A sn-ag-cu low-silver lead-free solder containing nd, re, in

A lead-free solder and solder technology, used in welding/cutting media/materials, welding media, metal processing equipment, etc. The effect of creep resistance, growth inhibition and improvement of mechanical properties of lead-free solder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

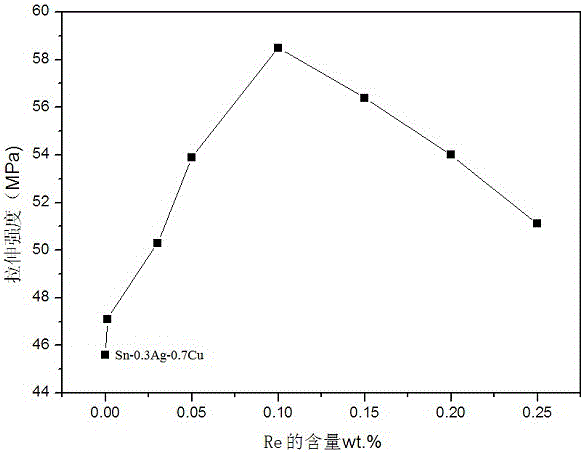

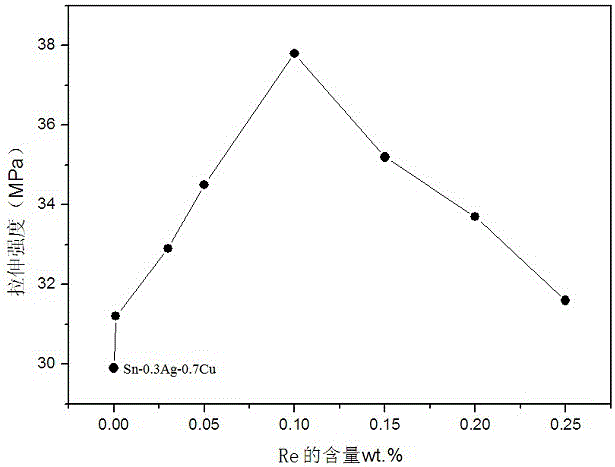

[0032] A Sn-Ag-Cu low-silver lead-free solder containing Nd, Re, and In, including the following components: Ag content of 0.1 wt.%, Cu content of 0.5 wt.%, and Re content of 0.001 wt.% , Nd content is 0.001 wt.%, In content is 0.001 wt.%, and the balance is Sn, which is directly mixed and smelted under the protection of nitrogen to prepare solder.

Embodiment 2

[0034] A Sn-Ag-Cu low-silver lead-free solder containing Nd, Re and In, including the following components: Ag content of 1.0 wt.%, Cu content of 2.0 wt.%, and Re content of 0.25 wt.% , Nd content is 0.1 wt.%, In content is 0.2 wt.%, the balance is Sn, and it is directly mixed and smelted under the protection of nitrogen to prepare solder.

Embodiment 3

[0036] A Sn-Ag-Cu low-silver lead-free solder containing Nd, Re, In, including the following components: Ag content of 0.2wt.%, Cu content of 0.6wt.%, Re content of 0.06wt. %, Nd content is 0.05 wt.%, In content is 0.1 wt.%, the balance is Sn, and the brazing filler metal is directly mixed and smelted under the protection of nitrogen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com