Flexible mechanical arm vibration active control method adopting piezoelectric ceramic sheet during soft measurement

A technology of flexible manipulators and piezoelectric ceramics, applied in general control systems, adaptive control, control/regulation systems, etc., can solve problems such as control overflow, complex system structure, and natural modes that affect the dynamic characteristics of flexible arms. Achieve the effect of reducing vibration observation error, simplifying system structure and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

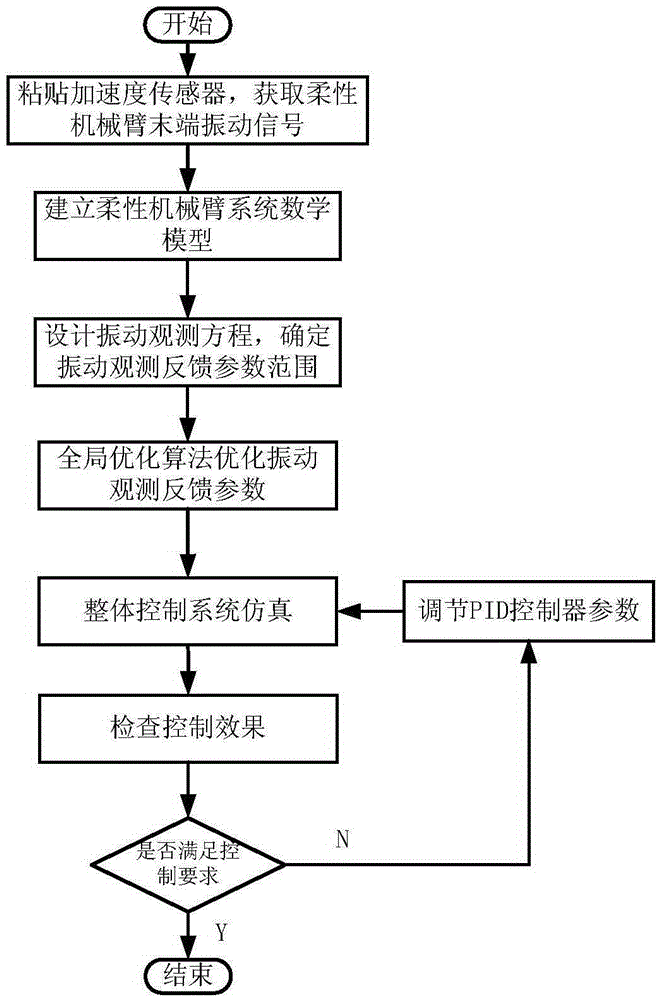

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing.

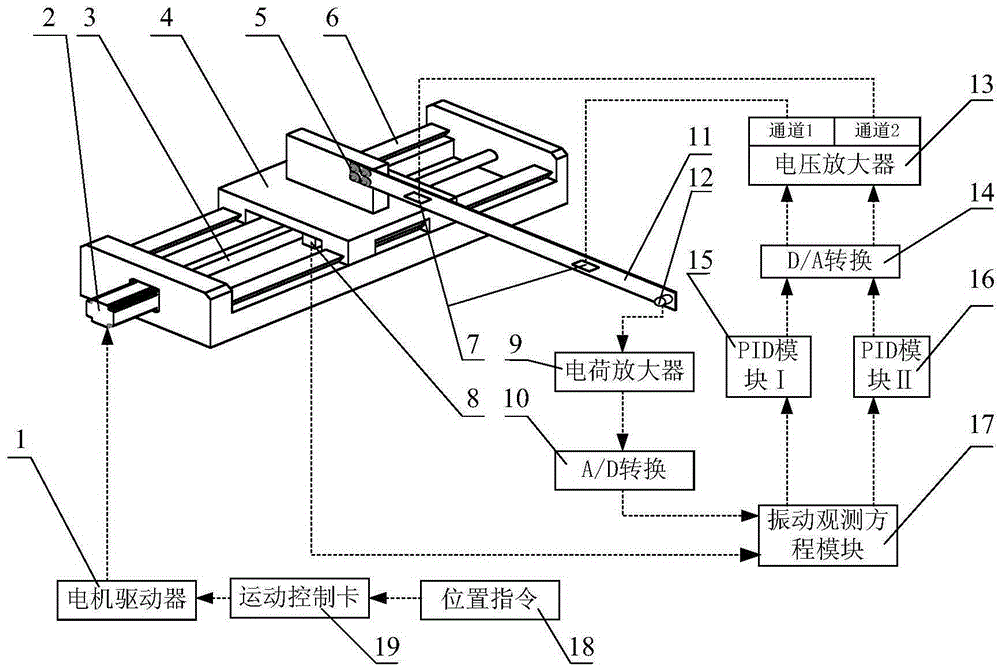

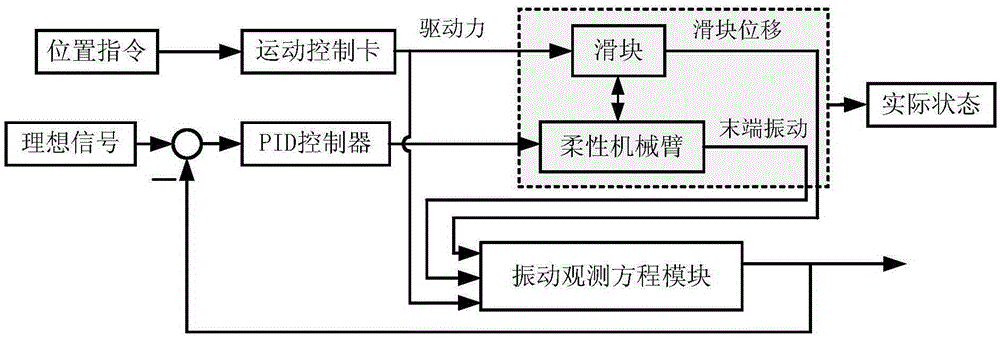

[0038] Such as figure 1 Shown is an active vibration control device for a flexible manipulator using piezoelectric ceramics under soft measurement, in which the stepping motor 2 drives the slider 4 to move on the guide rail 6 through the ball screw 3, and the bolt 5 controls the vibration of the flexible manipulator 11. One end is rigidly connected with slider 4;

[0039] The displacement of the slider 4 is measured by a grating ruler 8 , and the vibration at the end of the flexible mechanical arm 11 is measured by an acceleration sensor 12 . The output signal of the acceleration sensor 12 is input to the vibration observation equation module 17 through the charge amplifier 9 and the A / D conversion module 10;

[0040] The position instruction module 18 sets the expected position of the slider 4, and drives the stepper motor 2 to move the slider 4 to the designated positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com