Anti-permeability performance test system for shield tunnel segment circumferential seams

A shield tunnel segment and test system technology, which is applied in the field of shield tunnel segment circumferential seam impermeability test system, can solve the problems of difficulty in accurately reflecting the waterproof sealing mechanism, small size of cover plate, low test accuracy, etc. The test results are true and reliable, the effect of reducing the processing cost and shortening the test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

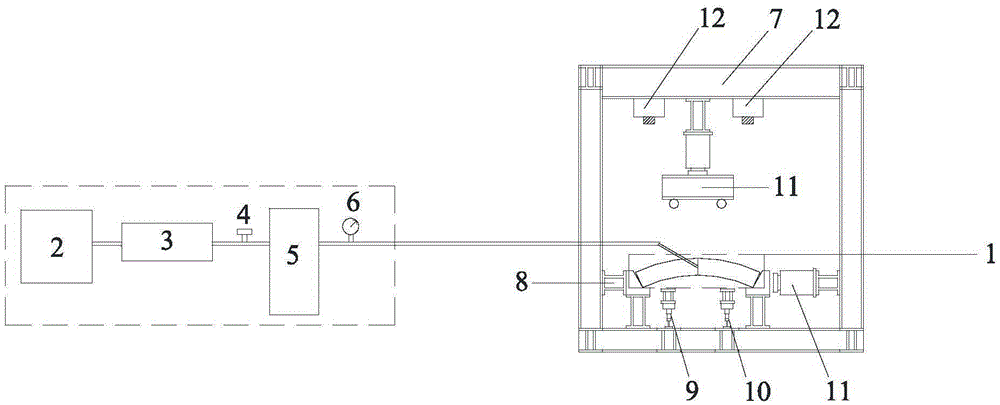

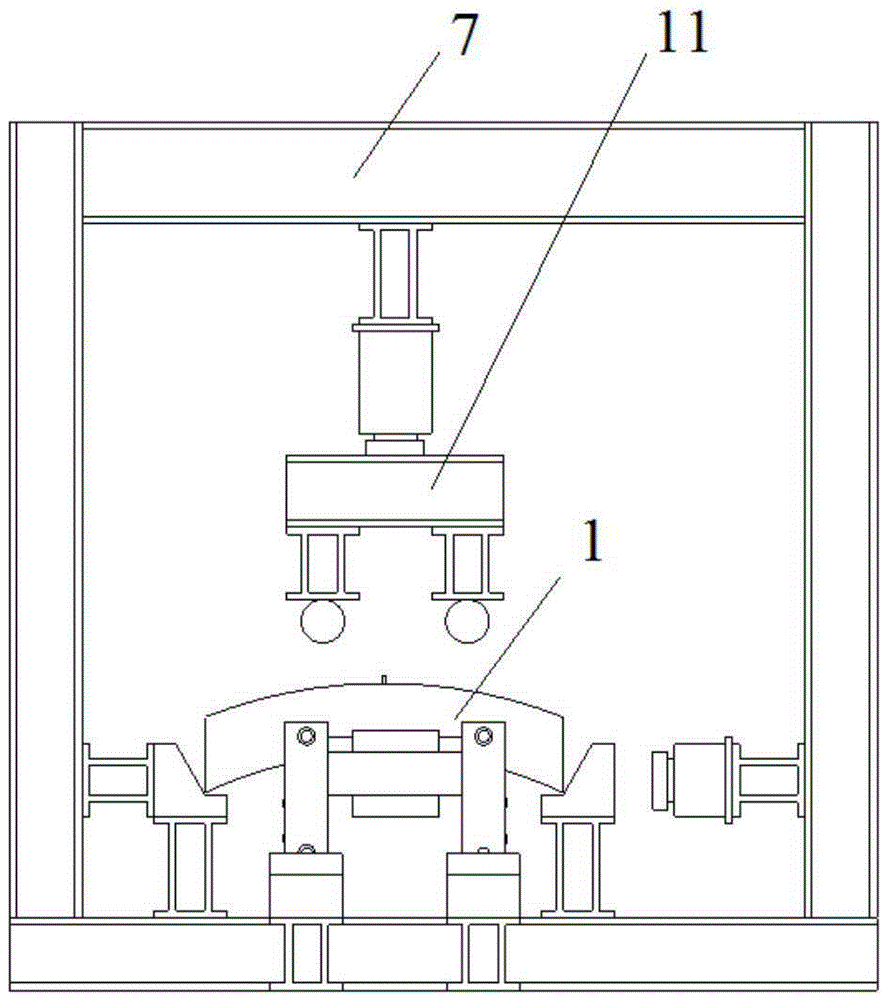

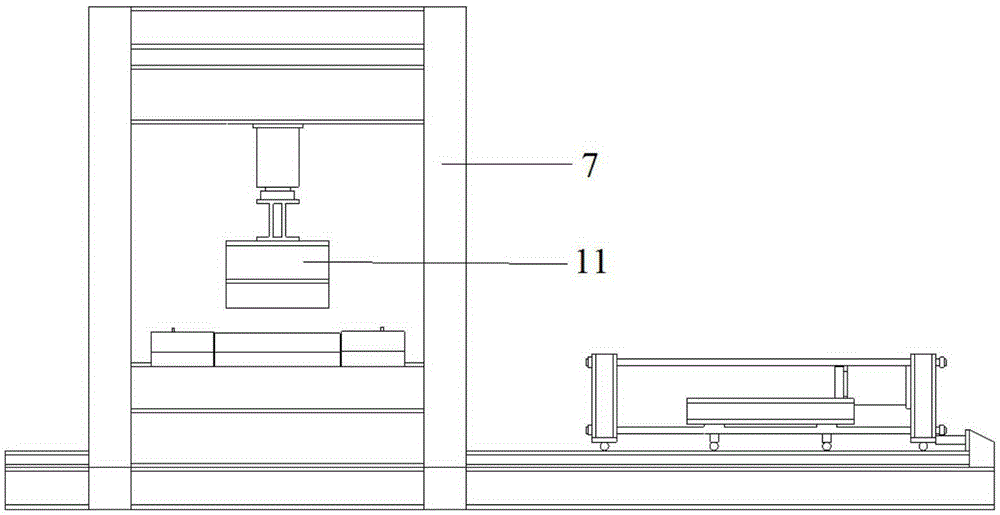

[0056]The test system for the impermeability of the annular joints of shield tunnel segments, the structure of which is as follows: figure 1 As shown in the figure, it mainly includes a segment specimen 1 used for the circumferential seam impermeability test, and a hydraulic loading assembly, which mainly includes a water supply tank 2, a hydraulic press 3, a hydraulic pressure gauge 6, a valve 4 and a water storage tank 5 with a scale. The hydraulic loading assembly and the frame 7 together form the segment loading assembly, such as Figure 2-4 shown. Observation and recording components mainly include laser displacement sensors and digital close-range photogrammetry equipment. Next, the above components will be further described in detail.

[0057] The specific structure of the segment test piece 1 is as follows: Figure 5-19 As shown, the segment test piece 1 is mainly composed of two types: A-type segment and B-type segment. Among them, A-type segment is composed of seg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com