Novel silk swelling agent, and preparation method thereof

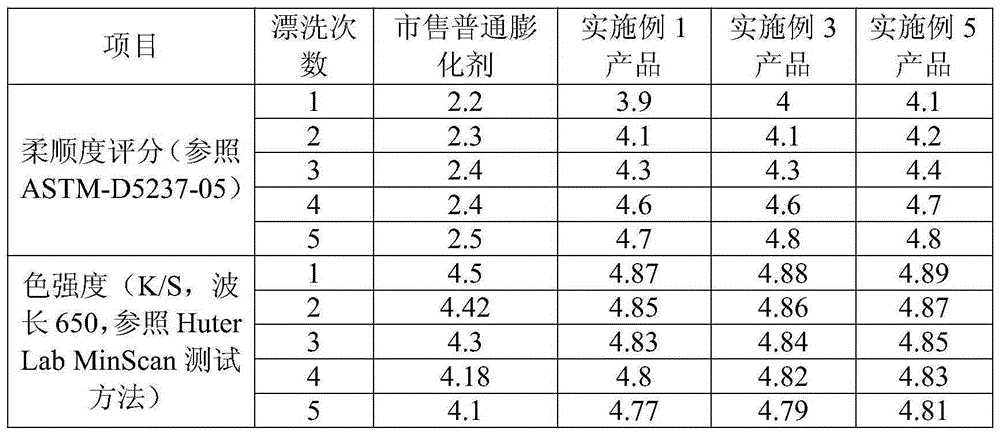

A silk bulking agent and a new type of technology, applied in textiles and papermaking, fiber processing, animal fibers, etc., can solve problems such as poor silk softness, fluffy, elasticity, etc., which cannot meet the actual production of factories, etc. Excellent bactericidal performance and outstanding biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A new type of silk swelling agent, in parts by weight, includes the following raw materials: 525 parts of unwinding agent and 48.3 parts of softening agent. The unwinding agent includes the following raw materials: Na 2 SiO 3 25 parts, 500 parts deionized water; the softener includes the following raw materials: 6 parts of ester quaternary ammonium salt, 0.3 parts of silane-modified polyurethane, 0.2 parts of polyether-modified silane, 0.1 parts of sodium lignosulfonate, alkyl 0.1 part of sodium benzene sulfonate, 0.2 part of sodium starch graft acrylate, 0.2 part of sodium polyacrylate, 0.2 part of sodium N-lauroyl glutamate, 0.2 part of calcium lignosulfonate, 0.2 part of citronellal, 0.3 part of malic acid , 0.1 part of carrageenan, 0.1 part of locust bean gum, 0.1 part of triadimefon, and 40 parts of deionized water.

[0028] The preparation method of the novel silk puffing agent includes the following steps:

[0029] S1: Add the ester quaternary ammonium salt to 40 part...

Embodiment 2

[0036] A new type of silk swelling agent, in parts by weight, includes the following raw materials: 1,050 parts of unwinding agent and 84.8 parts of softening agent. The unwinding agent includes the following raw materials: Na 2 SiO 3 35 parts, 1015 parts of deionized water; the softener includes the following raw materials: 10 parts of ester quaternary ammonium salt, 0.5 parts of silane-modified polyurethane, 0.4 parts of polyether-modified silane, 0.4 parts of sodium lignosulfonate, alkyl 0.3 parts of sodium benzenesulfonate, 0.4 parts of sodium starch graft acrylate, 0.3 parts of sodium polyacrylate, 0.4 parts of sodium N-lauroyl glutamate, 0.3 parts of calcium lignosulfonate, 0.5 parts of citronellal, 0.5 parts of malic acid , 0.3 parts of carrageenan, 0.2 parts of locust bean gum, 0.3 parts of triadimefon, and 70 parts of deionized water.

[0037] The preparation method of the novel silk puffing agent includes the following steps:

[0038] S1: Add the ester quaternary ammonium...

Embodiment 3

[0045] A new type of silk swelling agent, in parts by weight, includes the following raw materials: 780 parts of unwinding agent and 66.6 parts of softening agent. The unwinding agent includes the following raw materials: Na 2 SiO 3 30 parts, 750 parts deionized water; the softener includes the following raw materials: 8 parts ester quaternary ammonium salt, 0.4 parts silane-modified polyurethane, 0.3 parts polyether-modified silane, 0.3 parts sodium lignosulfonate, alkyl 0.2 part of sodium benzene sulfonate, 0.3 part of sodium starch graft acrylate, 0.2 part of sodium polyacrylate, 0.3 part of sodium N-lauroyl glutamate, 0.3 part of calcium lignosulfonate, 0.3 part of citronellal, 0.4 part of malic acid , 0.2 parts of carrageenan, 0.2 parts of locust bean gum, 0.2 parts of triadimefon, and 55 parts of deionized water.

[0046] The preparation method of the novel silk puffing agent includes the following steps:

[0047] S1: Add the ester quaternary ammonium salt to 55 parts of deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com