Electrolyte for improving high temperature and high voltage performance of lithium ion battery and application thereof in lithium ion battery

A lithium-ion battery and electrolyte technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problems of enhanced activity of electrode materials, decreased battery cycle performance, increased side reactions, etc., to achieve excellent high-temperature storage performance, maintaining high-temperature storage performance, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

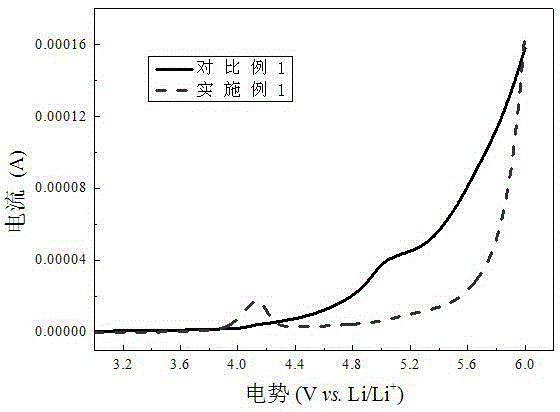

Problems solved by technology

Method used

Image

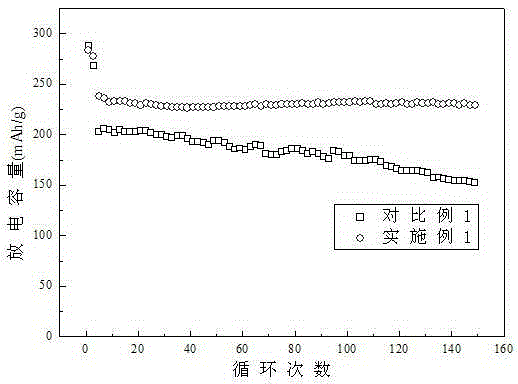

Examples

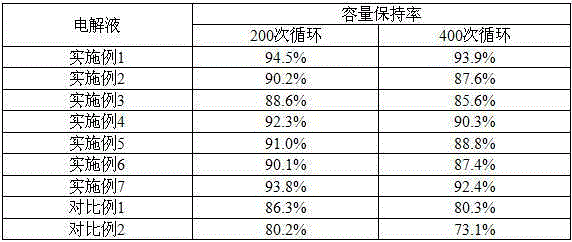

Embodiment 1

[0025] Mix 20wt.% ethylene carbonate (EC), 60wt.% dimethyl carbonate (DMC) and 20wt.% fluoroethylene carbonate (FEC) evenly, remove water and impurities with molecular sieve, dissolve 1mol / L lithium hexafluorophosphate into mixed solvent, and then add 0.2wt.% MDP and 0.5wt.% VC to obtain the electrolyte.

Embodiment 2

[0027] Mix 20wt.% ethylene carbonate (EC), 30wt.% dimethyl carbonate (DMC), 30wt.% diethyl carbonate (DEC) and 20wt.% fluoroethylene carbonate (FEC), and remove Remove impurities with water, dissolve 1mol / L lithium hexafluorophosphate into a mixed solvent, and then add 0.01wt.%MDP, 0.5wt.%VC and 0.5wt.%LiBOB to obtain the electrolyte.

Embodiment 3

[0029] Mix 20wt.% ethylene carbonate (EC), 60wt.% dimethyl carbonate (DMC) and 20wt.% fluoroethylene carbonate (FEC) evenly, remove water and impurities with molecular sieve, dissolve 1mol / L lithium hexafluorophosphate into The electrolyte solution can be obtained by adding 2wt.%MDP, 0.5wt.%VC, 0.5wt.%ES and 0.5wt.%BS to the mixed solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com