Manufacturing method of semi-flexible copper clad laminate

A manufacturing method and technology of copper clad laminates, applied in chemical instruments and methods, lamination auxiliary operations, lamination devices, etc., can solve the problems of poor dimensional stability of glass fiber cloth, unqualified PCB boards, affecting product quality, etc. Quality and performance, ensure product quality, avoid poor impregnation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

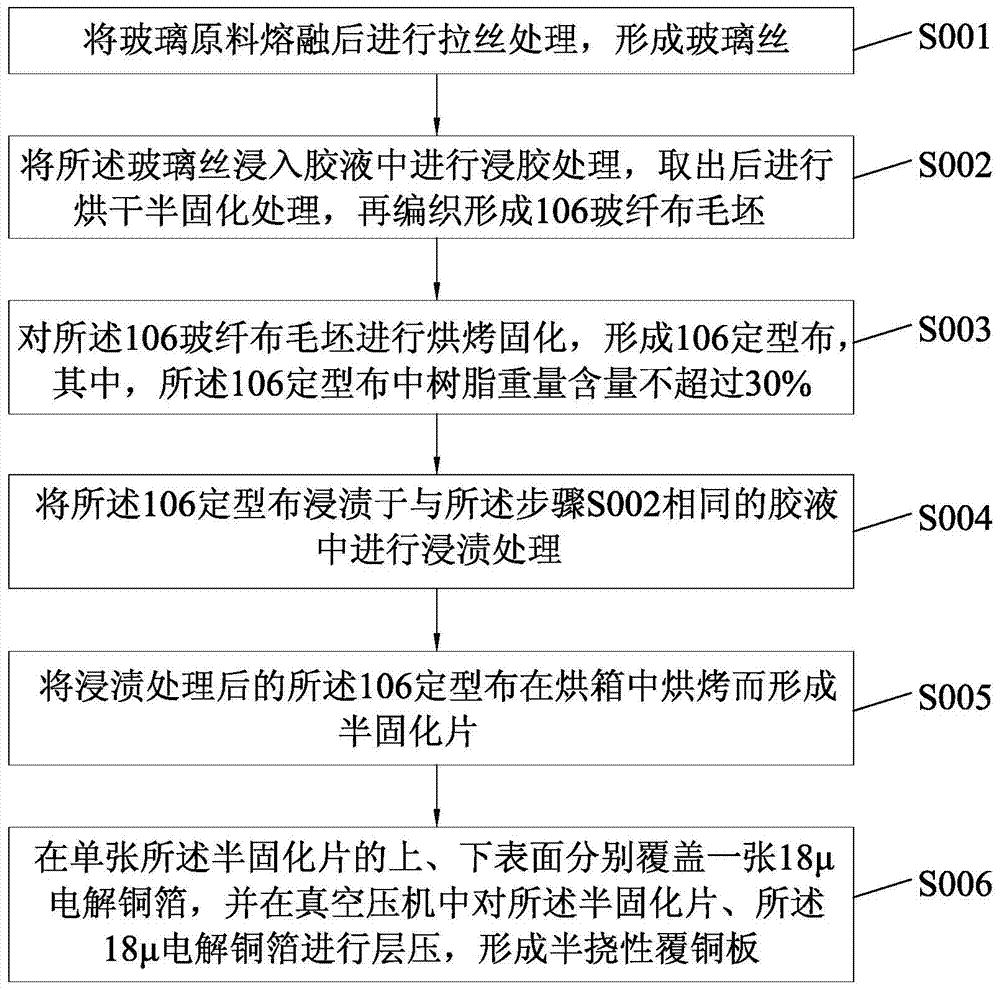

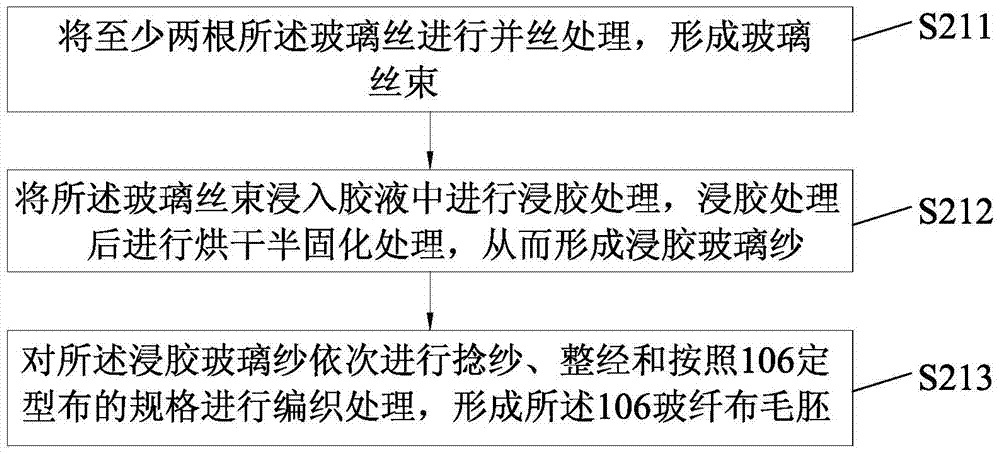

[0057] Through the above-mentioned first production method (such as figure 1 , 2 shown) to produce 106 shaped cloth, that is, glass raw materials are drawn to form glass filaments, and at least two glass filaments are paralleled to form glass filaments, and then resin composed of epoxy resin, curing agent and toughening agent is used The composition solution is used to impregnate the glass strands. After the impregnation, it is dried and semi-cured, and then twisted, warped, and weaved according to the specifications of 106 sizing cloths. After the weaving, it is dried in an oven at 170°C. After curing for 90 minutes, a 106 shaped cloth is obtained, and the resin weight content in the 106 shaped cloth does not exceed 30%. Subsequently, the 106 shaped