Preparation method of thin film with Raman enhancing performance

A thin film and performance technology, applied in the field of magnetron sputtering to prepare Raman enhanced thin film substrates, can solve the problems of insufficient chemical stability, poor repeatability and stability, easy sulfidation and oxidation, etc., and achieve good Raman enhancement effect and stability. Good, high-sensitivity results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1. Prepare a 150nm silver and silicon dioxide nanocomposite film on a smooth substrate by magnetron sputtering and co-sputtering. The composition of the film is adjusted by the power of the silver target and the silicon dioxide target to ensure that the mass percentage of Ag is 30%;

[0016] 2. Continue sputtering a layer of 30nm nano-silver film on the surface of the composite film;

[0017] 3. Put the above film into an annealing furnace, heat to 920° C. under a protective atmosphere for annealing treatment, keep for 3 hours, and cool to room temperature.

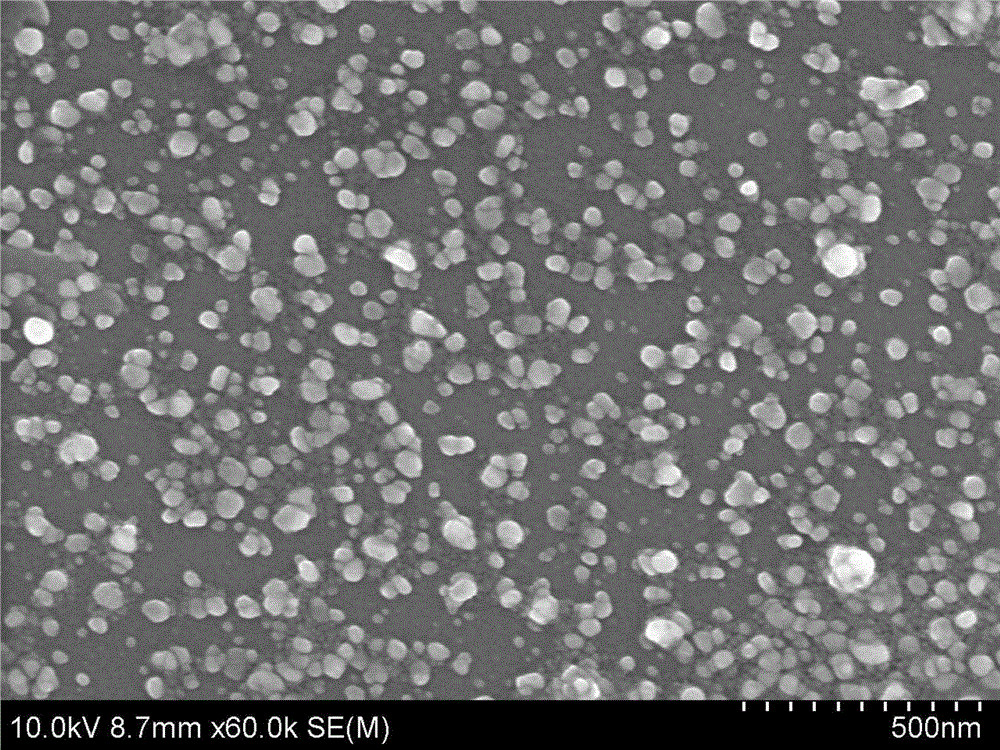

[0018] figure 1 It is the SEM image of the prepared nano film, it can be seen from the figure that nano silver particles are dispersed on the surface of the film.

Embodiment 2

[0020] 1. Prepare a 100nm silver and silicon dioxide nanocomposite film on a smooth substrate by magnetron sputtering co-sputtering. The targets used for sputtering are silver target and silicon dioxide target respectively. 0.8Pa, adjust the power of the silver target and the silicon dioxide target to ensure that the mass percentage of Ag is 70%;

[0021] 2. Continue sputtering a layer of 40nm nano-silver film on the surface of the composite film;

[0022] 3. Put the film above into an annealing furnace, heat it to 900° C. under a protective atmosphere for annealing treatment, keep it for 3 hours, and cool it down to room temperature.

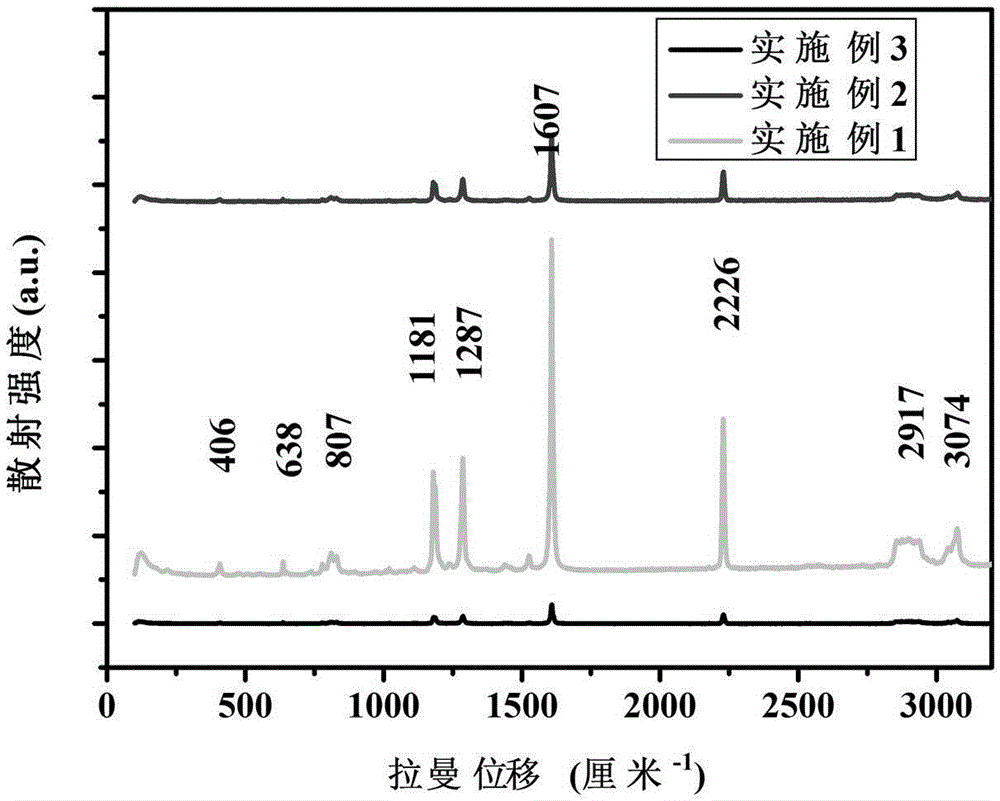

[0023] The prepared film substrate was used for detection of 5cb liquid crystal molecules.

Embodiment 3

[0025] 1. Prepare a 130nm silver and silicon dioxide nanocomposite film on a smooth substrate by magnetron sputtering co-sputtering. The targets used for sputtering are silver target and silicon dioxide target respectively. is 0.8Pa, and the film composition is adjusted by the power of the silver target and the silicon dioxide target to ensure that the mass percentage of Ag is 50%;

[0026] 2. Continue sputtering a layer of 50nm nano-silver film on the surface of the composite film;

[0027] 3. Put the above film into an annealing furnace, heat to 940° C. under a protective atmosphere for annealing treatment, keep it for 1 hour, and cool to room temperature.

[0028] The prepared film substrate was used for detection of 5cb liquid crystal molecules.

[0029] The Raman-enhanced thin film substrate prepared in the above examples has a simple preparation process, good repeatability, and the prepared thin film has stable performance, which can meet various detection application r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com