Fermented soybean peptides with low lipophilicity protein and production method of fermented soybean peptides

A production method and technology of fermented soybean protein, which is applied in the field of fermented soybean peptide production, can solve the problems of unsuitable soybean protein, complex processing methods, small isoelectric point range, etc., so as to avoid the generation of bad flavor, wide application space, Improve the effect of flavor problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

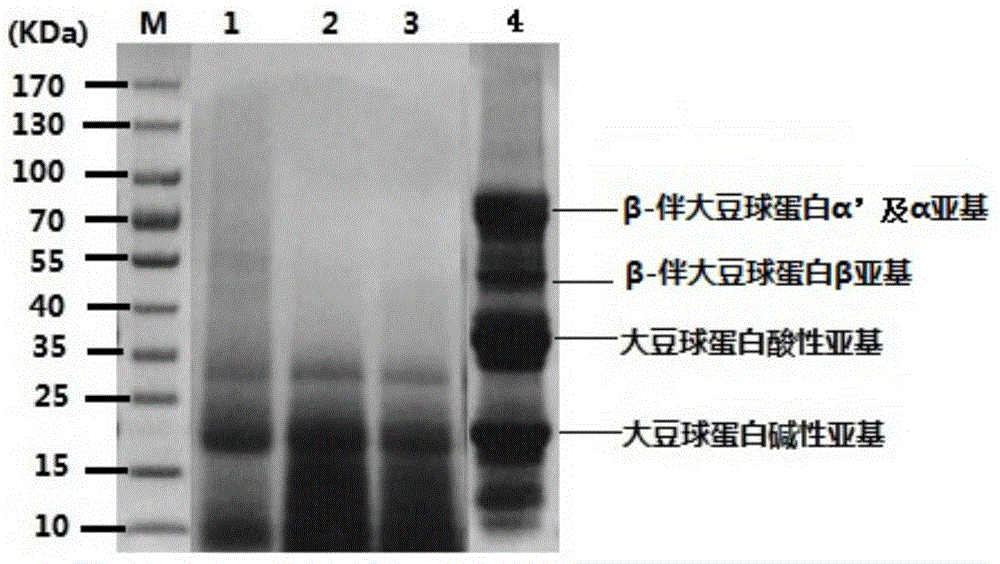

Image

Examples

Embodiment 1

[0072] Embodiment 1: raw material preparation

[0073] The fermented soybean meal raw material of the embodiment of the present invention is self-made fermented soybean meal, and the method of self-made fermented soybean meal is as follows:

[0074] Sterile water is added into the soybean meal to make the water content of the soybean meal 45%-50%. Inoculate complex bacterial preparations (60% for Bacillus subtilis, 30% for Saccharomyces cerevisiae, and 10% for lactic acid bacteria) in the soybean meal after adding water, carry out ventilated fermentation at 35°C-40°C, and dry and pulverize after 36 hours of fermentation , to obtain a self-made fermented soybean meal product, the product quality is shown in Table 1 after testing, and the self-made fermented soybean meal is a high-quality fermented soybean meal.

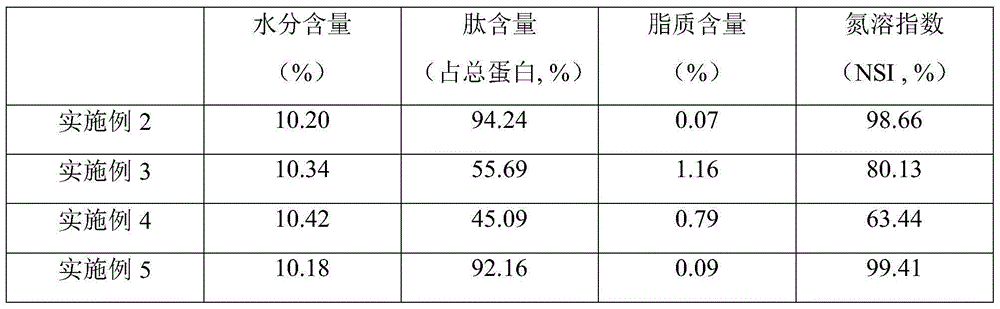

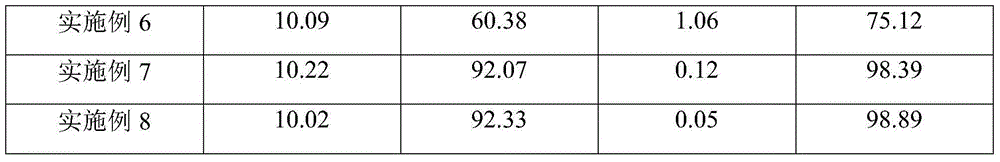

[0075] Table 1:

[0076]

Embodiment 2

[0077] Example 2: Preparation of fermented soybean peptides of low lipophilic protein

[0078] 1. Preparation of fermented soybean protein: Dissolve the self-made fermented soybean meal obtained in Example 1 in water at a ratio of 1:8 (w / w), adjust the pH to 8.0, and stir at 40°C for 1 hour to prepare a fermented soybean protein mixture. The mixture is prepared in 4000g Centrifuge for 10 minutes, separate the supernatant, re-dissolve the precipitated substance in water at 1:8 (w / w), repeat the extraction, centrifuge, collect the supernatant, combine the supernatant, and use it as a fermented soybean protein mixture;

[0079] 2. Fermented soybean peptide extraction: add Na to the fermented soybean protein mixture 2 SO 4 and CaCl 2 , so that the concentration reaches 1mM respectively, and adjust the pH to 5.8, centrifuge at 4000g for 10min, collect the supernatant, which is the fermented soybean peptide extract;

[0080] 3. Remove lipophilic protein: Add Na2SO3 to the ferment...

Embodiment 3

[0086]Embodiment 3: Preparation of fermented soybean peptide by Samoto method

[0087] Refer to the Samoto method (SamotoM, MaebuchiM, MiyazakiC, etal. Abundantproteins associated with lecithininsoyproteinisolate. FoodChemistry.2007, 102: 317-322.) to prepare fermented soybean peptides, the specific process is as follows:

[0088] Dissolve the self-made fermented soybean meal obtained in Example 1 in water at a ratio of 1:8 (w / w), adjust the pH to 8.0, and stir at 40°C for 1 hour to prepare a fermented soybean protein mixture. The mixture is centrifuged, and the precipitated substances are repeatedly extracted and combined. Supernatant, as a fermented soybean protein mixture; add Na to the fermented soybean protein mixture 2 SO 3 , make the concentration reach 1mM, and adjust the pH of the mixture to 5.0, heat and stir at 55°C for 15 minutes, adjust the pH to 5.5, centrifuge at 4000g for 10 minutes, collect the supernatant, which is the low lipophilic protein fermented soybea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com