A temperature-resistant and moisture-resistant capsule material for cigarettes and its application

A technology for capsules and cigarettes, which is applied in applications, microcapsule preparations, tobacco, etc. It can solve the problems of complex process, unsmooth dripping, and easy blockage of drippers, etc., and achieves extended storage time, simple manufacturing process, and excellent compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1 is used to illustrate the temperature-resistant and moisture-resistant capsule for cigarettes of the present invention and its preparation method.

[0057] 1. Raw materials

[0058] Material name The mass parts of each component gelatin 50 gum arabic 0.5 Sorbitol 5 Maltodextrin 10 Bright blue 0.05 Deionized water 100

[0059] 2. Preparation method

[0060] Weigh 10kg of deionized water, 50g of gum arabic, 0.5kg of sorbitol and 1kg of maltodextrin into the plastic tank, stir and heat to 65°C, after the mixture is completely dissolved, add 5kg of gelatin, continue to stir until the gelatin is completely dissolved, add 5g bright blue, stir for 30 minutes until the bright blue is completely dissolved, stop stirring, lower the heating temperature of the glue pot to 60°C, let it stand for 4 hours to remove air bubbles, pass through an 80-mesh sieve, and obtain a glue solution, the viscosity at 70°C is 916.8mPa.s....

experiment example 1

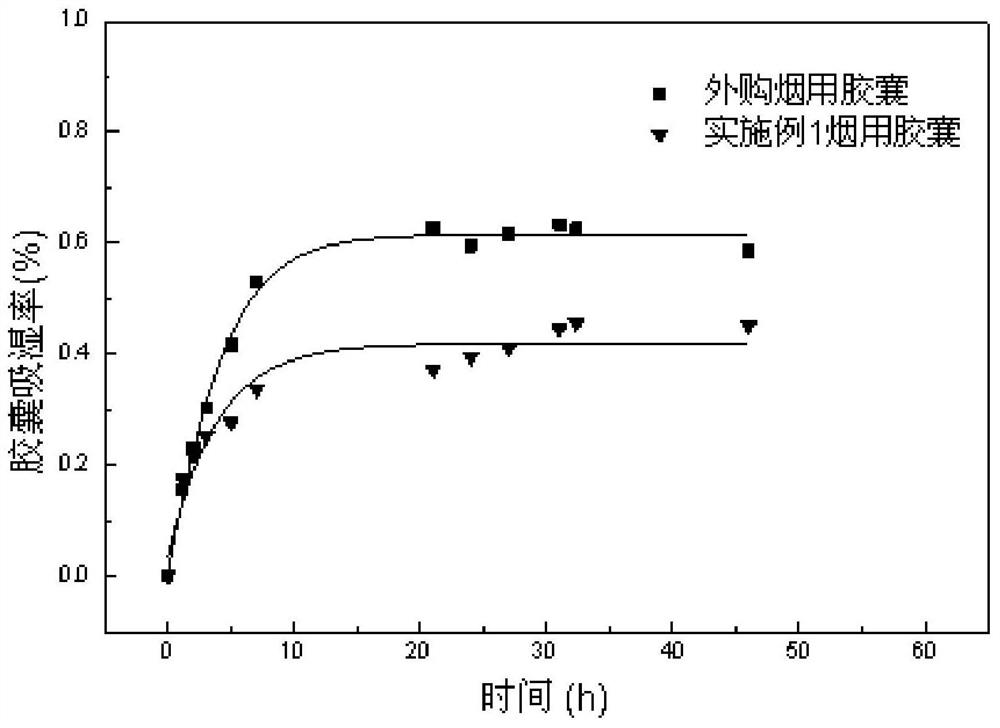

[0070] Put the purchased capsules and the capsules obtained in Example 1 into an environment with a temperature of 22° C. and a humidity of 60%, take them out and weigh them at regular intervals, and investigate the moisture absorption rate of the finished capsules. The capsule moisture absorption curve is as follows: figure 1 shown. Depend on figure 1 It can be seen that the moisture absorption rate of the capsules obtained in Example 1 is significantly lower than that of the purchased capsules, indicating that the capsules obtained in Example 1 have stronger temperature and humidity resistance.

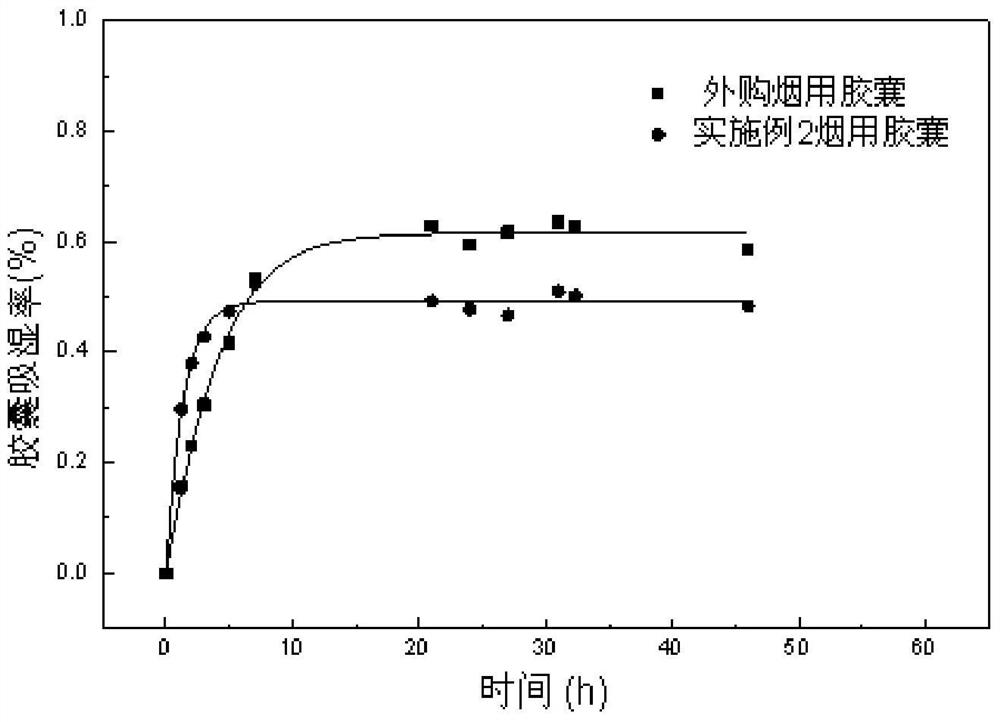

Embodiment 2

[0072] Example 2 is used to illustrate the temperature-resistant and moisture-resistant capsule for cigarettes of the present invention and its preparation method.

[0073] 1. Raw materials

[0074] Material name The mass parts of each component gelatin 50 Chitosan (acid soluble) 3 glycerin 1.5 Sorbitol 2 Maltodextrin 13 citric acid 6 Bright blue 0.05 Deionized water 100

[0075] 2. Preparation method

[0076] Weigh 10kg of deionized water, 0.6kg of citric acid, 0.3kg of chitosan, 0.15kg of glycerin, 0.2kg of sorbitol and 1.3kg of maltodextrin into the glue tank, stir and heat to 65°C. After the mixture is completely dissolved, Add 5kg of gelatin, continue to stir until the gelatin is completely melted, add 5g of brilliant blue, and stir for another 30 minutes until the brilliant blue is completely dissolved, stop stirring, lower the heating temperature of the glue tank to 60°C, let it stand for 4 hours to remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com