber membrane spinning machine is used, and the casting liquid is used as the shell liquid, and the shell liquid and the core liquid are extruded from the spinneret and entered into an external coagulation bath to obtain a hollow fiber ultrafiltration membrane. The hollow fiber ultrafiltration membrane was rinsed i...

Embodiment 2

[0059] Mix 15g of polyvinylidene fluoride, 10g of polyvinylpyrrolidone (K30), 20g of glycerin and 55g of nitrogen methylpyrrolidone, heat to 80°C, stir and dissolve, and defoam to obtain a casting solution.

[0060] The distance of the water entry gap of the spinneret is set to be 30cm, and the atmosphere of the water entry gap is set to be a mixed gas of dimethylacetamide steam and air, wherein the volume percentage of the air is 85%, and the relative humidity of the mixed gas is 80%. The core fluid is a 50% dimethylformamide aqueous solution at 50°C with a mass fraction of 50%, and water at 25°C is used as the coagulant in the external coagulation bath. A hollow fiber membrane spinning machine is used, and the casting liquid is used as the shell liquid, and the shell liquid and the core liquid are extruded from the spinneret and entered into an external coagulation bath to obtain a hollow fiber ultrafiltration membrane. The hollow fiber ultrafiltration membrane was rinsed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com