cloth is dipped in a resin composition solution composed of epoxy resin, curing agent and toughening agent, etc. for impregnation treatment, and the 106 shaped cloth after the dipping treatment is baked in an oven at 155° C. for ...

Embodiment 2

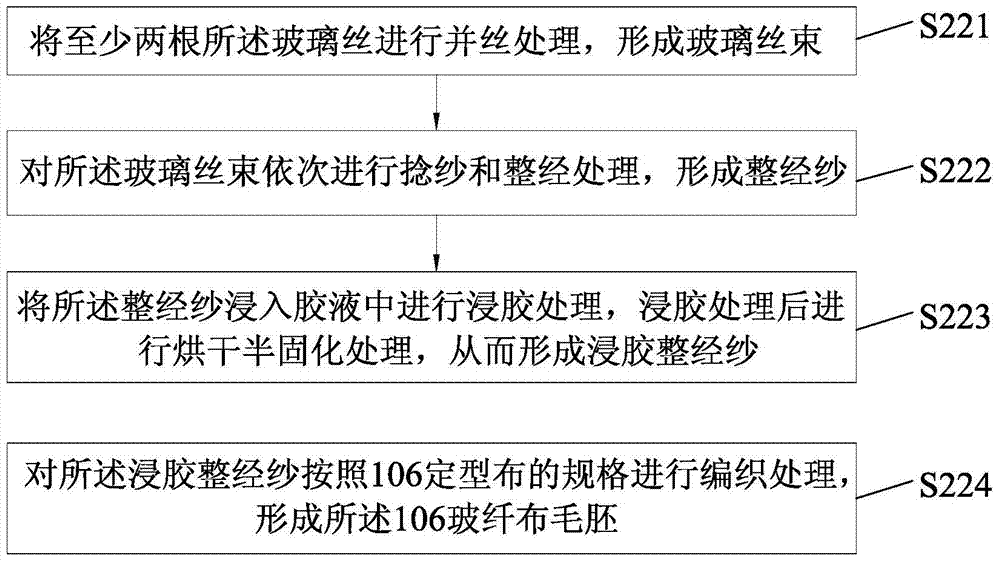

[0059] Through the second production method above (such as figure 1 , 3 shown) to produce 106 shaped cloths. Specifically, glass raw materials are drawn to form glass filaments, at least two glass filaments are paralleled to form glass filaments, and the glass filaments are sequentially twisted and warped to form Warp the warp yarn, and then use a resin composition solution composed of epoxy resin, curing agent and toughening agent to impregnate the warp yarn, dry and semi-cure the warp yarn after the dipping treatment, and then carry out according to the specifications of 106 sizing cloth Weaving treatment, after the weaving treatment, bake in an oven at 170°C for 90 minutes and solidify to obtain 106 shaped cloth, the weight content of resin in the 106 shaped cloth is not more than 30%. Subsequently, the 106 shaped cloth is dipped in a resin composition solution composed of epoxy resin, curing agent and toughening agent, etc. for impregnation treatment, and the 106 shaped c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com