Urban underground comprehensive steel pipe gallery

An integrated pipe gallery and city technology, applied in the field of pipelines, can solve the problems of low space utilization rate, increased foundation excavation depth and engineering volume, and long construction period, so as to improve the clear width and clear height of the passage and reduce the amount of civil engineering. , the effect of reducing the excavation depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

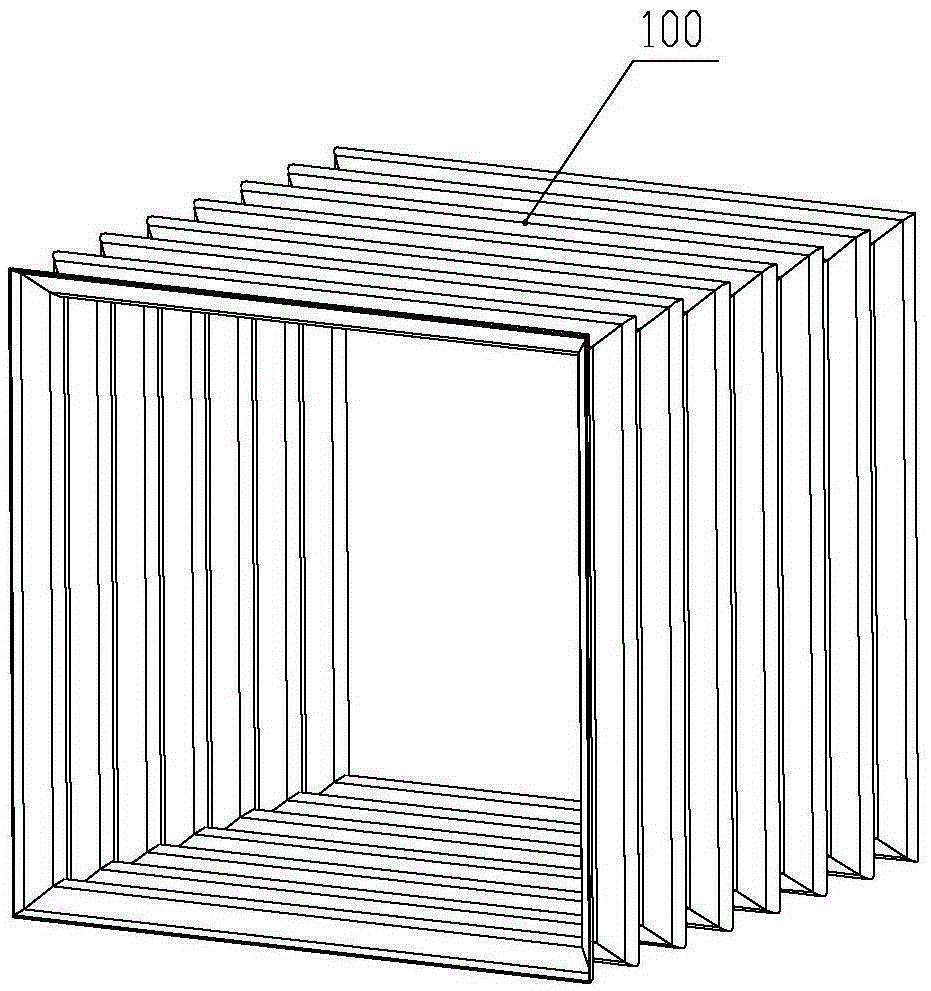

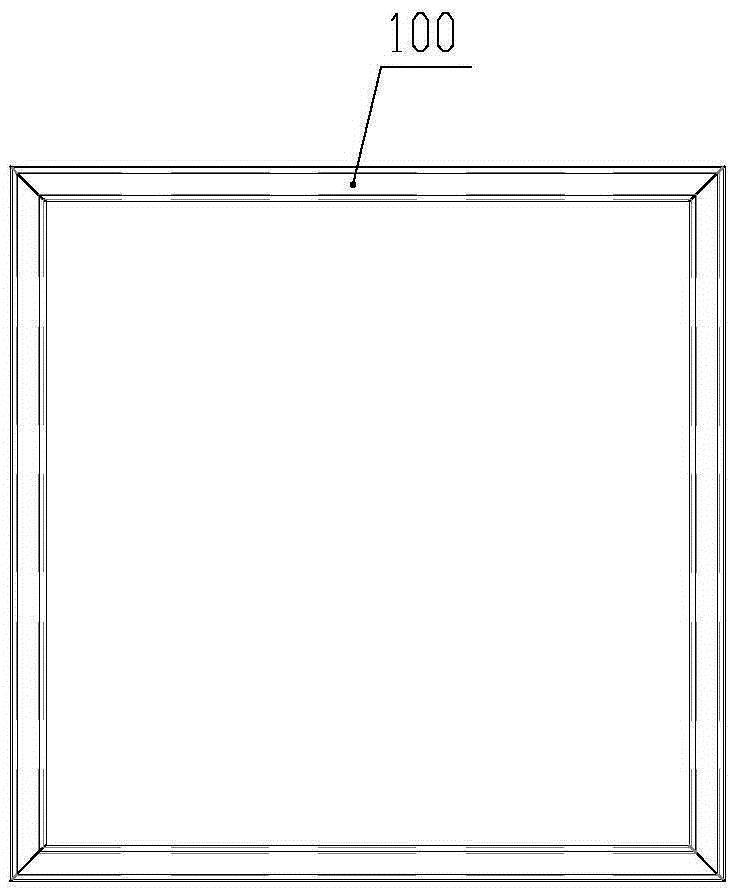

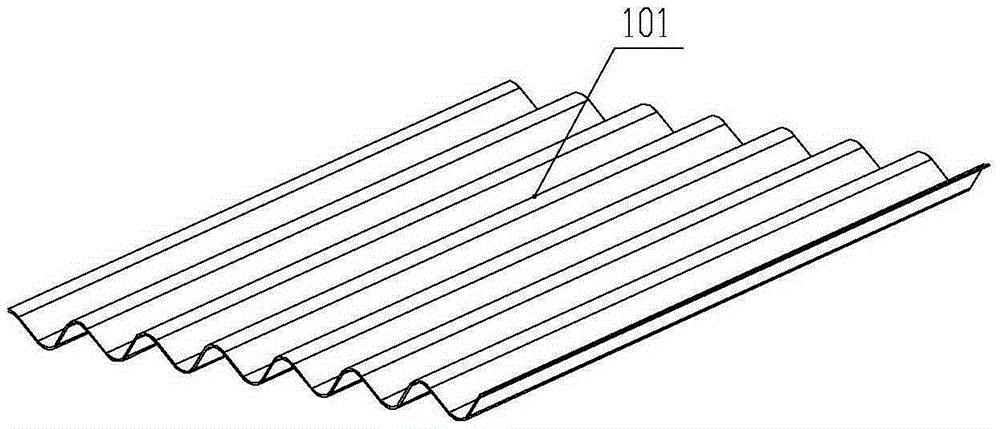

[0044] The first steel urban underground comprehensive pipe gallery 100 of the present invention includes a box-shaped pipe joint 102 formed by assembling unit plates 101. The box-shaped pipe joint 102 can be composed of two side unit plates and upper and lower unit plates. It can be composed of unit plates on both sides and upper unit plates. Such as Figure 11 The box-shaped pipe joints shown are rectangular. At the same time, the length of a single pipe gallery can be 15-25 meters. As long as the transportation conditions permit, the length can be longer, so that the joints of the entire pipe gallery are reduced and the sealing performance is better; the obtained The box-shaped pipe joints 102 are assembled in the axial direction to form a box-shaped pipe gallery 100; wherein, the outside and / or inside of the unit plate 101 has a protrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com